Concentrated feed for pigs and preparation method thereof

A technology of concentrated feed and raw materials, applied in animal feed, animal feed, applications, etc., can solve the problems of poor nutritional stability and easy loss, and achieve the effects of low cost, improved stability, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

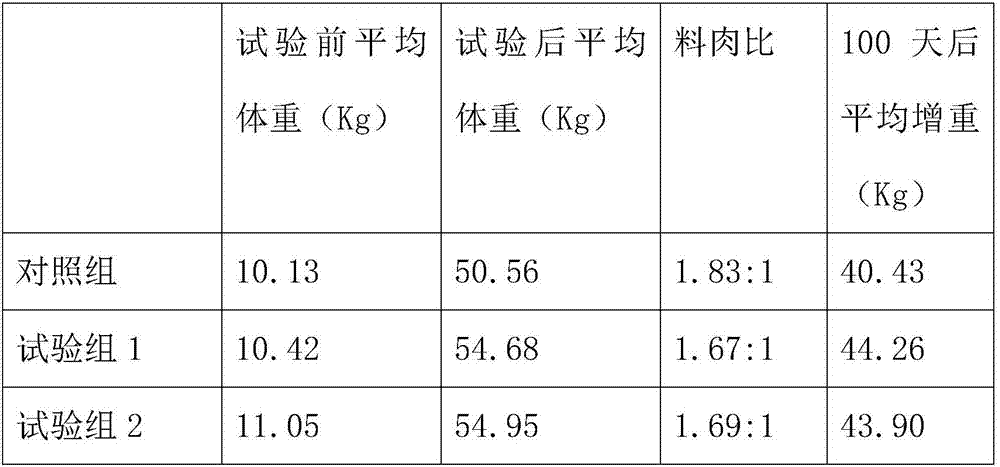

Examples

Embodiment 1

[0023] A concentrated feed for pigs, which is made up of the following raw materials in parts by weight:

[0024] Calcium dihydrogen phosphate 4, zinc sulfate 0.6, riboflavin 0.05, thiamine nitrate 0.5, sodium chloride 4, soybean meal 300, lychee shell 14, rehmannia glutinosa 2, palm kernel meal 50, oil residue 5, chelating emulsion 30, Barley vinegar grains 13, sodium bisulfite 2, potato pulp 40, tocopheryl acetate 0.2.

[0025] Described chelating emulsion is made up of the raw material of following weight part:

[0026] EDTA 4, Ferrous Sulfate 15, Copper Sulfate 4, Manganese Sulfate 3, Sorbitan Monostearate 1, Licorice 7, Chuanqiong 4;

[0027] The preparation method of described chelating emulsion comprises the following steps:

[0028] (1) Mix licorice and Chuanqiong, add to deionized water 40 times the weight of the mixture, heat to boiling, keep boiling for 15 minutes, filter, add sorbitan monostearate in the filtrate, stir to normal temperature, and obtain extract e...

Embodiment 2

[0038] A concentrated feed for pigs, which is made up of the following raw materials in parts by weight:

[0039] Calcium dihydrogen phosphate 3, zinc sulfate 0.5, riboflavin 0.03, thiamine nitrate 0.3, sodium chloride 2, soybean meal 270, lychee shell 10, Rehmannia glutinosa 1, palm kernel meal 40, oil residue 3, chelating emulsion 28, Barley vinegar grains 10, sodium bisulfite 1, potato pulp 30, tocopheryl acetate 0.1.

[0040] Described chelating emulsion is made up of the raw material of following weight part:

[0041] EDTA 3, ferrous sulfate 10, copper sulfate 3, manganese sulfate 2, sorbitan monostearate 0.4, licorice 5, Chuanqiong 3;

[0042] The preparation method of described chelating emulsion comprises the following steps:

[0043] (1) Mix licorice and Chuanqiong, add to deionized water 30 times the weight of the mixture, heat to boiling, keep boiling for 10 minutes, filter, add sorbitan monostearate in the filtrate, stir to normal temperature, and obtain extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com