Banana peel enzyme fermentation method

A peel enzyme and banana peel technology, applied in the field of banana peel enzyme fermentation, can solve the problem of banana peel polluting the environment, etc., and achieve the effects of increasing lipase content, refreshing aroma and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

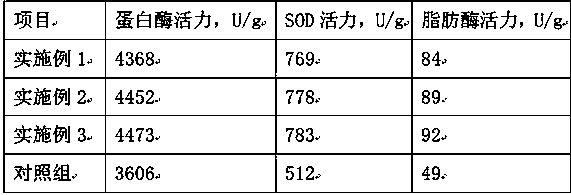

Examples

Embodiment 1

[0016] A method for fermenting banana peels, comprising the following steps:

[0017] (1) After washing the banana peel, chop it into pieces and soak it in the soaking solution for 3 hours, then filter it, and subject the banana peel residue to enzymatic compound enzymolysis, wherein the soaking solution is made of the following components by weight: Chlorinated 1 part potassium, 8 parts L-cysteine hydrochloride, 6 parts disodium DL-malate, 190 parts water;

[0018] (2) Sterilize the enzymatically hydrolyzed banana peel residue, inoculate the activated strain, and ferment for 3 days to obtain a banana peel fermentation liquid;

[0019] (3) In parts by weight, 38 parts of banana peel fermentation broth, 1 part of α-arbutin, 0.2 part of thiamine nitrate, and 1 part of creatine phosphate disodium salt were evenly mixed, and then added to a vacuum freeze dryer. Dried to a moisture content of 3.5% to obtain enzyme powder.

[0020] Specifically, in the above step (1), the proces...

Embodiment 2

[0024] A method for fermenting banana peels, comprising the following steps:

[0025] (1) After washing the banana peel, chop it into pieces and soak it in the soaking solution for 3.5 hours, then filter it, and subject the banana peel residue to enzymatic compound enzymolysis, wherein the soaking solution is made of the following components by weight: Chlorinated 3 parts of potassium, 10 parts of L-cysteine hydrochloride, 8 parts of disodium DL-malate, 195 parts of water;

[0026] (2) Sterilize the enzymatically hydrolyzed banana peel residue, inoculate the activated strain, and ferment for 3.5 days to obtain a banana peel fermentation liquid;

[0027] (3) In parts by weight, 40 parts of banana peel fermentation broth, 3 parts of α-arbutin, 0.3 parts of thiamine nitrate, and 2 parts of creatine phosphate disodium salt were evenly mixed, and then added to a vacuum freeze dryer. Dry to a moisture content of 2% to obtain enzyme powder.

[0028] Specifically, in the above ste...

Embodiment 3

[0032] A method for fermenting banana peels, comprising the following steps:

[0033] (1) After washing the banana peel, chop it into pieces and soak it in the soaking solution for 4 hours, then filter it, and carry out compound enzyme enzymolysis on the banana peel residue, wherein the soaking solution is made of the following components by weight: Chlorinated Potassium 5 parts, L-cysteine hydrochloride 12 parts, DL-disodium malate 11 parts, water 200 parts;

[0034] (2) Sterilize the enzymatically hydrolyzed banana peel residue, inoculate the activated strain, and ferment for 4 days to obtain a banana peel fermentation liquid;

[0035] (3) In parts by weight, 44 parts of banana peel fermentation broth, 4 parts of α-arbutin, 0.5 parts of thiamine nitrate, and 3 parts of creatine phosphate disodium salt were evenly mixed, and then added to a vacuum freeze dryer. Dry to a moisture content of 0.5% to obtain enzyme powder.

[0036] Specifically, in the above step (1), the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com