Trifluoromethyl substituted perylene bis diimines and preparation method thereof

A technology of perylene bis-diimide and trifluoromethyl, which is applied in the field of organic chemical industry and fine chemical industry to achieve the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

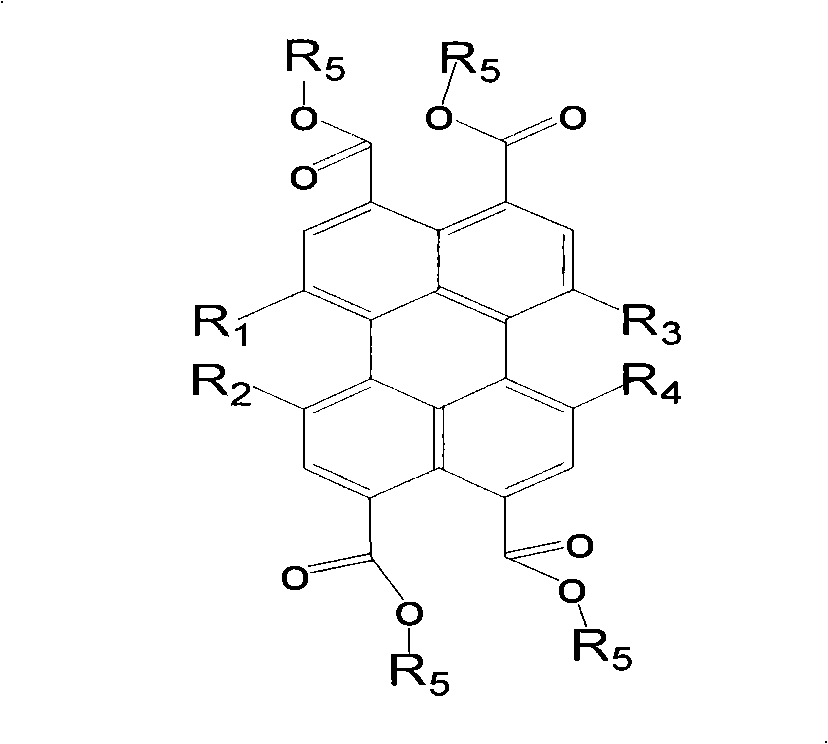

[0034] Example 1: Preparation of 1,7-ditrifluoromethyl-N,N'-dibutylperylene bisdiimide

[0035]

[0036] The synthetic route of this compound is shown in the figure above, which is synthesized through the following four steps:

[0037] (1) Synthesis of a mixture of 1,7-dibromoperylenetetracarboxylate tetrabutyl ester and 1,6-dibromoperylenetetracarboxylate tetrabutyl ester, add 820mg perylenetetracarboxylate (1.24mmol), 306mg to a 100mL two-neck bottle K 2 CO 3 (2.2mmol), 60mL CH 2 Cl 2 , Add 4mL liquid bromine (78.4mmol), keep the system at 10℃ under stirring, react for 2h, pass through a silica gel column to obtain 1,7-dibromoperylenetetracarboxylic acid tetrabutyl ester and 1,6-dibromoperylenetetracarboxylic acid tetrabutyl ester 600mg of ester mixture, 60% yield, API-ES-MS, [M+Na] + : 831(m / z); 1 H-NMR (400Mz, CDCl3): δ = 0.85-1.85 (m, 28H), 4.35 (m, 8H), 8.03 (m, 2H, perylene ring), 8.31 (m, 2H, perylene ring), 8.83 (m , 2H, perylene ring); 13 C-NMR(100MHz, CDCl 3 ): δ=14.0...

Embodiment 2

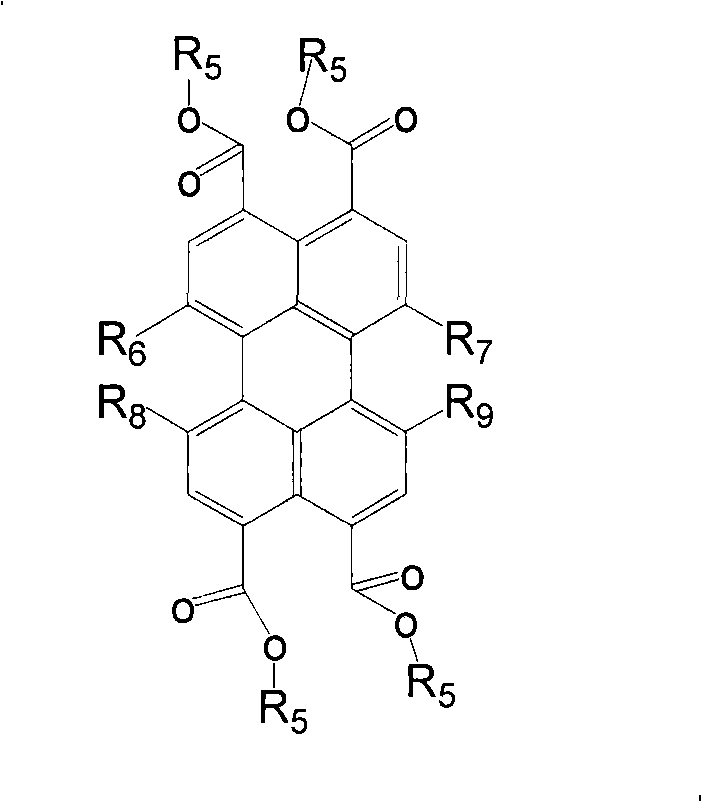

[0043] Example 2: Preparation of tetrabutyl 1-bromoperylenetetracarboxylate

[0044]

[0045] Add 3.0g tetrabutyl perylenetetracarboxylate (4.6mmol) to a 100mL two-necked bottle, 3.0g K 2 CO 3 (22mmol), 50mL CH2Cl2, add 3mL liquid bromine (59mmol), while stirring, keep the system at 20℃, react for 1.5h, and pass through a silica gel column to obtain 900mg of 1-bromoperylenetetracarboxylic acid tetrabutyl ester with a yield of 27%. API- ES-MS, [M+Na] + : 753(m / z); 1 H-NMR (400Mz, CDCl3): δ = 0.85-1.85 (m, 28H), 4.36 (m, 8H), 7.97 (d, 1H, perylene ring), 8.02 (d, 2H, perylene ring), 8.10 (m , 2H, perylene ring), 8.26 (s, 1H, perylene ring), 8.98 (d, 1H, perylene ring); 13 C-NMR(100MHz, CDCl 3 ): δ=13.8, 19.2, 19.3, 30.6, 65.4, 65.5, 65.7, 118.6, 121.6, 122.6, 127.3, 128.0, 129.2, 129.5, 130.0, 130.1, 130.2, 130.4, 130.8, 130.9, 131.6, 132.1, 132.4, 132.5, 137.4.

Embodiment 3

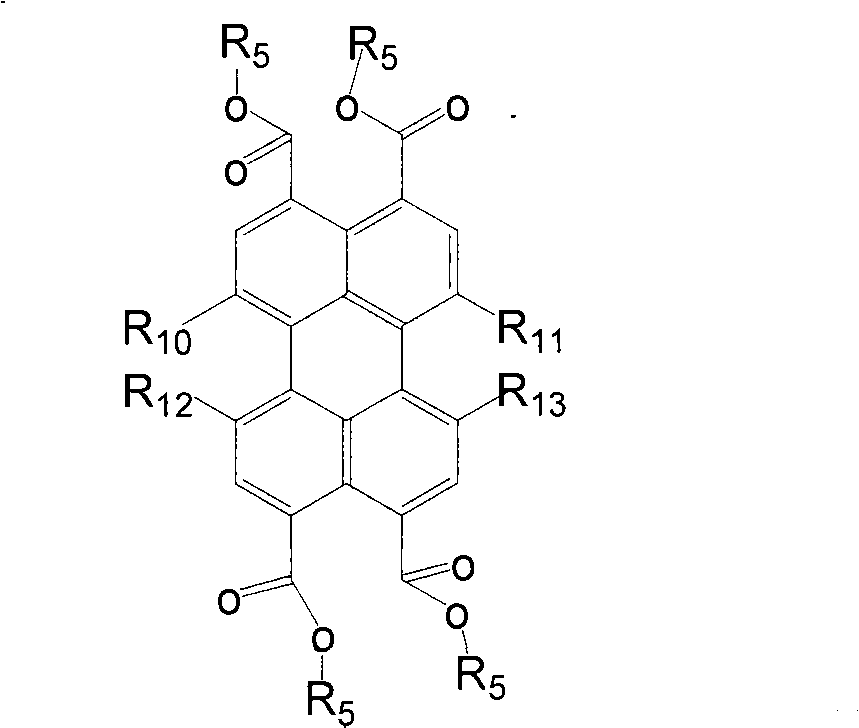

[0046] Example 3: Preparation of 1,6,7-tribromoperylenetetracarboxylic acid tetrabutyl ester and 1,6,7,12-tetrabromoperylenetetracarboxylic acid tetrabutyl ester

[0047]

[0048] Add 410mg tetrabutyl perylenetetracarboxylate (0.62mmol), 552mg K to a 25mL two-neck bottle 2 CO 3 (4mmol), 15mL of chlorobenzene, add 1mL of liquid bromine (19.6mmol), keep the system at 80°C under stirring, react for 48h, and pass through a silica gel column to obtain 110mg of 1,6,7-tribromoperylenetetracarboxylate tetrabutyl ester. Rate 19% API-ES-MS, [M+Na] + :908(m / z) and 1,6,7,12-tetrabromoperylenetetracarboxylic acid tetrabutyl ester 300mg, yield 50%, API-ES-MS, [M+Na] + : 986(m / z).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com