Preparation method of lithium bis (fluorosulfonyl) imide and lithium bis (fluorosulfonyl) imide

A technology of lithium bisfluorosulfonimide and imidic acid, which is applied in the directions of nitrosyl chloride, nitrogen and non-metallic compounds, can solve the problems of difficult operation, complex product composition and high cost, and achieves high yield and preparation. The effect of low process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

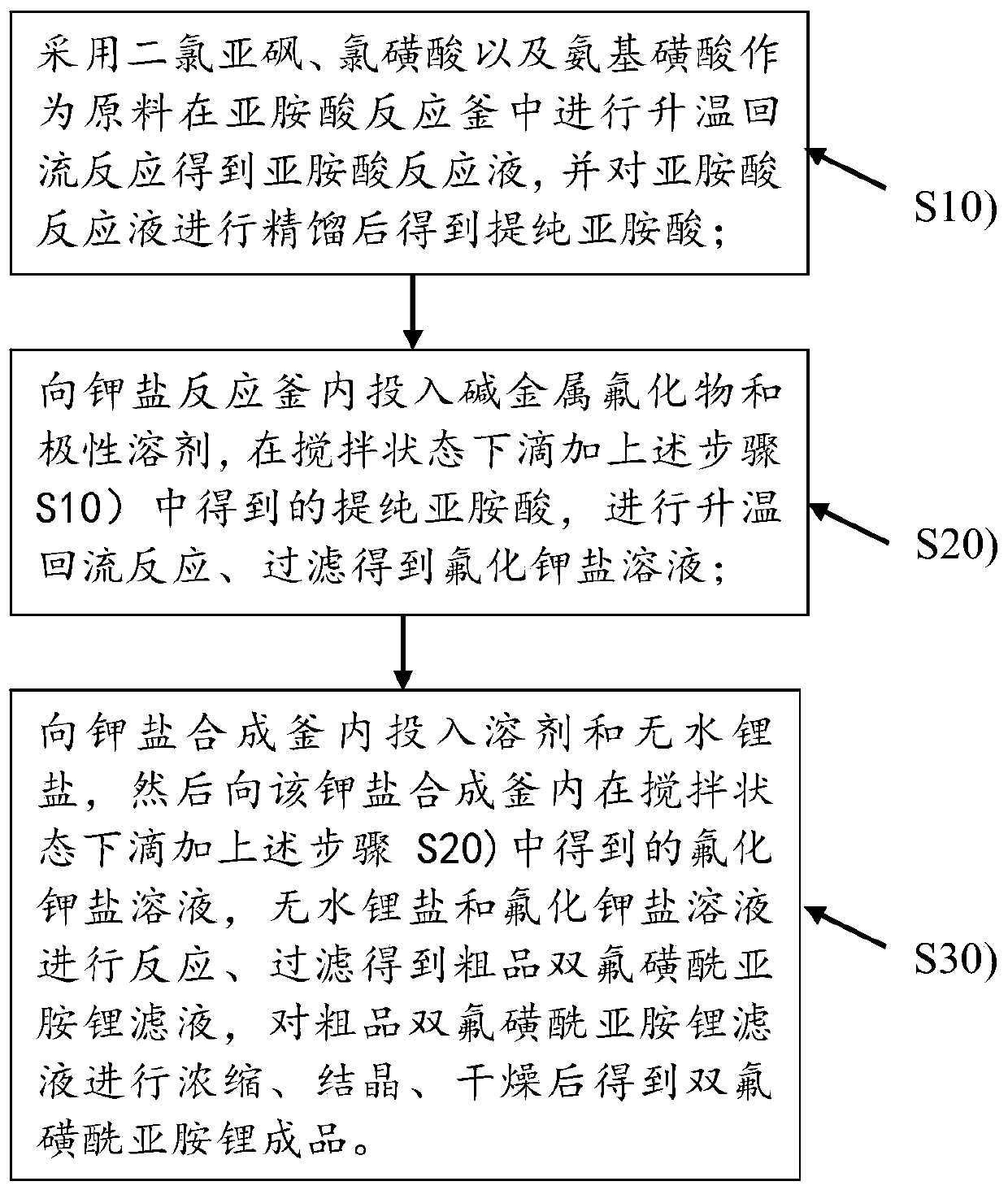

[0035] Embodiment 1: a kind of preparation method of lithium bisfluorosulfonyl imide comprises the following steps:

[0036] S10), using sulfamic acid, chlorosulfonic acid and thionyl chloride with a mass molar ratio of 1:1.2:2.5 as raw materials in an imidic acid reaction kettle to perform a temperature-intensive reflux reaction to obtain an imidic acid reaction solution, and the temperature-intensive reflux reaction The temperature is kept at 50-140°C, and the heat preservation reaction time is 48 hours; the heating reaction is stopped, and the generated HCL and SO 2 Exhaust gas is discharged into the exhaust gas absorption system, respectively for HCL, SO 2 After the tail gas is treated with water and alkali, the by-products hydrochloric acid and sodium sulfite are collected to obtain by-product hydrochloric acid and sodium sulfite, which meets the environmental protection emission requirements, and hydrochloric acid and sodium sulfite are obtained as by-products, which eff...

Embodiment 2

[0040] Embodiment 2: all the other technical solutions of this embodiment 2 are the same as embodiment 1, the difference is that in this embodiment 2, in step S10), the mass molar ratio of sulfamic acid, chlorosulfonic acid and thionyl chloride is 1:1.4:2.8; in step S20) and step S30), the polar solvent all adopts acetonitrile, and the molar ratio of potassium fluoride and imidic acid is 3:1; in step S30), anhydrous lithium chloride The mass molar ratio with acetonitrile is 1:7.5, and the secondary concentration process in Example 1 is replaced by a primary concentration process (disposable evaporation); after testing, the purity of the lithium bisfluorosulfonyl imide in this Example 2 The yield is 99.5%, wherein the free acid content is 80PPM, the moisture content is 50PPM, the chloride ion content is 3PPM, and the yield reaches 65.6%.

Embodiment 3

[0041] Embodiment 3: the remaining technical solutions of this embodiment 2 are the same as embodiment 1, the difference is that in this embodiment 2, in step S10), the mass molar ratio of sulfamic acid, chlorosulfonic acid and thionyl chloride is 1:1.2:3; in step S20), the molar ratio of potassium fluoride to imidic acid is 6:1. After testing, the purity of lithium bisfluorosulfonyl imide in Example 3 is 99.8%, wherein , the free acid content is 30PPM, the water content is 40PPM, the chloride ion content is 40PPM, and the yield reaches 62.5%.

[0042] This example creatively uses thionyl chloride, chlorosulfonic acid, and sulfamic acid as raw materials with low raw material cost and easy availability, and prepares imidic acid under the condition of elevated temperature and reflux reaction, and then uses the same low-cost raw material and easy-to-obtain Potassium fluoride as a raw material reacts with imidic acid to obtain potassium salt, and then reacts potassium fluoride sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com