Preparation method of low-temperature-resistant car urea solution

A vehicle urea, low temperature resistance technology, applied in the field of chemical technology, can solve the problems of limited selection range of modifiers, limited use, low crystallization point of urea solution, etc., to achieve large cost advantages, improve low temperature resistance, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

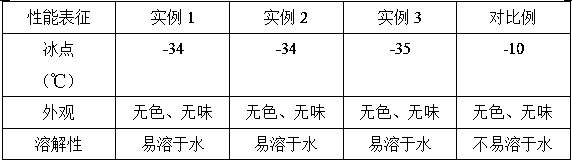

Examples

Embodiment Construction

[0022] Peel off the outer skin of the pomelo peel and collect the white floc, wash it with deionized water for 2 to 3 times, air-dry it naturally, put it into a pulverizer and grind it, pass through a 20-mesh sieve to get the pretreated pomelo peel, take 300-500g for pretreatment Put the pomelo peel into the steam explosion tank, and feed 1.5-2.5MPa water vapor with a temperature of 210-240°C into the steam explosion tank, keep the pressure for 3-4 minutes, open the valve of the steam explosion tank instantly, release the pressure to normal pressure, and then filter To obtain the filter residue, wash the filter residue with deionized water at a temperature of 80-85°C for 2-3 times, place it in a drying oven, and dry it at 60-80°C until it reaches a constant weight, and then obtain steam explosion-treated pomelo peel, and take 100-120g of soybean protein Powder, 25-30g ammonium alginate, 200-300g steam explosion treated pomelo peel, add 5-6L deionized water, stir at 300-400r / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com