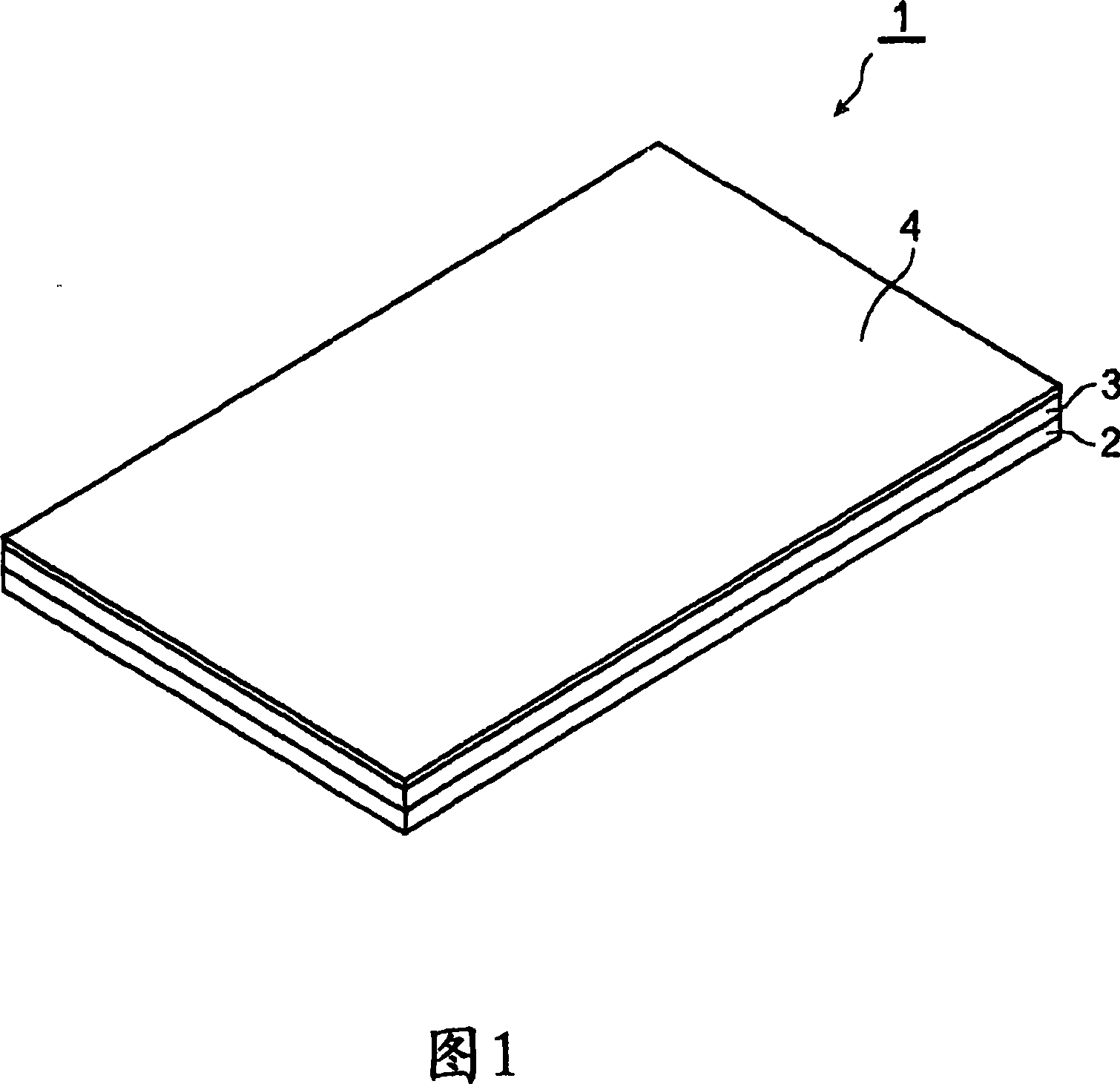

Adhesive skin patch

A patch and additive technology, applied in the direction of anti-inflammatory agents, non-central analgesics, skin care preparations, etc., can solve the problems of low melting point of gelatin, liquid dripping, and limited selection range of compounding substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Add 0.5 parts by mass of "UP-37K" (trade name, manufactured by Ina Food Industry Co., Ltd.) as soluble agar to warm water at 70 to 80°C, gel strength: 700 g / cm 2 ), 0.5 parts by mass of synthetic aluminum silicate, 0.5 parts by mass of polyethylene glycol monostearate as a surfactant, and 3.0 parts by mass of polyvinyl alcohol were stirred at 70° C. to dissolve the raw materials. Then, move the total amount of this solution to a cooled stirrer, and then add 0.5 parts by mass of magnesium aluminosilicate metasilicate, 0.3 parts by mass of sodium edetate, and 1.0 parts by mass of L-mint A mixture of alcohol, 5.0 parts by mass of partially neutralized polyacrylic acid, and 30.0 parts by mass of glycerin, and further added purified water so that the total amount becomes 100 parts by mass. Cool the mixture at about 10°C and stir to prepare the adhesive base. When the solution of the soluble agar in the process of production was transferred to a cooled stirrer, the gelation ...

Embodiment 2-5

[0095] When preparing an adhesive base, except for the component composition shown in Table 1, it carried out similarly to Example 1, and prepared an adhesive base. When the solution of the soluble agar in the process of production was transferred to a cooled stirrer, the gelation state of the agar was observed, and it was considered that there was no gelation. Using the obtained adhesive base, it carried out similarly to Example 1, and obtained the patch. In addition, the same evaluation as Example 1 was performed about the obtained patch. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com