Arc ion plating-magnetron sputtering composite deposition high-temperature wear-resisting antifriction AlTiN nano multi-layer coating and preparing method and application thereof

A magnetron sputtering composite and arc ion plating technology, applied in ion implantation plating, coating, sputtering plating, etc., to achieve strong operability, simple preparation method, improved friction and wear resistance and thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

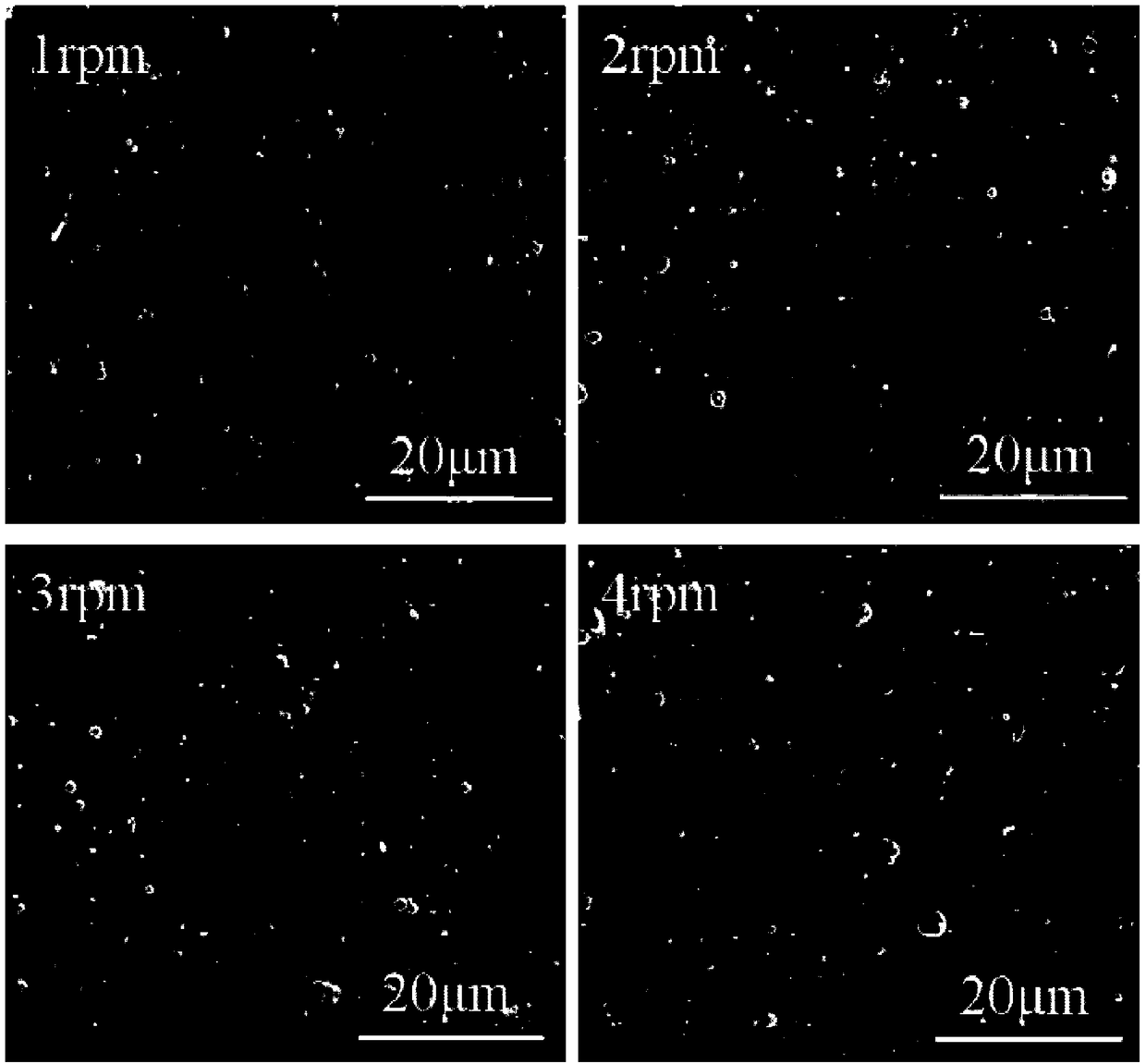

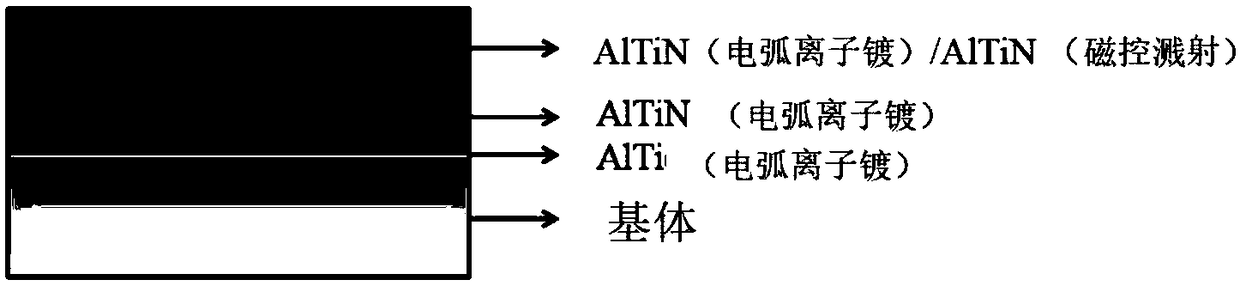

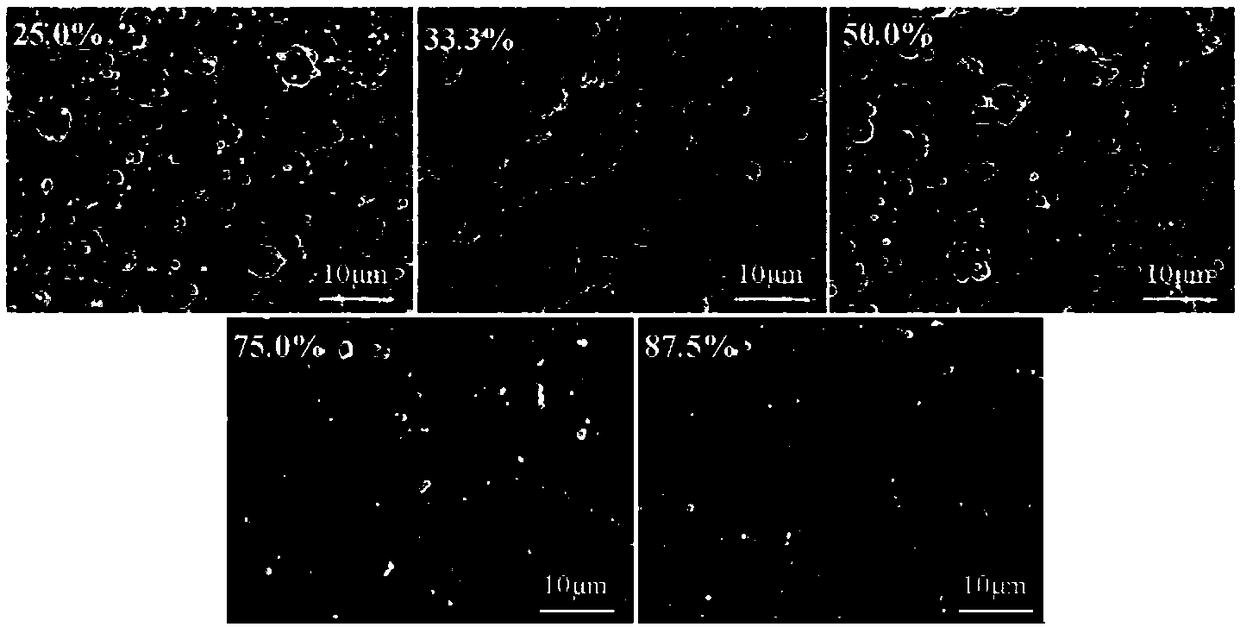

[0032] An arc ion plating-magnetron sputtering composite deposition high temperature wear-resistant anti-friction AlTiN nano multi-layer coating, the nano multi-layer coating includes a hard alloy substrate, a metal AlTi bonding layer, an AlTiN transition layer and an AlTiN coating from bottom to top Functional layer; AlTiN functional layer is deposited alternately by arc ion plating AlTiN intermediate layer and magnetron sputtering AlTiN intermediate layer with a modulation ratio of 1:1 to 10:1, and the modulation period range is 5 to 25nm; metal AlTi bonding layer The atomic percentage content of each element in the film is: Al: 50-70 at.%, Ti: 30-50 at. %; the atomic percentage content of each element in the AlTiN transition layer, arc ion plating AlTiN intermediate layer and magnetron sputtering AlTiN intermediate layer All are: Al: 20-28 at.%, Ti: 18-22 at.%, N: 45-55 at.%. The preparation method follows the steps below:

[0033] Polish the cemented carbide substrate, ul...

Embodiment 2

[0037] An arc ion plating-magnetron sputtering composite deposition high temperature wear-resistant anti-friction AlTiN nano multi-layer coating, the nano multi-layer coating includes a hard alloy substrate, a metal AlTi bonding layer, an AlTiN transition layer and an AlTiN coating from bottom to top Functional layer; AlTiN functional layer is deposited alternately by arc ion plating AlTiN intermediate layer and magnetron sputtering AlTiN intermediate layer with a modulation ratio of 1:1 to 10:1, and the modulation period range is 5 to 25nm; metal AlTi bonding layer The atomic percentage content of each element in the film is: Al: 50-70 at.%, Ti: 30-50 at. %; the atomic percentage content of each element in the AlTiN transition layer, arc ion plating AlTiN intermediate layer and magnetron sputtering AlTiN intermediate layer All are: Al: 20-28 at.%, Ti: 18-22 at.%, N: 45-55 at.%. The preparation method follows the steps below:

[0038] Polish the cemented carbide, ultrasonical...

Embodiment 3

[0042] An arc ion plating-magnetron sputtering composite deposition high temperature wear-resistant anti-friction AlTiN nano multi-layer coating, the nano multi-layer coating includes a hard alloy substrate, a metal AlTi bonding layer, an AlTiN transition layer and an AlTiN coating from bottom to top Functional layer; AlTiN functional layer is deposited alternately by arc ion plating AlTiN intermediate layer and magnetron sputtering AlTiN intermediate layer with a modulation ratio of 1:1 to 10:1, and the modulation period range is 5 to 25nm; metal AlTi bonding layer The atomic percentage content of each element in the film is: Al: 50-70 at.%, Ti: 30-50 at. %; the atomic percentage content of each element in the AlTiN transition layer, arc ion plating AlTiN intermediate layer and magnetron sputtering AlTiN intermediate layer All are: Al: 20-28 at.%, Ti: 18-22 at.%, N: 45-55 at.%. The preparation method follows the steps below:

[0043] Polish the cemented carbide, ultrasonical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com