Method for lifting crystal growth by induction heating in reducing atmosphere

A technology for induction heating and growing crystals, which is applied in the directions of self-melt pulling method, single crystal growth, crystal growth, etc. It can solve the problems of high cost, high equipment requirements, and high maintenance costs, and achieve cost reduction, low price, and general use strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

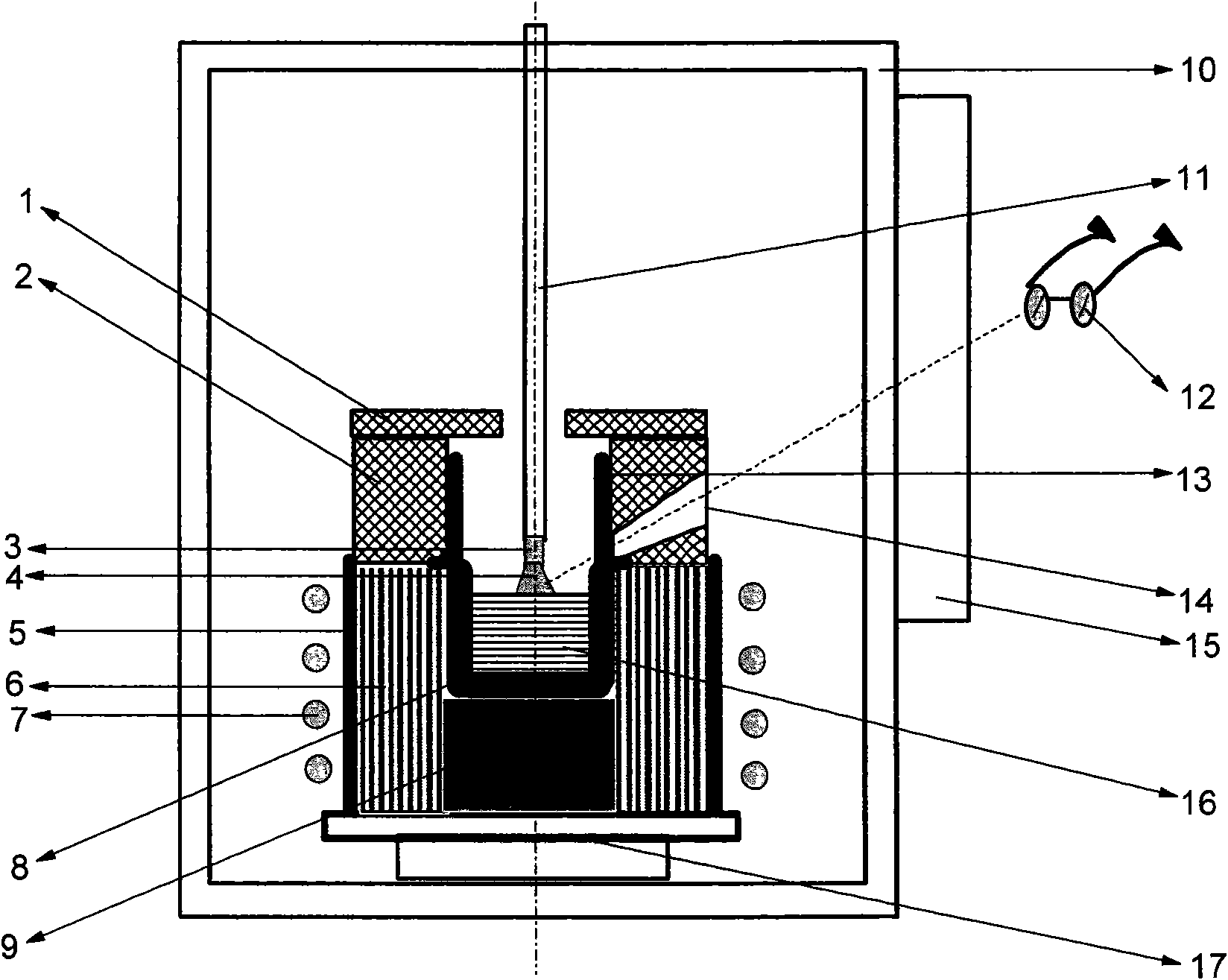

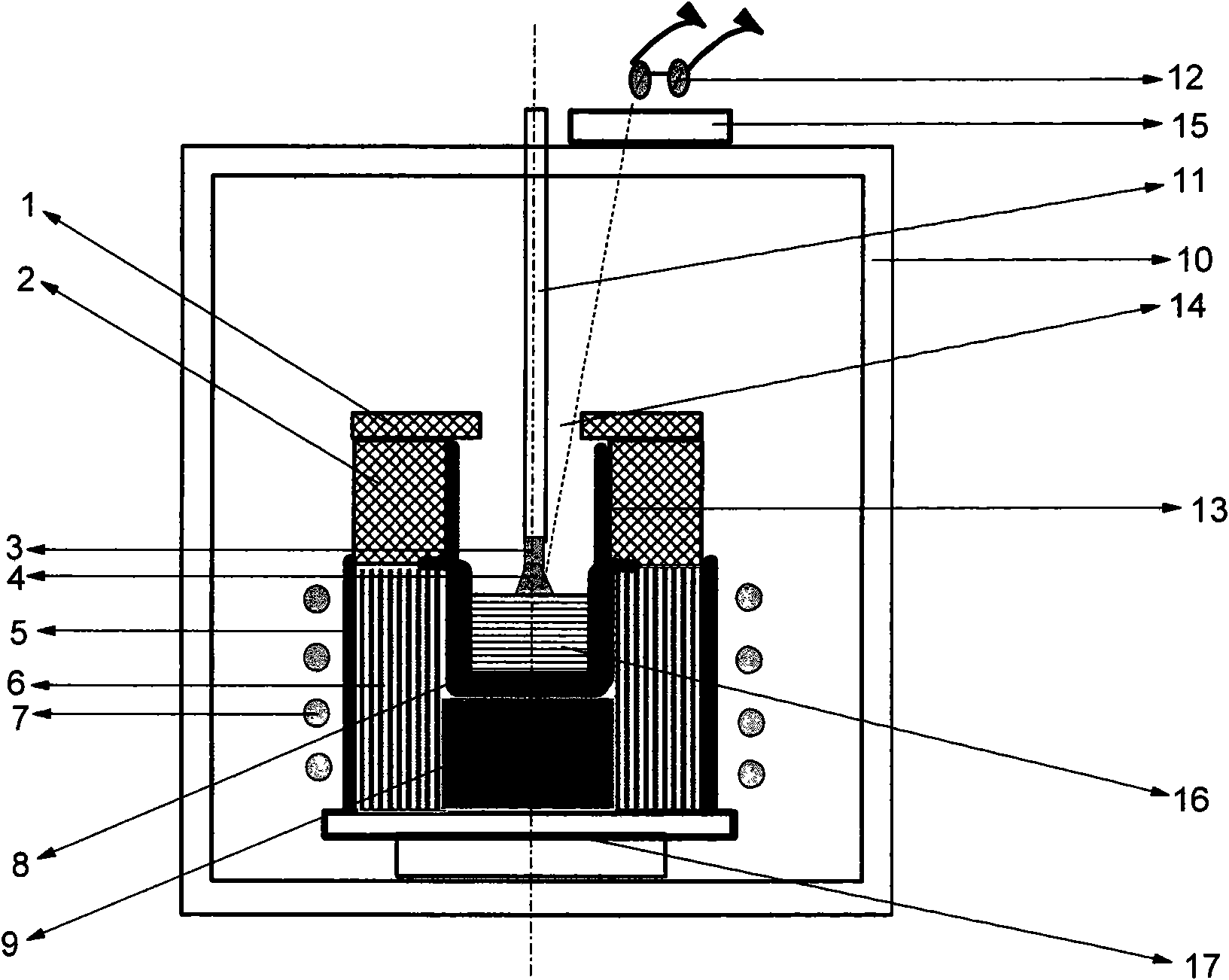

[0042] Embodiment 1: use molybdenum crucible, graphite felt grows sapphire (Al 2 o 3 ) crystal

[0043] First, put the molybdenum crucible 8 on the hard graphite felt 9, then wrap the multi-layer soft graphite felt 6 outside the hard graphite felt 9 and the crucible 8, then put it in the quartz barrel 5, and put it into the pulling crystal furnace as a whole In the induction coil 7 of the furnace, place it on the tray 17 at the bottom of the furnace, place the Al 2 o 3 Put the raw materials into the crucible 8, place a hard graphite felt insulation cover 2 above the molybdenum crucible 8, cover the hard graphite felt insulation cover 1, close the furnace door, and vacuumize. After the vacuum degree reaches better than 20 Pa, fill the Argon protective atmosphere, using the common process of growing sapphire by pulling method for crystal growth. Anneal the grown sapphire crystal in a muffle furnace at 1600°C for 2 hours in an air atmosphere to eliminate the oxygen ion vacanc...

Embodiment 2

[0044] Embodiment 2: use molybdenum crucible, graphite felt grows titanium sapphire (Al 2 o 3 : Ti 3+ ) crystal

[0045] First, put the molybdenum crucible 8 on the hard graphite felt 9, then wrap the multi-layer soft graphite felt 6 outside the hard graphite felt 9 and the crucible 8, then put it in the quartz barrel 5, and put it into the pulling crystal furnace as a whole In the induction coil 7 of the furnace, place it on the tray 17 at the bottom of the furnace, place the Al 2 o 3 Put the Ti raw material into the molybdenum crucible 8, place a hard graphite felt insulation cover 2 on the top of the molybdenum crucible 8, cover the hard graphite felt insulation cover 1, close the furnace door, vacuumize, and treat that the vacuum degree is better than 20 Pa. , filled with argon protective atmosphere, and the crystal growth is carried out by the common process of growing titanium sapphire by the pulling method. After the growth, the titanium sapphire crystal is first a...

Embodiment 3

[0046] Embodiment 3: use tungsten crucible, graphite felt, zirconia insulation cover growth neodymium-doped yttrium aluminum garnet (Nd:Y 3 al 5 o 12 ) crystal

[0047]First, put the tungsten crucible 8 on the hard graphite felt 9, then wrap the multi-layer soft graphite felt 6 outside the hard graphite felt 9 and the tungsten crucible 8, then put it in the quartz barrel 5, and put it into the pulling crystal furnace as a whole In the induction coil 7 inside, place on the tray 17 at the bottom of the furnace, put Nd:Y 3 Al 5 o 12 Put the raw materials into the tungsten crucible 8, then place the zirconia brick insulation cover 2 on the top of the tungsten crucible 8, cover the zirconia insulation cover 1, close the furnace door, vacuumize, fill in the nitrogen protective atmosphere, and grow by pulling method Yttrium aluminum garnet crystal growth is performed by a common process. The yttrium aluminum garnet crystal after the growth is first annealed in the muffle furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com