Multifunctional gas protection atmosphere case for laser cladding formation

A gas shielding and laser cladding technology, used in laser welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

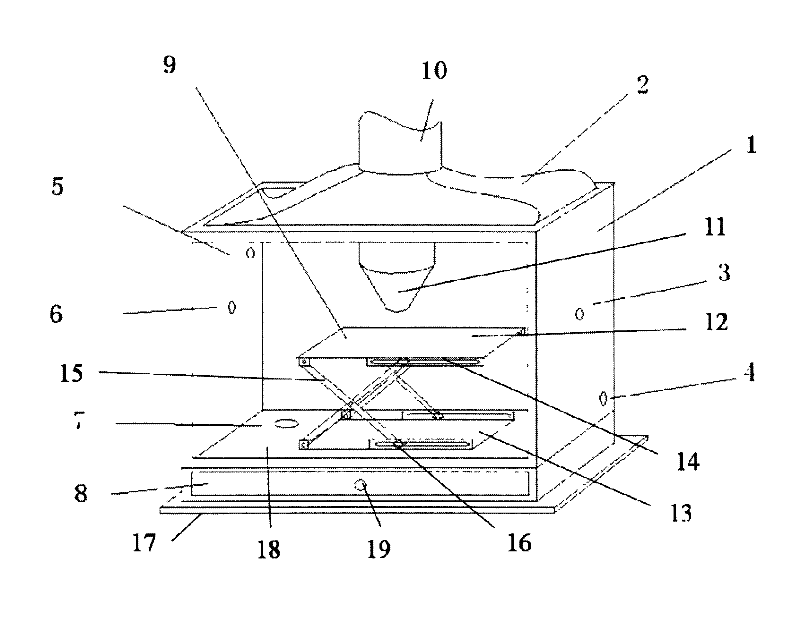

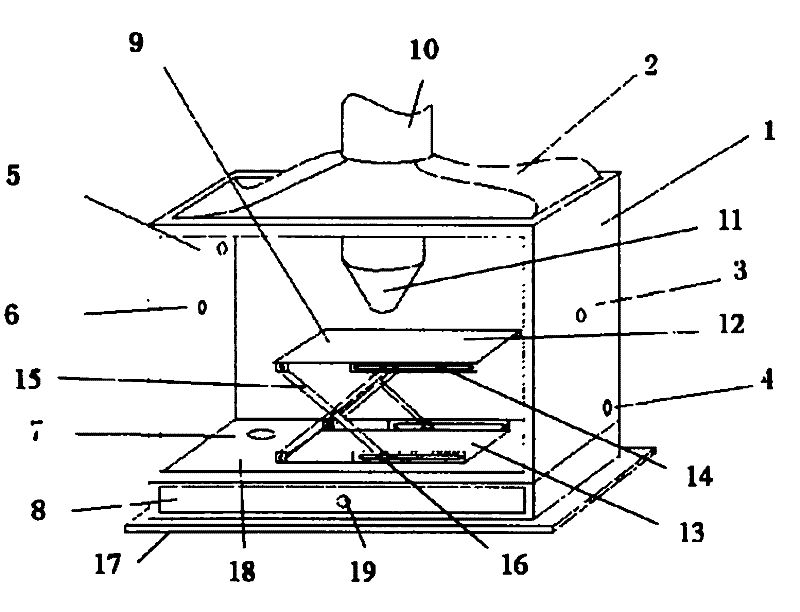

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0020] like figure 1 Shown is a schematic diagram of the structure of the multifunctional inert gas protective atmosphere box. The interior of the box 1 is divided into two parts: an upper processing chamber and a lower powder collection chamber by a middle partition 18 . Exhaust holes 5 and temperature monitoring holes 6 are arranged on the left side panel of the box body 1, and air inlet holes 4 and air pressure monitoring holes 3 in the box are arranged on the right side panel. The opening positions of each hole can be determined according to the setting of the experimental equipment, and are not limited to the above positions. The upper cover of the box body 1 is a sealed soft top 2 that allows the laser head 10 and the coaxial powder feeding head 11 to pass through. There is an opening in the middle of the sealed soft top 2. The opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com