Method for performing steam explosion of wood fiber raw material, directional enzymatic dissociation and alcoholic fermentation

A lignocellulosic raw material, directional enzymatic hydrolysis technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of complex process control, high wind consumption, low tolerance, etc., and achieve simple process, Improve economic efficiency and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] After the straw and grass raw materials are air-dried, they are cut into 3-5cm lengths by a rotary cutting device and stored for later use.

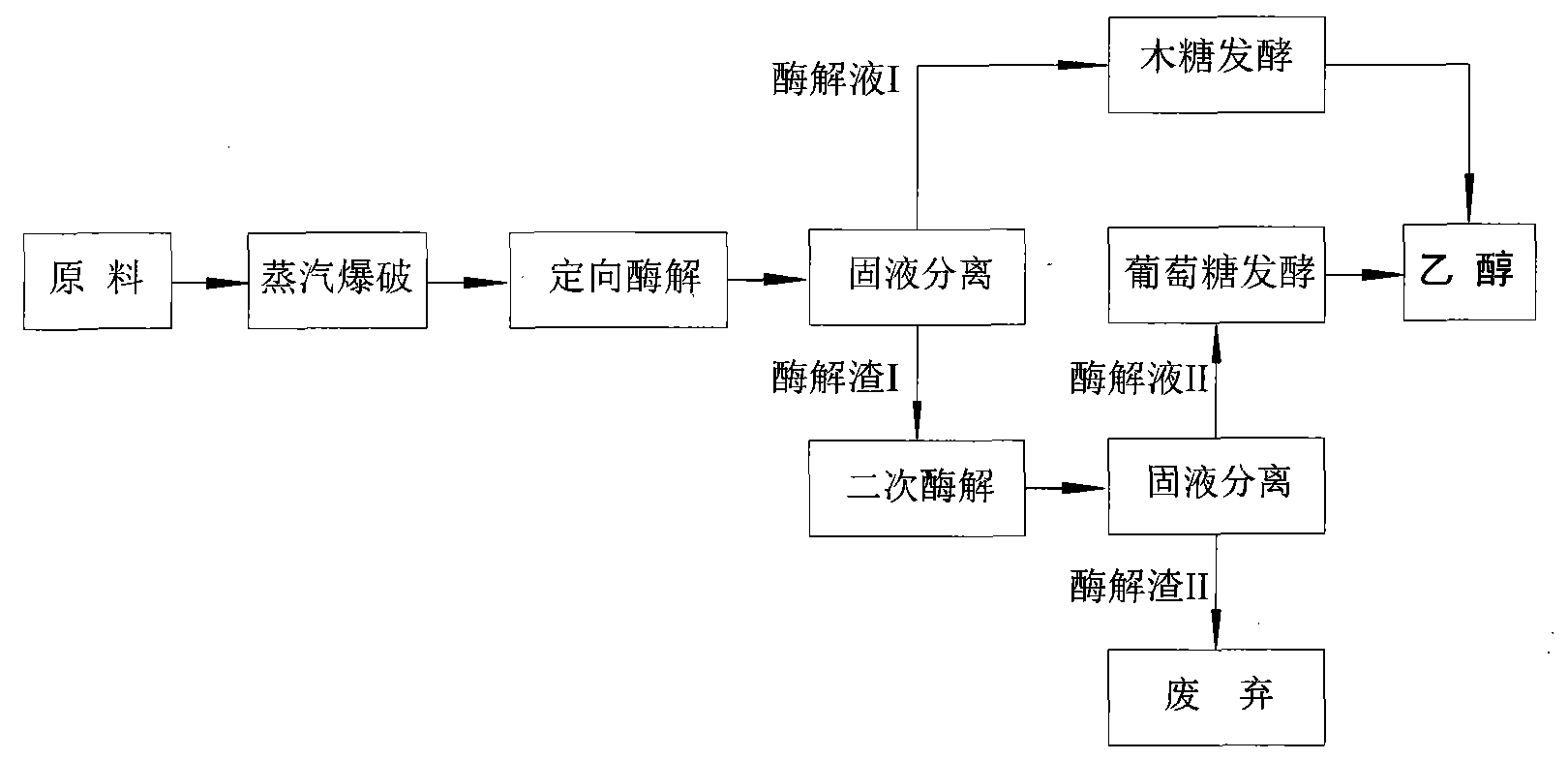

[0026] The cut straw or grass raw materials are added to the intermittent automatic steam explosion device, and the natural accumulation method is used for filling to ensure the uniformity of steam heating, and the volume filling coefficient is controlled to be 65-75%. After sealing, steam is introduced to directly heat the material to a temperature of 195-205°C. After using steam to keep warm for 60-180 seconds, the automatic discharge valve is quickly opened by the automatic control system to blast and discharge to obtain slurry. The dry weight yield of the slurry reaches more than 80% of the raw material, among which the yield of glucose group is higher than 85%, accounting for 43.0-45.0% of the dry weight of the slurry, and the yield of xylose group reaches more than 60%, accounting for more than 85% of the dry weight of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com