Zero grain consuming full liquid state method for producing vinegar with solid state fermentation flavor

A solid-state fermentation and liquid-state technology, which is applied in the field of condiment manufacturing, can solve the problems of low processing utilization rate, monotonous taste of vinegar, and high production cost, and achieve remarkable economic and environmental benefits, natural and mellow fragrance, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

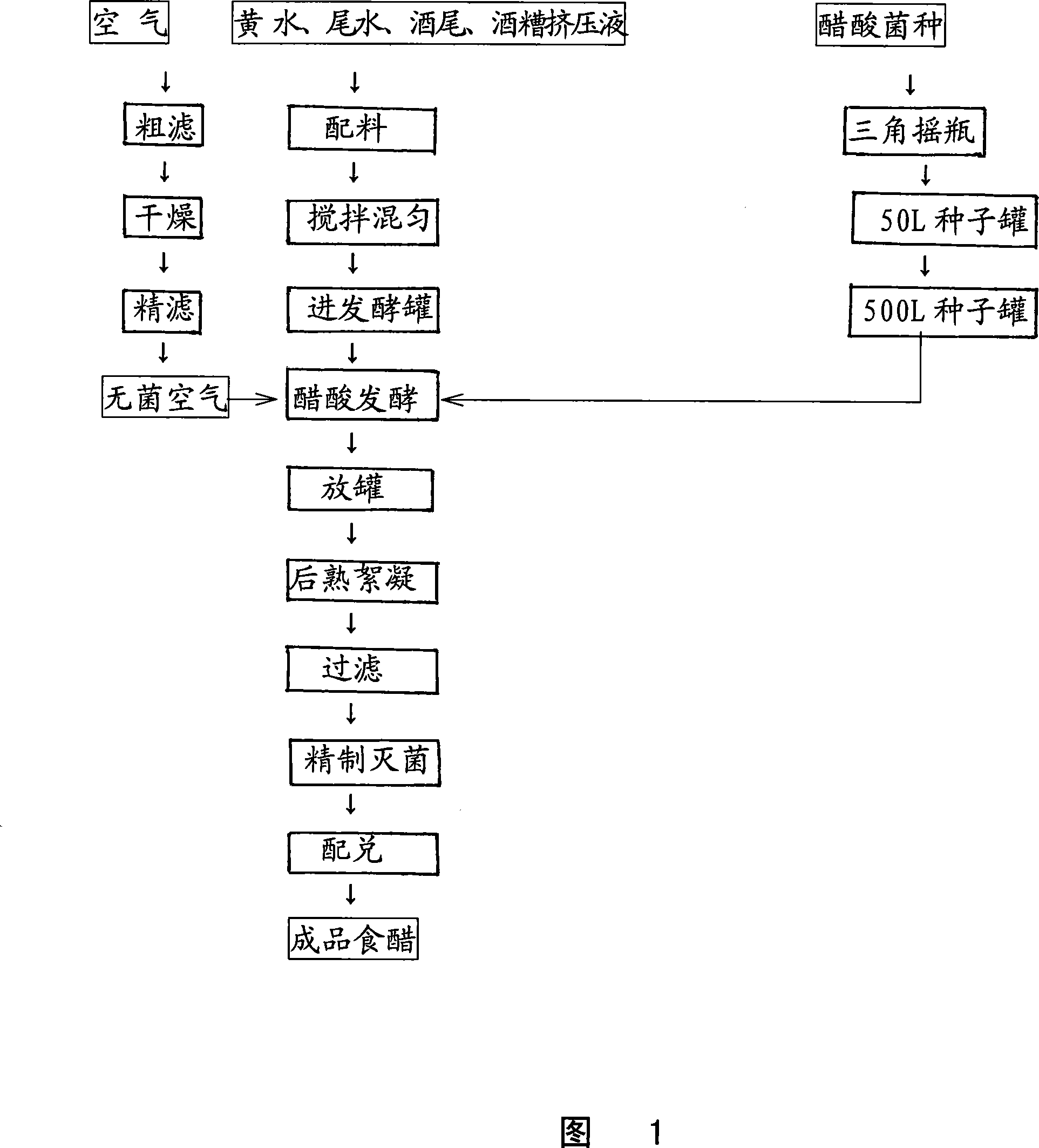

Method used

Image

Examples

Embodiment 1

[0036] Main raw and auxiliary materials:

[0037] Fresh yellow water: Fresh liquid from Sichuan Tuopai Liquor Co., Ltd. liquor with normal solid-state fermentation, total acid 4.77g / 100ml, alcohol content 5.5V / V%.

[0038] Squeeze liquid of distiller's grains: Squeeze liquid of distiller's grains from Sichuan Tuopai Liquor Co., Ltd. with normal liquor solid-state fermentation, total acid 2.65g / 100ml.

[0039] Wine tail: Distilled liquor from Sichuan Tuopai Liquor Co., Ltd., with total acid 0.50g / 100ml and alcohol content 6.3V / V%.

[0040] Tail water: Distilled liquid from Sichuan Tuopai Liquor Co., Ltd., with total acid 2.10g / 100ml and alcohol content of 0.4V / V%.

[0041] Acetic acid bacteria liquid: The acetic acid bacteria liquid is prepared by the preparation process of acetic acid bacteria No. 1.41 through inclined plane culture → triangular shake flask culture → primary seed tank → secondary seed tank.

[0042] Fried Beige: The filtrate made according to the traditional prepa...

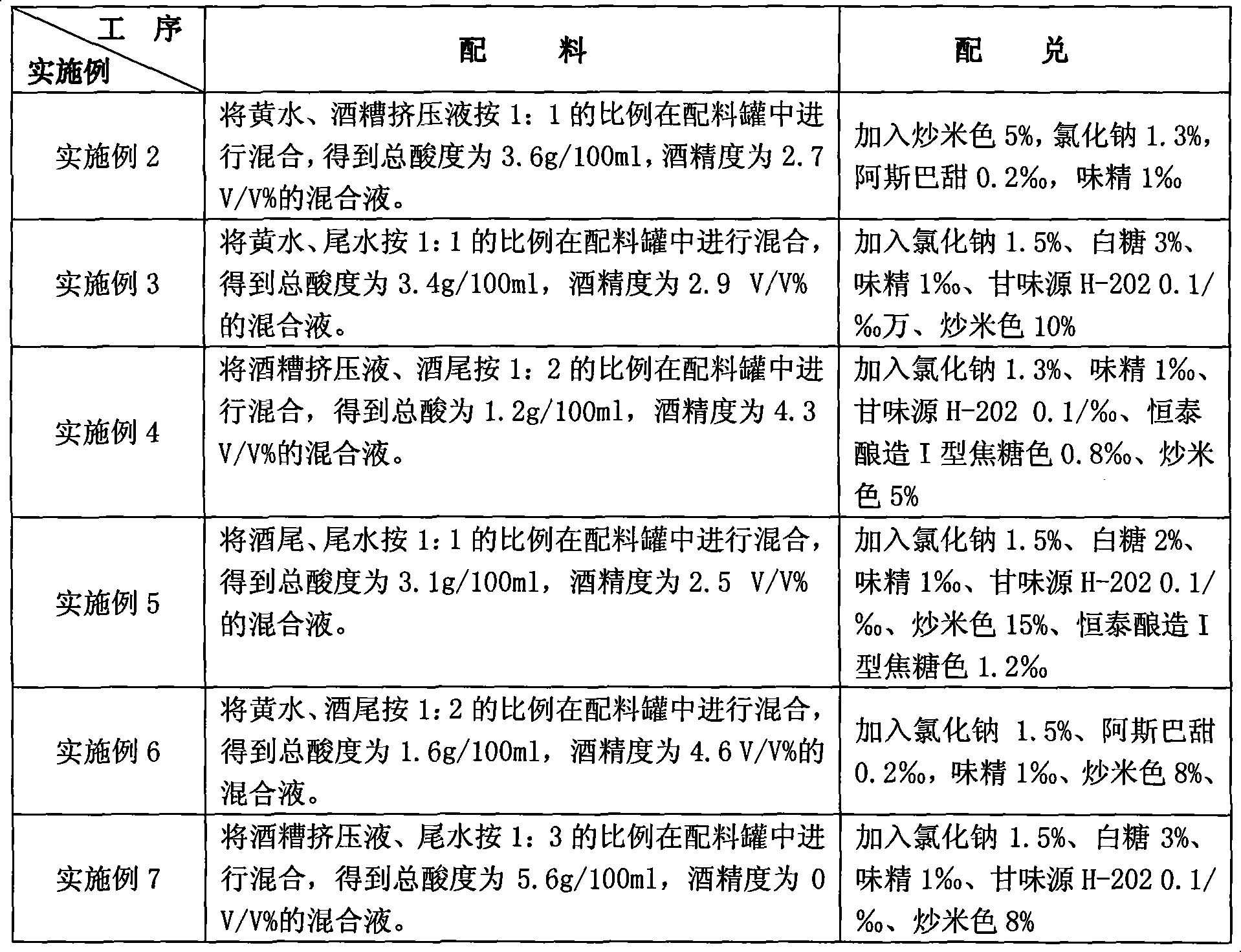

Embodiment 2-7

[0050] Main raw and auxiliary materials: Examples 2-5 are the same as Example 1.

Embodiment 6-7

[0051] In Examples 6-7:

[0052] Fresh yellow water: Fresh liquid from Sichuan Tuopai Liquor Co., Ltd. liquor with normal solid-state fermentation, total acid 2.9g / 100ml, alcohol content 4.0V / V%.

[0053] Squeeze liquid of distiller's grains: Squeeze liquid of distiller's grains from Sichuan Tuopai Liquor Co., Ltd. with normal liquor solid-state fermentation, total acid 3.6g / 100ml.

[0054] Wine tail: Distilled liquor from Sichuan Tuopai Liquor Co., Ltd., total acid 1.0g / 100ml, alcohol content 5.0V / V%.

[0055] Tail water: Distilled liquid from Sichuan Tuopai Liquor Co., Ltd., total acid 6.3g / 100ml.

[0056] The fried rice and acetic acid bacteria liquid are the same as in Example 1.

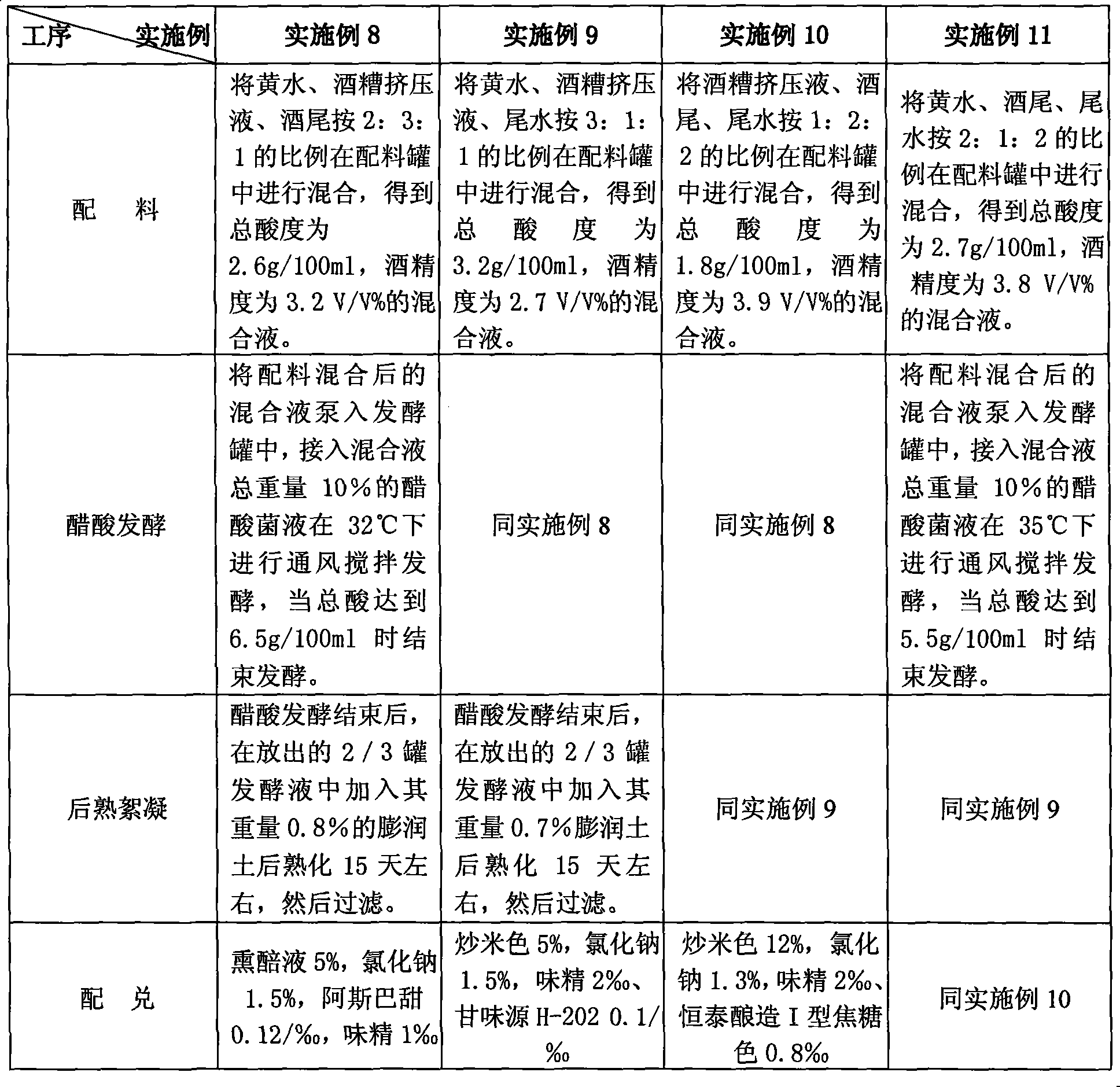

[0057] crafting process:

[0058] The processes of acetic acid fermentation, post-cooking flocculation, and purification and sterilization are the same as in Example 1;

[0059] The contents of the ingredients and blending process are listed in the following table:

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com