Treating technology for chemical RO concentrated water

A concentrated water and process technology, which is applied in the field of aromatic hydrocarbon chemical wastewater RO concentrated wastewater removal and COD degradation up-to-standard discharge process, can solve the problems of effluent not meeting direct discharge requirements, high treatment process costs, and unstable effluent quality. , to ensure that the effluent quality meets the standards and stability, enhance the adsorption and degradation effect, and achieve the effect of outstanding treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

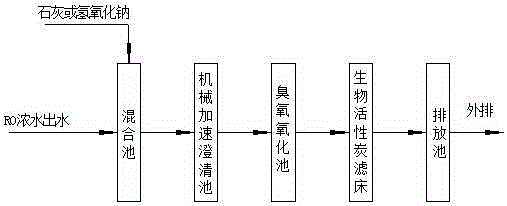

[0032] Such as figure 1 As shown, the treatment process described in this embodiment includes the following steps:

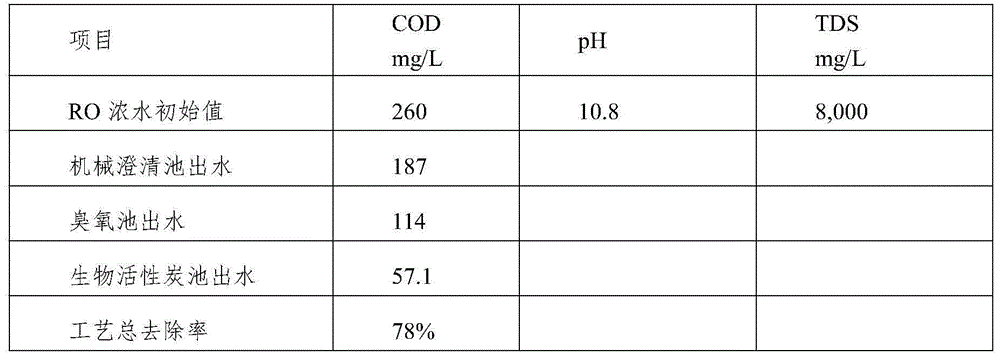

[0033] (1) Add lime emulsion to the RO concentrated water in the mixing tank, adjust the pH value of the RO concentrated water to 11, soften the RO concentrated water and make some metal ions in the RO concentrated water flocculate and precipitate; The indicators are: COD: 220mg / L, pH10.5, TDS6,000, so that calcium and magnesium ions and some metal ions (including reducing metals) in RO concentrated water can form carbonate or M(OH)x under alkaline conditions Insoluble salts and other insoluble salts and complex ion flocs precipitate.

[0034](2) Pass the softened RO concentrated water into a mechanically accelerated clarifier for sedimentation to remove flocs, suspended matter and large particles in the water; the motor speed of the mechanically accelerated clarifier is 400 to 800r / min, and the impeller line The speed is usually controlled at 0.5-2.5m / s (to a...

Embodiment 2

[0041] Compared with Example 1, the only differences are: the RO concentrated water is added with lime emulsion to adjust the pH value to 11.2; the dosage of ozone is 67mg / L, the reaction time is 0.75h; the filtration rate of the biological activated carbon filter bed is 10m / h.

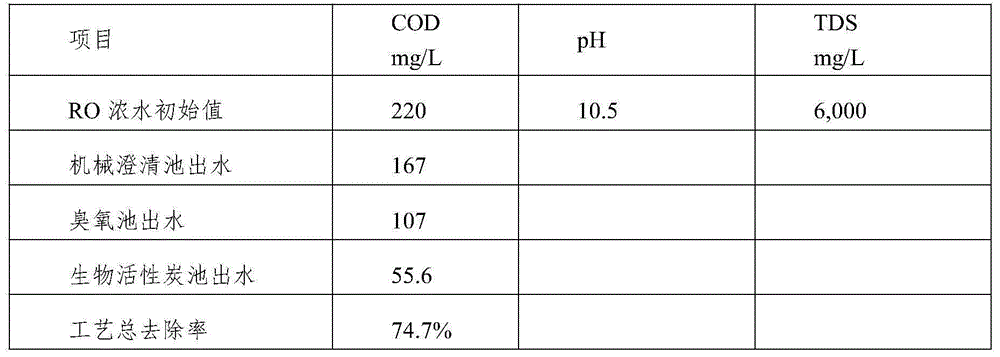

[0042] The COD degradation of RO concentrated water at each stage after the RO concentrated water is treated by the process described in this example is shown in Table 2:

[0043] Table 2

[0044]

Embodiment 3

[0046] Compared with Example 1, the only differences are: the RO concentrated water is added with lime emulsion to adjust the pH value to 11.5; the dosage of ozone is 46mg / L, the reaction time is 0.75h; the filtration rate of the biological activated carbon filter bed is 14m / h. The actual data of the composition of RO concentrated water at each stage after the RO concentrated water is treated by the process described in this embodiment is shown in Table 3:

[0047] table 3

[0048]

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com