Venous industrial park system taking waste incineration power plant as core

A technology of waste incineration and waste incinerator, which is applied to the methods of incinerating corpses, incinerators, and combustion methods. Effect of land area and investment cost, reduction of operation cost and improvement of management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the example of the present invention is described in detail:

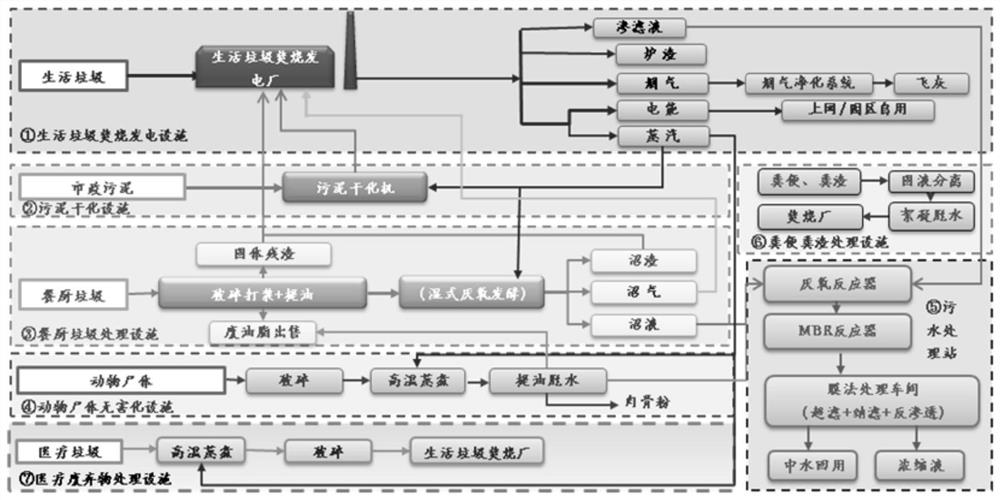

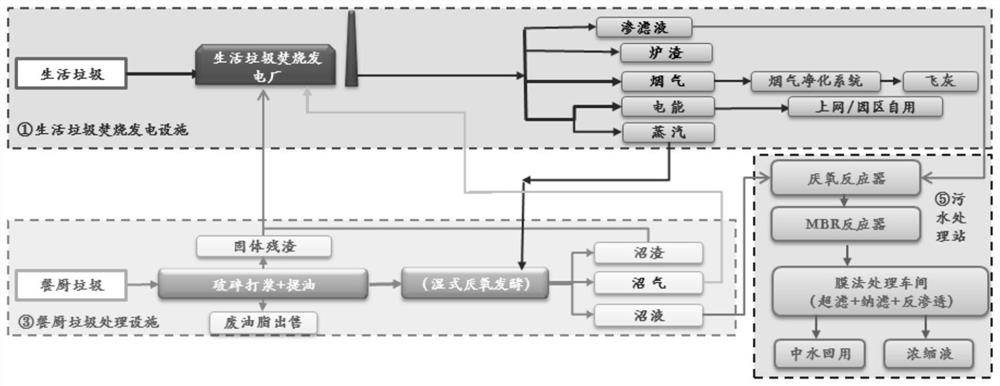

[0020] like figure 1 As shown in the drawings, the description includes: ① domestic waste incineration power plant, ② sludge drying facilities, ③ food waste treatment facilities, ④ animal carcasses harmless disposal facilities, ⑤ sewage treatment station, ⑥ excrement and dregs treatment facilities , ⑦ medical waste treatment facilities.

[0021] A venous industrial park system with a waste incineration power plant as the core. The specific implementation of the invention is as follows:

[0022] The venous industrial park is centered on the domestic waste incineration power plant. The leachate produced by the waste incineration power plant ① enters the park’s sewage treatment station ⑤ for disposal; the slag is comprehensively utilized as building materials; After being stabilized, the fly ash produced in the plant meets the relevant standards and can be sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com