Tail gas purification treatment system of cremation machine

A technology of exhaust gas purification and treatment system, applied in the field of exhaust gas purification and treatment, can solve problems such as unsatisfactory flue gas treatment effect and environmental pollution, and achieve the effects of good environmental protection effect, high dust removal efficiency and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

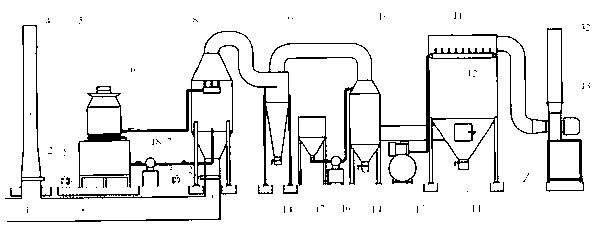

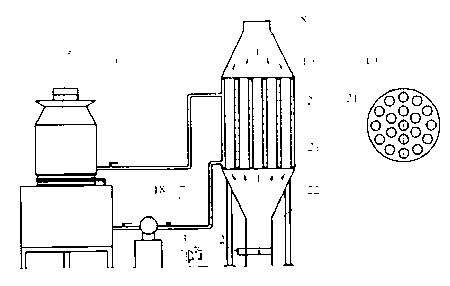

[0014] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the present invention relates to a cremation machine tail gas purification treatment system, which is equipped with an emergency smoke exhaust system, a flue gas cooling system, a spiral dust collector, an acid removal system, and a bag dust removal system. It is characterized in that: the emergency smoke exhaust system A flue 1 is provided, and one end of the flue 1 leads to the emergency chimney 4 and the quenching tower 8 respectively, and the bottoms of the emergency chimney 4 and the quenching tower 8 are equipped with flue dampers 2, and both flue dampers 2 are equipped with The power mechanism 3 controls its opening and closing; the flue gas cooling system is provided with a quenching tower 8, the lower part of the quenching tower 8 is connected to one end of the water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com