Harmless treatment device of carcasses of animals died of diseases for livestock farm

A technology for harmless treatment of dead animals, applied in the methods of incinerating corpses, incinerators, burning methods, etc., can solve the problems of easy spread of pathogens, waste of resources, high processing costs, etc., to avoid the spread of bacteria and viruses and The effects of dissemination, efficiency improvement, and safety efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

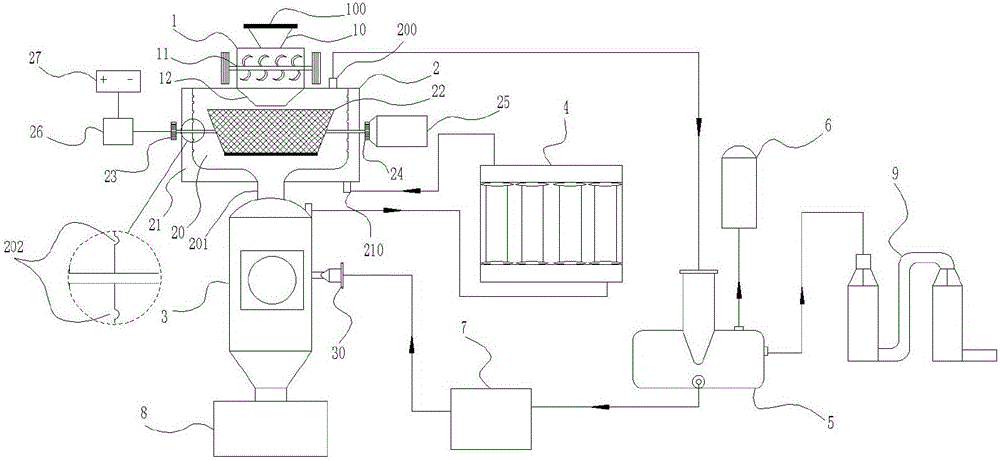

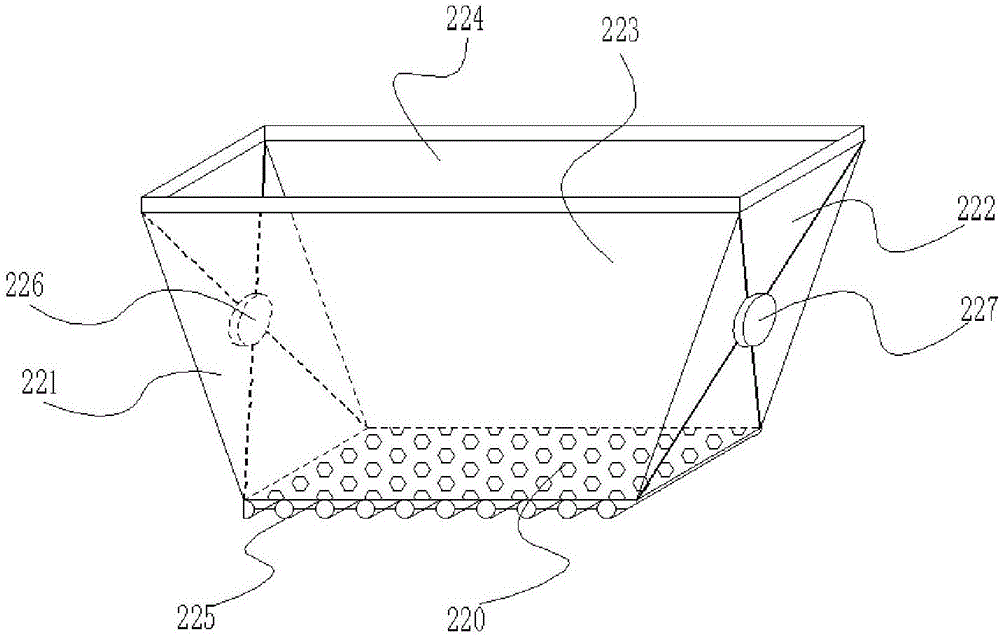

[0025] Such as figure 1 As shown, a harmless treatment device for dead and sick animal carcasses in a livestock farm mainly includes a crusher 1, a high-voltage electric carbonization chamber 2, an incinerator 3, a dust collector 4, an oil and gas separation and recovery device 5, a gas collecting box 6, a collector The fuel tank 7, the bone meal collection box 8, and the incineration tail gas purification device 9. The top of the crusher 1 is provided with a feed port 10, and a sealing cover 100 is also provided above the feed port 10 to prevent smoke from escaping. The inside of the crusher 1 is provided with a crushing mechanism 11, and the bottom of the crusher 1 is provided with a discharge port 12, which is located above the inside of the high-voltage electric carbonization chamber 2. The high-voltage electric carbonization chamber 2 includes an inner chamber 20 and equipment. The flue 21 on the left and right sides and the bottom of the inner chamber 20 is provided with 1...

Embodiment 2

[0033] The difference between this embodiment and embodiment 1 is that the working method of this embodiment includes the following steps:

[0034] S1: The first batch of crushing, put the dead animal carcasses into the crusher 1 through the feed port 10, use the crushing mechanism 11 to crush them into meat pieces, and transport the 50Kg meat pieces to the high-pressure grid 22 through the discharge port 12 Inside;

[0035] S2: After the crushing is completed, the feed port 10 is sealed by the sealing cover 100 to ensure that the high-voltage electric carbonization chamber 2 has a relatively sealed structure. Turn on the power supply 27 and apply a voltage of 52KV to the high-voltage grid 22 for 20 minutes. Carry out carbonization treatment, the generated oil and gas enter the oil and gas separation and recovery device 5 through the oil and gas outlet 200, and the separated oil and gas are stored in the gas collecting tank 6 and the oil collecting tank 7, respectively, and the rem...

Embodiment 3

[0039] The difference between this embodiment and embodiment 1 is that the working method of this embodiment includes the following steps:

[0040] S1: The first batch of crushing, put the dead animal carcasses into the crusher 1 through the feed port 10, use the crushing mechanism 11 to crush them into meat pieces, and transport 100Kg meat pieces to the high-pressure grid 22 through the discharge port 12 Inside;

[0041] S2: After the crushing is completed, the feed port 10 is sealed by the sealing cover 100 to ensure that the high-voltage electric carbonization chamber 2 has a relatively sealed structure, the power supply 27 is turned on, and the 100KV voltage is applied to the high-voltage grid 22 for 30 minutes. Carry out carbonization treatment, the generated oil and gas enter the oil and gas separation and recovery device 5 through the oil and gas outlet 200, and the separated oil and gas are stored in the gas collecting tank 6 and the oil collecting tank 7, respectively, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com