Purification treatment device for incineration flue gas

A treatment device and flue gas purification technology, which are applied to combined devices, methods of incinerating corpses, chemical instruments and methods, etc., can solve the problem of large total amount, no removal of acid gas pollutants, and inability to effectively remove dioxin-like organic pollution to ensure the quenching effect, comprehensive and more thorough purification, and prolong the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

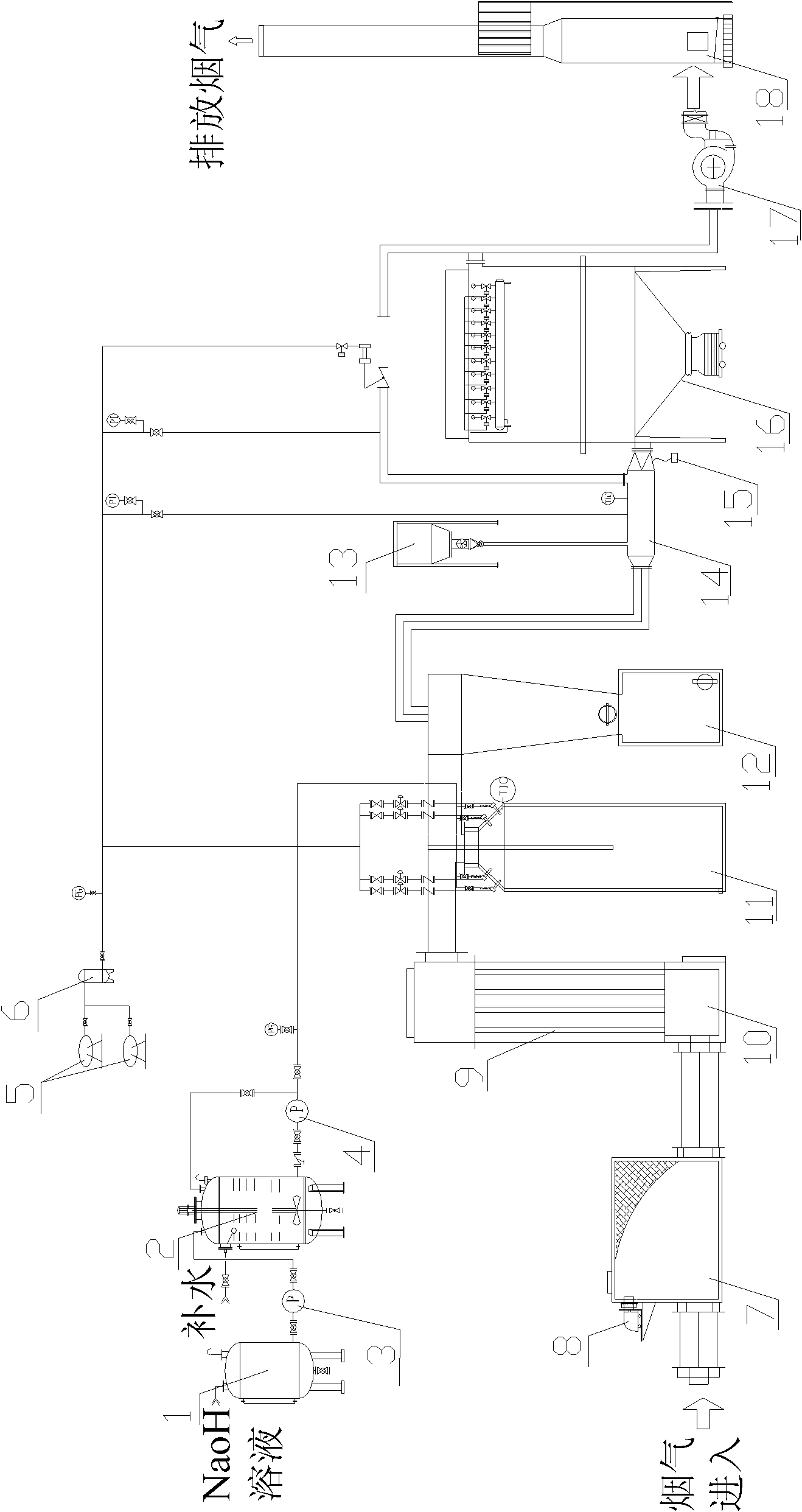

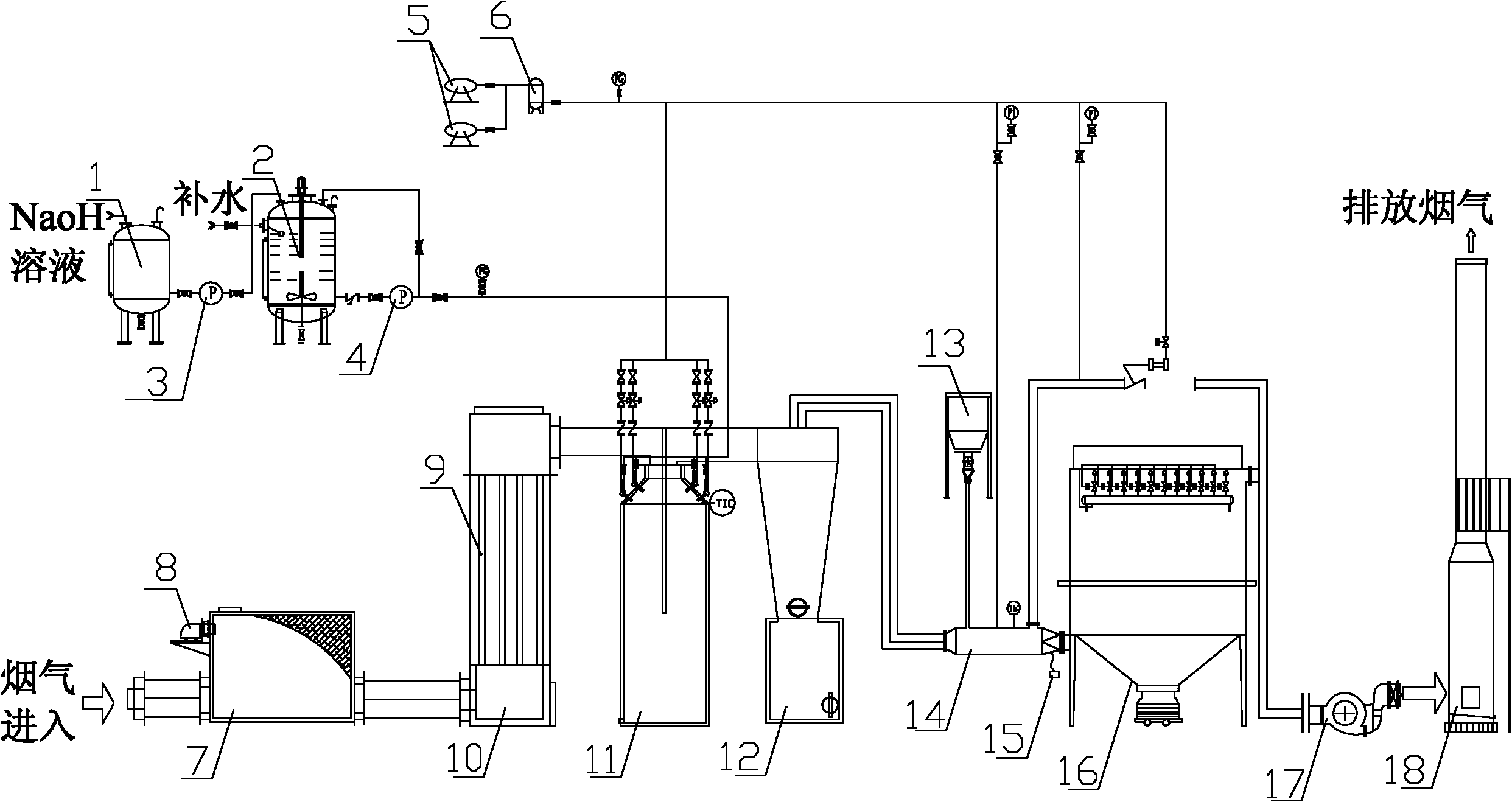

[0021] The present invention rationally combines the advantages of the existing purification device, removes target pollutants more widely, and adds a miniature flue gas combustion chamber to carry out secondary combustion of the flue gas discharged from the cremation horizontal flue, which prolongs the life of the cremation flue gas. The residence time allows it to fully burn, and realizes the secondary temperature rise of the flue gas, widening the temperature difference for the next step of the quenching device, quickly reducing the temperature of the flue gas above 500°C to below 300°C, and skipping the dioxin-like substances The synthetic temperature zone minimizes the concentration and total amount of pollutants from the source.

[0022] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0023] Such as figure 1 Shown is a structural diagram of the cremation flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com