Pyrolyzing-incinerating harmless treatment device for livestock and poultry

A processing device and pyrolysis technology, applied in the field of livestock and poultry breeding, can solve the problems of small number of diseased livestock and poultry, pollution of the surrounding environment, waste of resources, etc., and achieve the effects of universal popularization and application value, reliability and safety, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

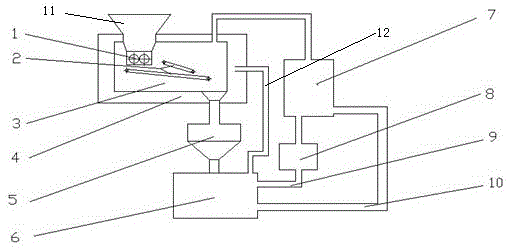

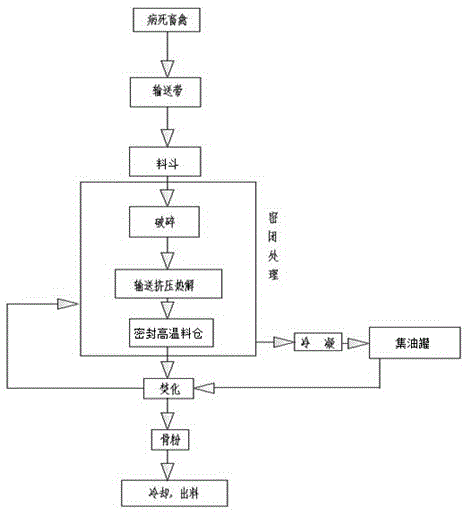

[0035] Such as figure 1 Shown is a structure diagram of a specific embodiment of a livestock and poultry pyrolysis incineration harmless treatment device according to the present invention. see figure 1 In this specific embodiment, a livestock and poultry pyrolysis incineration harmless treatment device specifically includes an incinerator 6, a feeding mechanism 11, a crusher 1, a conveyor belt 2, a sealed pyrolysis furnace 3, a sealed high-temperature silo 5, and oil and gas recovery device, the crusher 1 and the conveyor belt 2 are placed in the sealed pyrolysis furnace 3;

[0036] The bottom of the sealed pyrolysis furnace 3 is provided with a discharge port, and the outside is provided with a heating chamber 4;

[0037] The lower part of the feeding mechanism 11 is embedded from the top of the heating chamber 4 and the sealed pyrolysis furnace 3 and placed above the crusher 1, and its bottom is provided with an outlet connected to the crusher 1;

[0038] One end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com