Glycerin burning system

a burning system and glycerin technology, applied in the direction of combustion types, combustion using lumps and pulverulent fuels, lighting and heating apparatuses, etc., can solve the problems of large production and stockpiling of crude glycerin, add significant cost to the process, and existing burners cannot burn pure glycerin, so as to reduce the combustion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

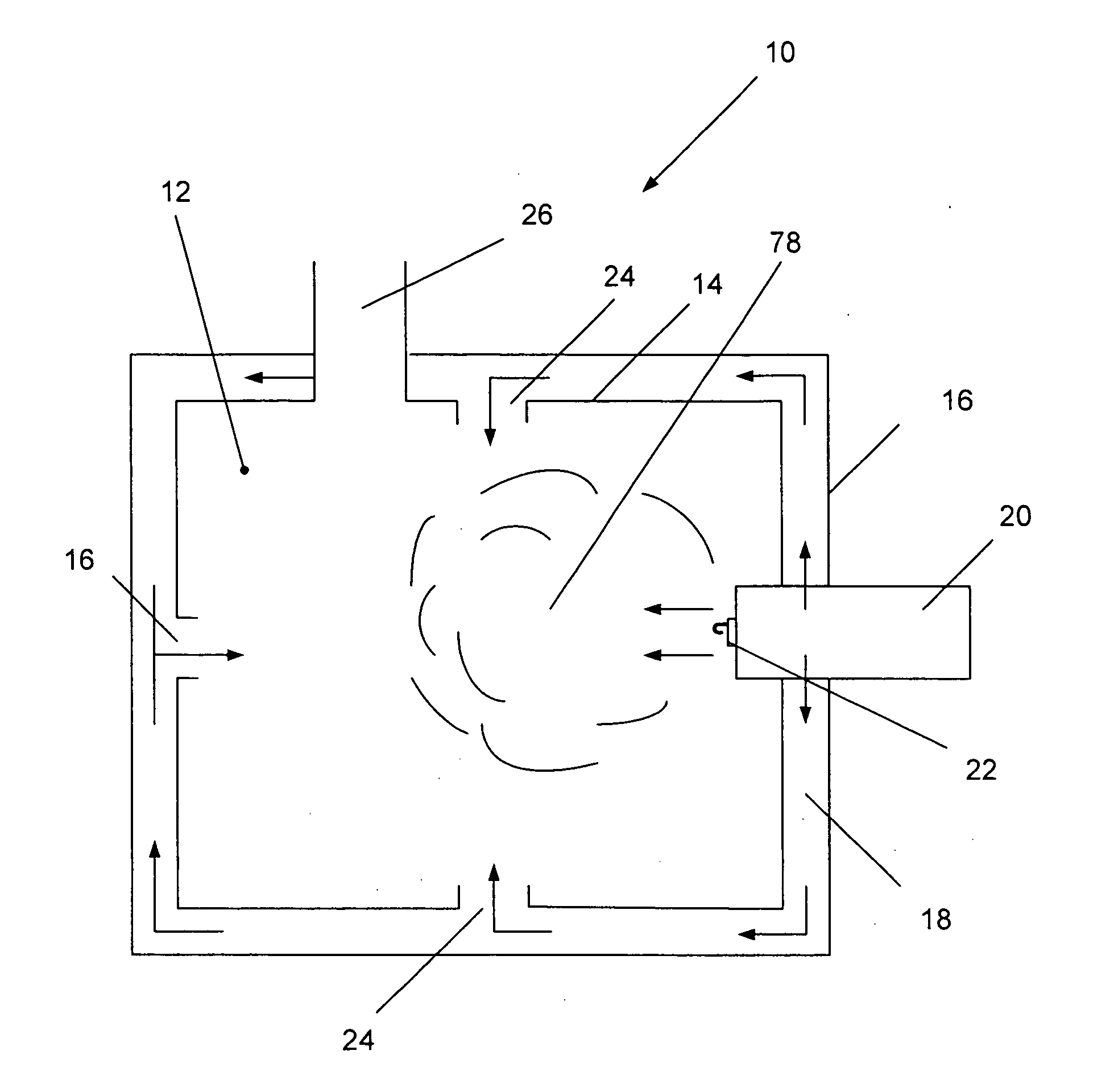

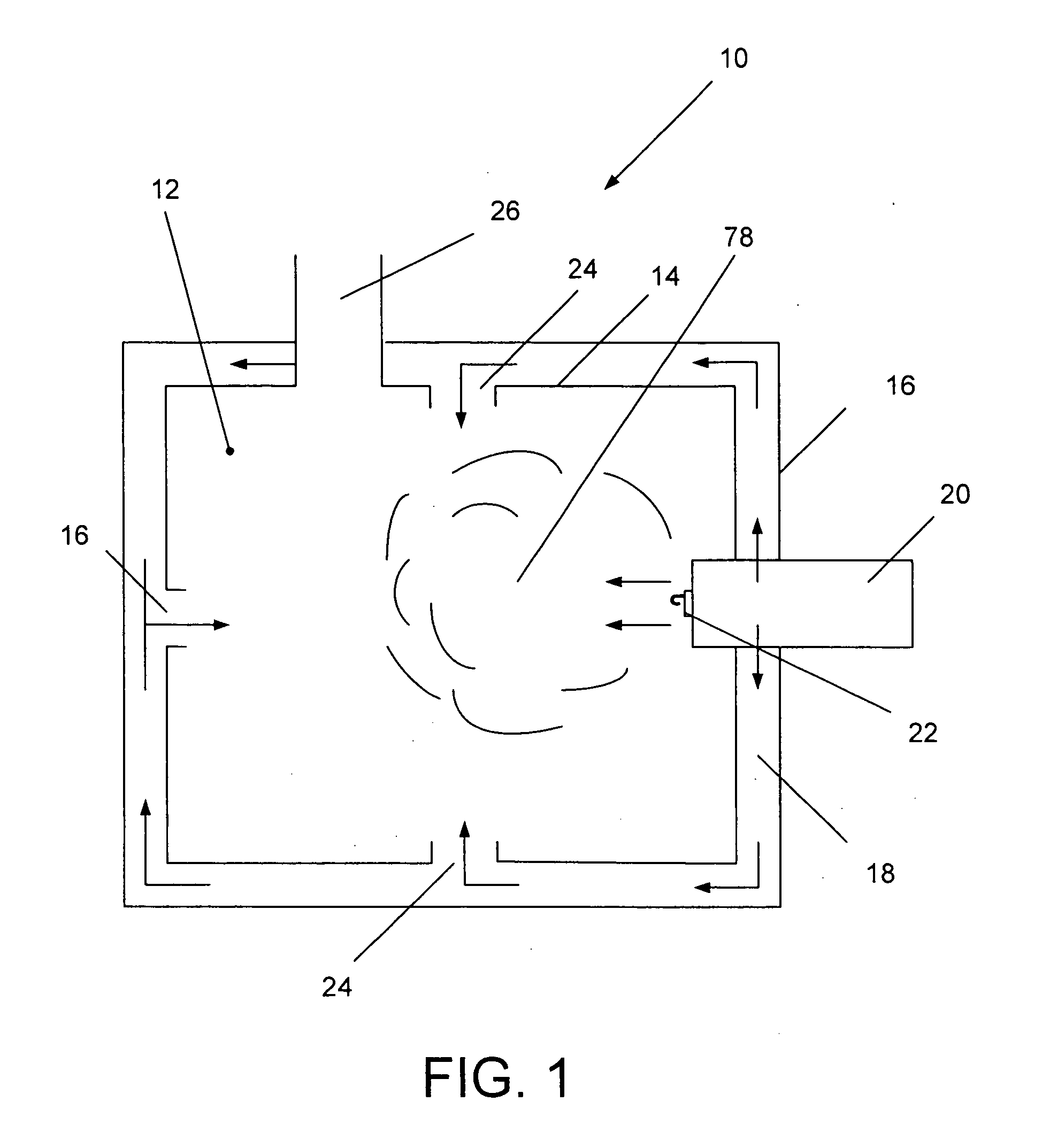

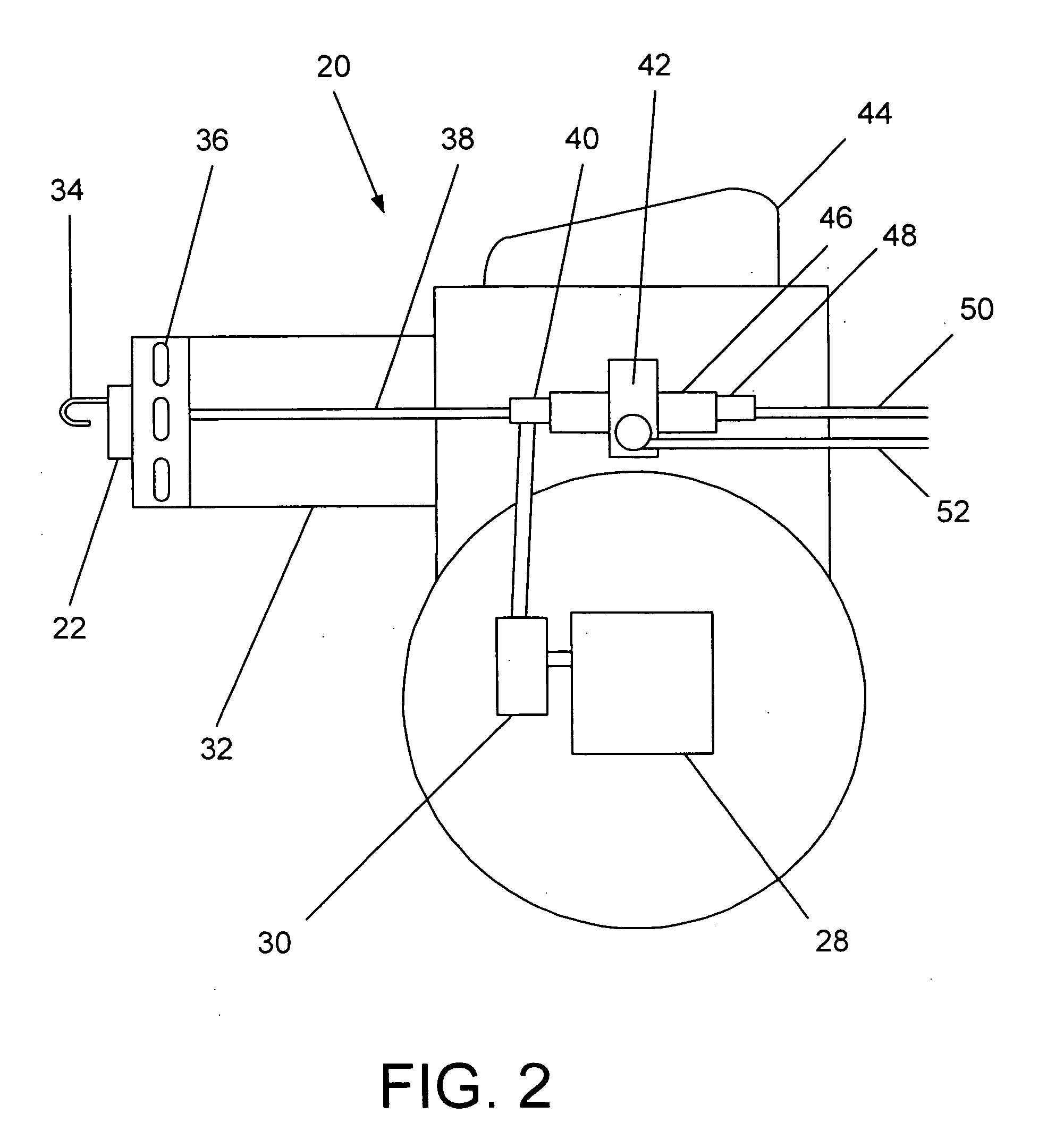

[0027]The present invention, glycerin burning system 10 is illustrated in FIG. 1. Glycerin burning system 10 may be used to burn a continuous feed of raw or pure glycerin. Glycerin burning system 10 generally includes burner 20 which expels glycerin through nozzle 22 into combustion chamber 12 where the glycerin is combusted in combustion zone 78. Exhaust gases are vented to the atmosphere through exhaust 26. Air is fed to burner 20 by a burner air blower and a portion of the air fed to burner 20 is diverted into conduit 18 which wraps around wall 14 of combustion chamber 12. Conduit 18 may be the interior region of a “jacket” surrounding wall 14 or any other conduit suitable for directing the flow of air around combustion chamber 12 while allowing the air to exchange heat with combustion chamber 12. Ports 24 and 16 are provided in wall 14 and direct heated air toward combustion zone 78. The direction of hot air towards combustion zone 78 serves two synergistic functions. First, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com