Process for using hot coal gas as viscous crude thermal recovery and gas injection boiler fuel

A technology of a steam injection boiler and a process method, which is applied to combustion methods, steam boilers, furnace tube steam boilers, etc., can solve the problems of large oil resource consumption and waste, save oil resources, help smoke exhaust, and easily effect of implementation

Inactive Publication Date: 2007-04-11

LIAOHE GASOLINEEUM EXPLORATION BUREAU

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This patented technology allows for efficient use of energy from wasted or unused gases during power generation processes like those described earlier. It also improves the performance of these systems while reducing their environmental impact on our planet's environment.

Problems solved by technology

Technological Problem: Current methods for producing heavy oils involve burning crude or refined petroleum products like gasoline into water beforehand, leading to wasted resource usage that cannot be reused effectively during future power failures due to high costs associated therewith.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

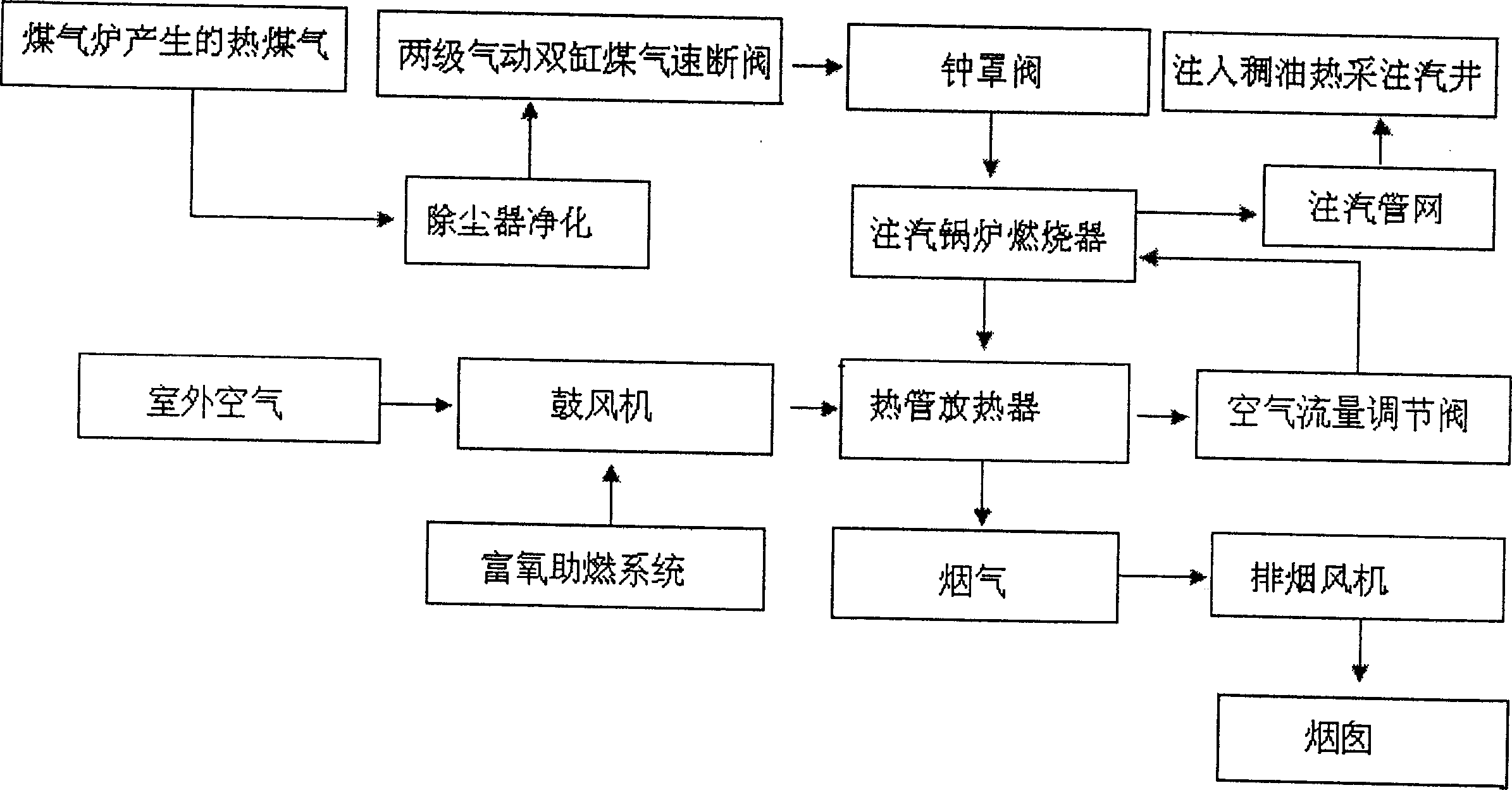

[0013] According to the technological process shown in the accompanying drawings and the above-mentioned implementation steps and technical points, hot coal gas can be used as fuel in steam injection boilers for thermal recovery of heavy oil, and qualified injection steam can be produced. This method has been successfully implemented in the Liaohe Oilfield in China and has achieved good economic benefits.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The method of utilizing hot coal gas as the fuel for thick oil hot recovering steam boiler is that the low heat value hot coal gas the hot coal gas generator generates is dedusted and conveyed to the thick oil hot recovering steam boiler so as to be burnt in the great capacity and low heat value gas combustor while preheated oxygen-rich air is supplied with one oxygen-rich combustion supporting system for high combustion efficiency. By utilizing the hot coal gas as fuel substitute can save petroleum resource and raise the combustion efficiency of hot coal gas.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Owner LIAOHE GASOLINEEUM EXPLORATION BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com