Preparation method of yttrium-stabilized nanometer zirconium dioxide powder

A nano-zirconia and yttrium stabilization technology, applied in the field of material science, can solve the problems of different particle sizes, hard agglomeration, and uneven distribution of nano-powder components, and achieve the effect of uniform distribution of yttrium elements and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

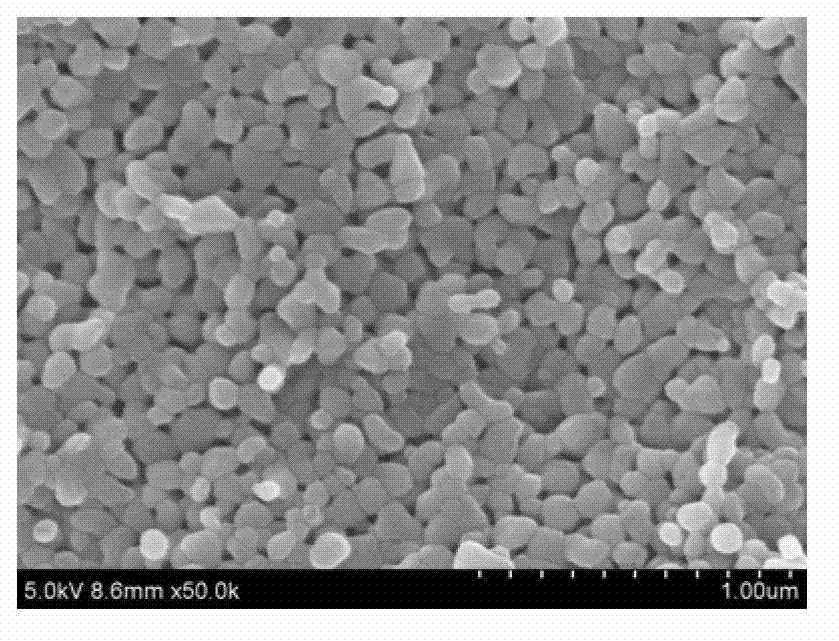

[0020] Weigh 1.0 mol of zirconium oxychloride and dissolve in deionized water to form a 4.0 mol / l solution, weigh 0.03 mol of yttrium nitrate and dissolve in deionized water to form a 2.0 mol / l solution, mix the above two solutions and stir well. Weigh 0.4 mol citric acid and dissolve it in 1.8 mol ethylene glycol, and then add it to the above solution to form a mixed solution. After the mixed solution was stirred evenly, the temperature was raised to 130° C. for 2 hours, and then the temperature was further raised to 200° C. for 4 hours to obtain a crisp black substance. Grind the above-mentioned brittle black substance, put it into a high-alumina crucible, and calcinate it in an air atmosphere at 1000°C for 2 hours to obtain yttrium-stabilized nano-zirconia powder. The above-mentioned yttrium-stabilized nano-zirconia powder was observed with a scanning electron microscope, and the results showed that the average particle size of the powder was about 100 nm, and the powder pa...

Embodiment 2

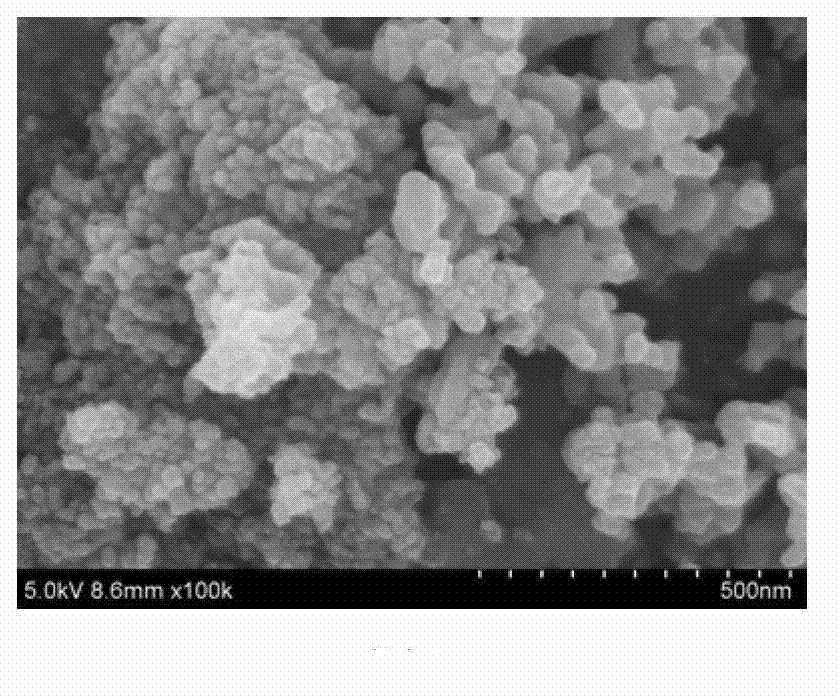

[0022] Weigh 1.0 mol of zirconium nitrate and dissolve in absolute ethanol to form a 2.0 mol / l solution, weigh 0.04 mol of yttrium acetate and dissolve in absolute ethanol to form a 1.0 mol / l solution, mix the above two solutions and stir well. Weigh 0.8 mol citric acid and dissolve it in 4.8 mol ethylene glycol, and then add it to the above solution to form a mixed solution. After the mixed solution was evenly stirred, the temperature was raised to 125° C. for 2 hours, and then the temperature was further raised to 190° C. for 2 hours to obtain a crisp black substance. Grind the above-mentioned brittle black substance, put it into a high-alumina crucible, and calcinate it in an air atmosphere at 600°C for 1 hour to obtain yttrium-stabilized nano-zirconia powder. The above-mentioned yttrium-stabilized nano-zirconia powder was observed with a scanning electron microscope, and the results showed that the average particle size of the powder was about 30 nm, and the powder particl...

Embodiment 3

[0024] Weigh 1.0 mol of zirconium acetate and dissolve in absolute ethanol to form a 1.0 mol / l solution, weigh 0.02 mol of yttrium nitrate and dissolve in deionized water to form a 1.0 mol / l solution, mix the above two solutions and stir well. Weigh 1.0 mol of citric acid and dissolve it in 4.0 mol of ethylene glycol, and then add it to the above solution to form a mixed solution. After the mixed solution was stirred evenly, the temperature was raised to 135° C. for 4 hours, and then the temperature was further raised to 220° C. for 2 hours to obtain a crisp black substance. Grind the above-mentioned brittle black substance, put it into a high-alumina crucible, and calcinate it in an air atmosphere at 900°C for 1 hour to obtain yttrium-stabilized nano-zirconia powder. The above-mentioned yttrium-stabilized nano-zirconia powder was observed with a scanning electron microscope, and the results showed that the average particle size of the powder was about 90 nm, and the powder pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com