Fuel full combustion method and system

A technology of full combustion and fuel, applied in the charging system, fuel heat treatment device, combustion engine and other directions, can solve the problems of polluting the environment and low fuel combustion efficiency, and achieve the effect of ensuring service life, improving utilization rate and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

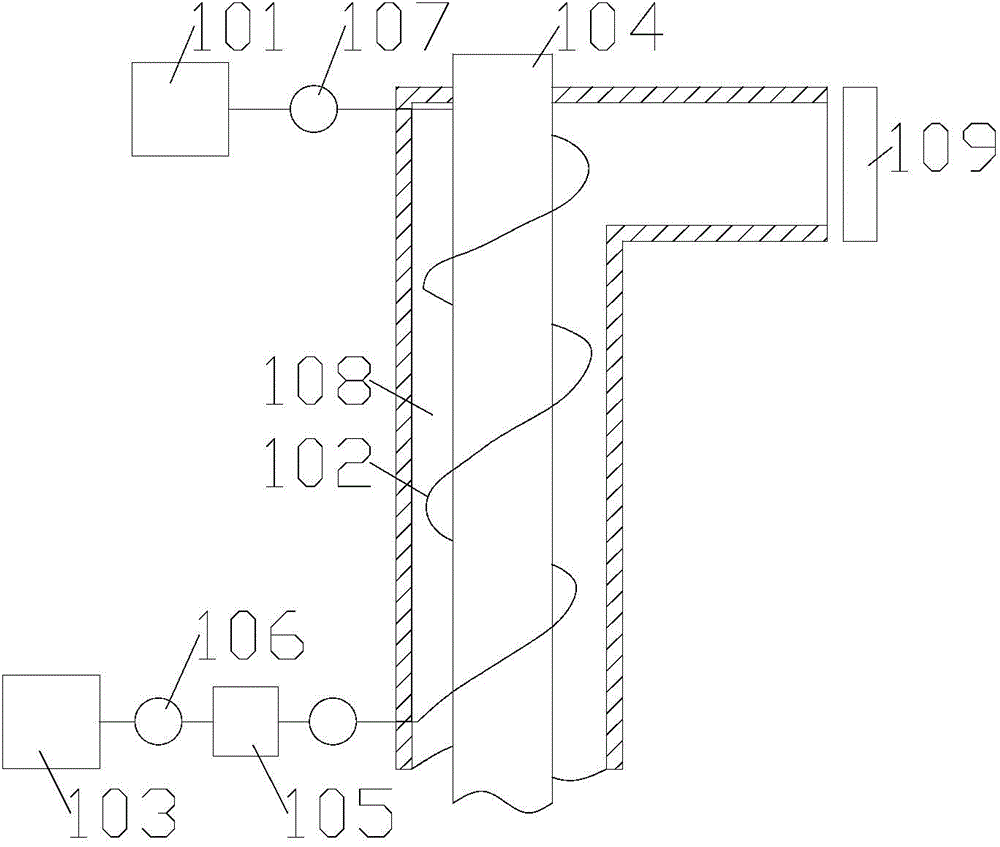

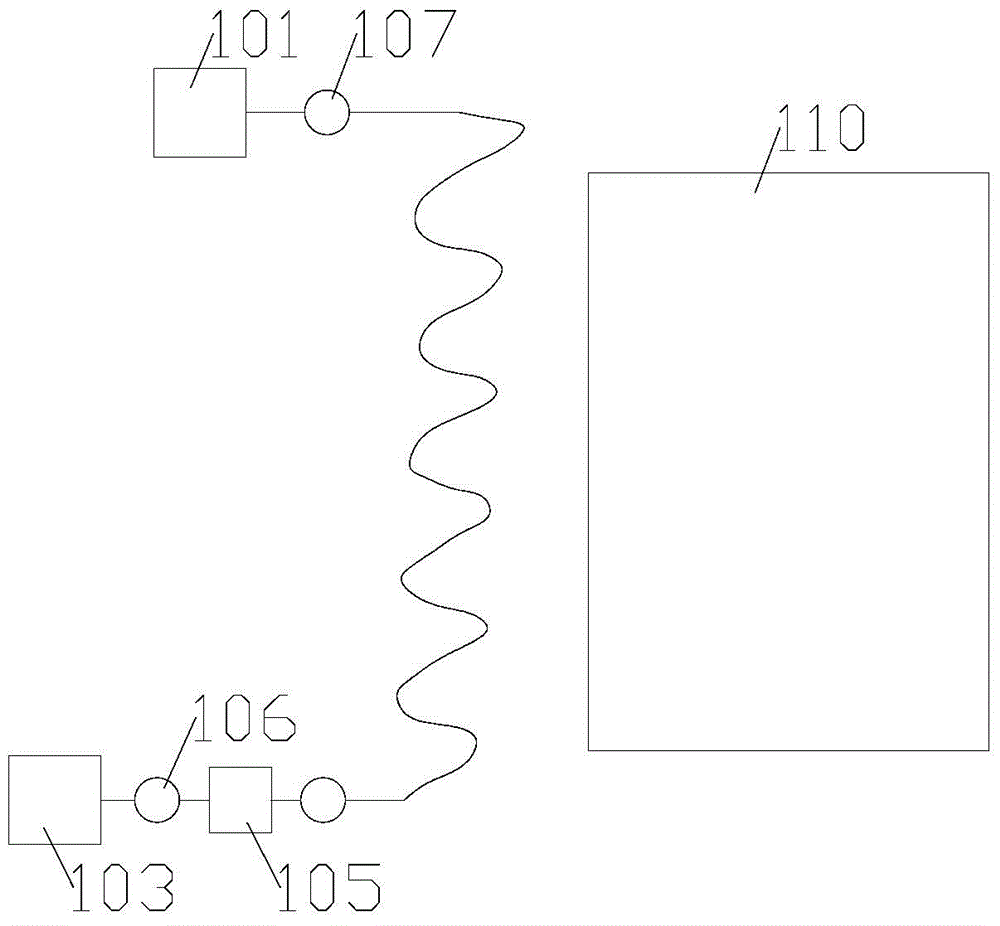

[0026] The internal combustion engine is a kind of heat engine, which can convert the chemical energy of the fuel into mechanical energy. The general method is that the fuel and air are mixed and burned to generate heat energy. The gas expands when heated, and is converted into mechanical energy by a mechanical device to perform external work. The fuel combustion efficiency of the existing internal combustion engine Low, black objects will be discharged after the combustion is completed, seriously polluting the environment.

[0027]In order to improve the above problems, the present invention provides a method and system for fully burning fuel. The fuel in the fuel tank enters the engine through the first oil delivery pipe for combustion, and the residual heat is discharged through the exhaust flue; the first oil delivery pipe is set at On the outside of the exhaust flue, the heat continuously heats the fuel in the first oil delivery pipe through the exhaust flue. During the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com