Method for comprehensively recovering valuable metal from copper smelting ash

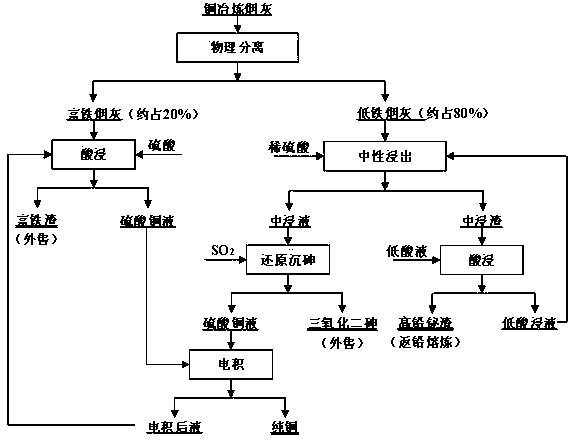

A soot and neutral technology, applied in chemical instruments and methods, improvement of process efficiency, solid separation and other directions, can solve the problems of low concentration of leachate, three wastes, unfavorable environmental protection, etc., and achieve the effect of reducing arsenic content and improving acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

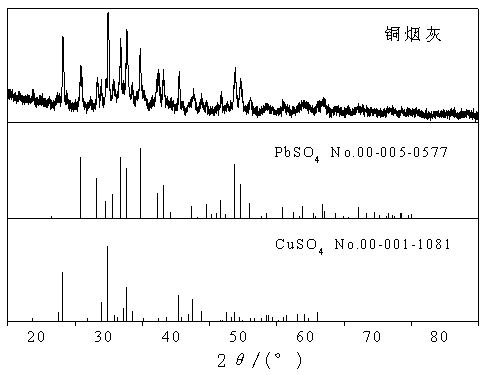

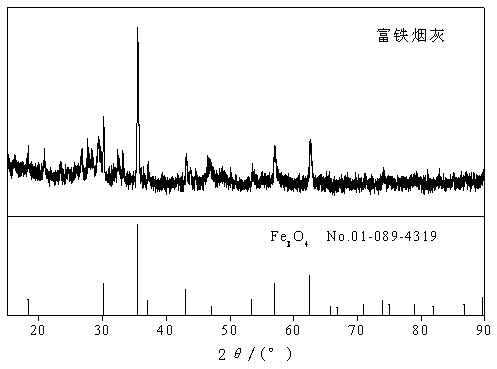

[0029] 100g copper smelting soot (w Cu 15.22%, w Fe 9.50%, w As 8.40%, w Pb 12.22%, w Bi 3.2%) under the magnetic induction intensity of 0.55T, physical separation was carried out to obtain 20.5g of iron-rich soot and 79.5g of low-iron soot; the iron-rich soot was treated with 2mol / L sulfuric acid at a liquid-solid ratio of 3:1, at a temperature of 75°C, and time leaching for 1 hour at a rotational speed of 300r / min to obtain iron-rich slag and copper sulfate solution; low-iron soot was subjected to 0.05mol / L sulfuric acid at a liquid-solid ratio of 3:1 at a temperature of 75°C for 1 hour and a rotational speed of 300r / min Min leaching to obtain medium leaching residue and medium leaching liquid; medium leaching residue is leached with 0.2 mol / L sulfuric acid at a liquid-solid ratio of 3:1, at a temperature of 75°C, for 1 hour, and at a speed of 300r / min to obtain high lead Bismuth slag and acid leaching solution; 2 The input volume is 3 times of the theoretical volume, S...

Embodiment 2

[0032] 100g copper smelting soot (w Cu 15.22%, w Fe 9.50%, w As 8.40%, w Pb 12.22%, w Bi 3.2%) at a magnetic induction of 0.4T for physical separation to obtain 23.6g of iron-rich soot and 76.4g of low-iron soot; the iron-rich soot was treated with 2mol / L sulfuric acid at a liquid-solid ratio of 4:1, at a temperature of 85°C, and time leaching for 1 hour at a rotation speed of 300r / min to obtain iron-rich slag and copper sulfate solution; low-iron soot was subjected to 0.04mol / L sulfuric acid at a liquid-solid ratio of 4:1 at a temperature of 85°C for 1 hour and a rotation speed of 300r / min Min leaching to obtain medium leaching residue and medium leaching liquid; medium leaching residue is leached with 0.4 mol / L sulfuric acid at a liquid-solid ratio of 4:1, at a temperature of 85°C, for 1 hour, and at a speed of 300r / min to obtain high lead Bismuth slag and acid leaching solution; 2 The input amount is 1 times of the theoretical amount, SO 2 The flow rate is 1 L / min, th...

Embodiment 3

[0035] 100g copper smelting soot (wCu 15.22%, w Fe 9.50%, w As 8.40%, w Pb 12.22%, w Bi 3.2%) at a magnetic induction of 0.7T for physical separation to obtain 22.8g of iron-rich soot and 77.2g of low-iron soot; the iron-rich soot was treated with 2mol / L sulfuric acid at a liquid-solid ratio of 5:1 at a temperature of 85°C for a time leaching for 1 hour at a rotational speed of 400r / min to obtain iron-rich slag and copper sulfate solution; low-iron soot was subjected to 0.02mol / L sulfuric acid at a liquid-solid ratio of 5:1 at a temperature of 85°C for 1 hour and a rotational speed of 300r / min Min leaching to obtain medium leaching residue and medium leaching liquid; medium leaching residue is leached with 0.2 mol / L sulfuric acid at a liquid-solid ratio of 5:1, at a temperature of 85°C, for 1 hour, and at a speed of 400r / min to obtain high lead Bismuth slag and acid leaching solution; 2 The input amount is 1 times of the theoretical amount, SO 2 The flow rate is 5 L / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com