Catalyst for solid oxide fuel cell cathode and preparation method of catalytic cathode

A fuel cell cathode and solid oxide technology, which is applied to solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve the problems of fast degradation rate and high operating temperature, and achieve low degradation rate, uniform composition and thickness, and excellent electrochemical performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

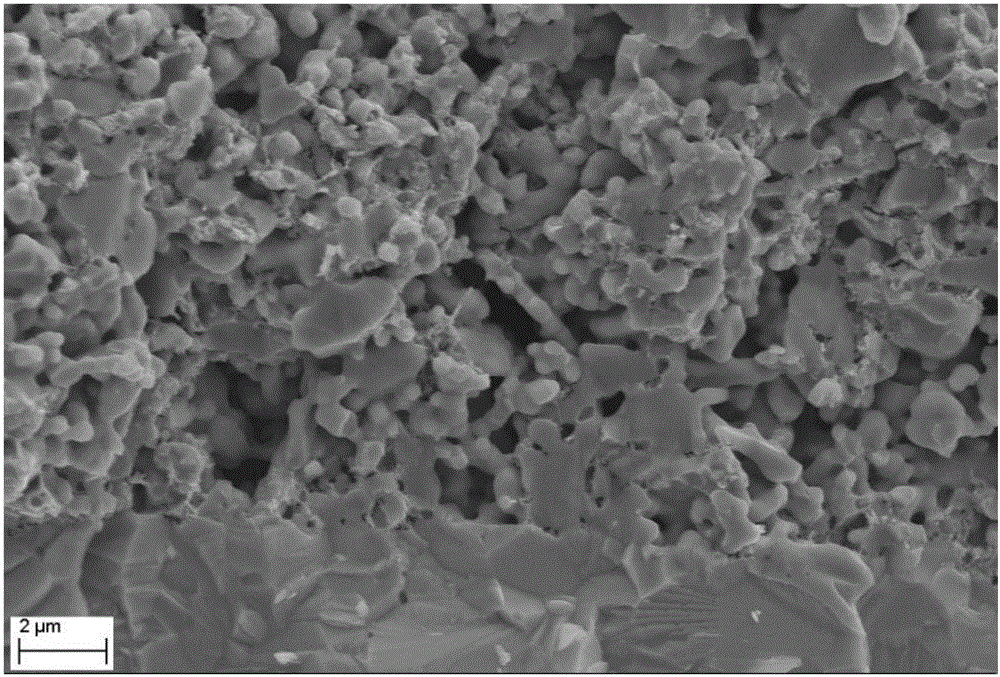

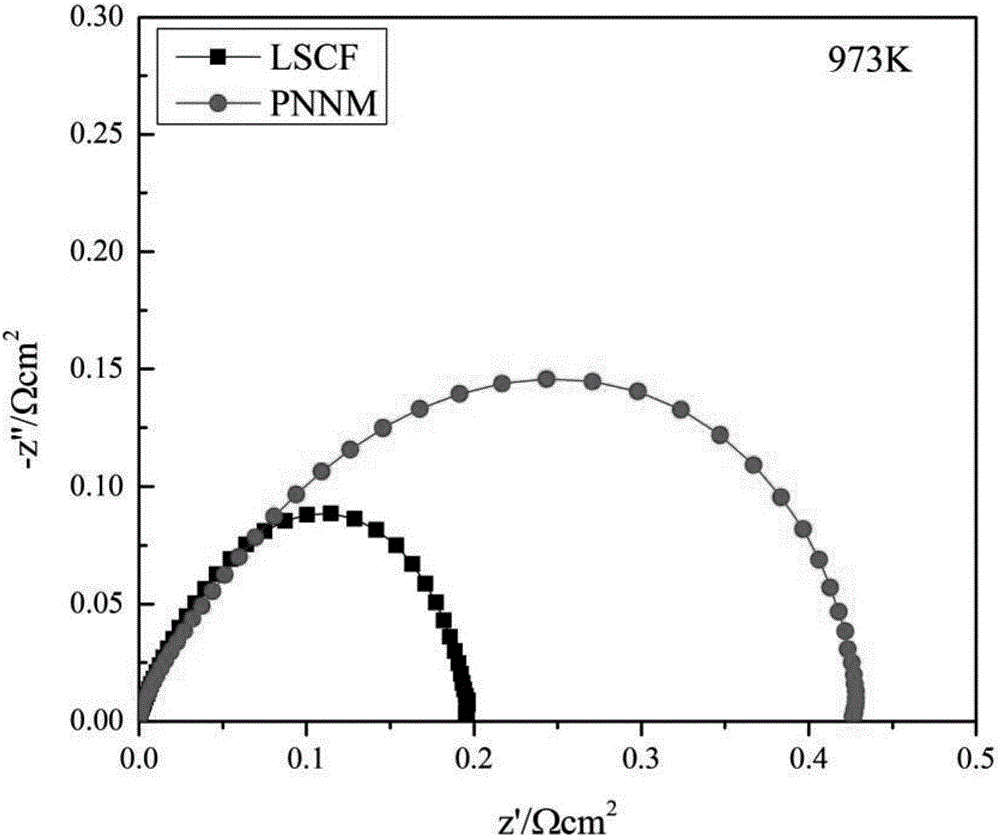

[0033] Embodiment 1 Catalyst Pr 1.99 Nd 0.01 Ni 1-x mn x o 4-δ (PNM) and the preparation of PNNM catalyzed LSCF cathode, wherein X=0.035

[0034] The preparation method is realized in the following steps:

[0035] 1) First, according to the chemical formula Pr of the impregnated substance 1.99 Nd 0.01 Ni 1-x mn x o 4-δ (PNM), configure the nitrate Pr(NO 3 ) 3 ·6H 2 O, Nd(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 4H 2 The ethanol solution of O, wherein x is 0.035 in the chemical formula, according to metal atom (Pr+Nd+Ni+Mn): the substance ratio (molar ratio) of citric acid molecule is that 1: 1 ratio adds citric acid;

[0036] 2) At room temperature, the nitrate ethanol solution was stirred electromagnetically for 2 hours to completely dissolve and complex the nitrate to obtain a PNNM catalyst or be called a PNNM ethanol solution,

[0037] 3) Apply the LSCF slurry on the electrolyte by the screen printing method, put it in the sample incubator...

Embodiment 2

[0039] Embodiment 2 Catalyst Pr 1.99 Nd 0.01 Ni 1-x mn x o 4-δ (PNNM) and preparation of PNNM-catalyzed LSCF cathode, where X=0.065.

[0040] The preparation method is the same as Example 1, except that the chemical formula Pr is different from the example 1.99 Nd 0.01 Ni 1-x mn x o 4-δ X is 0.065, the configuration of nitrate matches this chemical formula, and the impregnation volume of PNNM in step 4) is 1.8 μL / mm 2 , other steps and parameters are the same as in Example 1.

Embodiment 3

[0041] Embodiment 3 Catalyst Pr 1.99 Nd 0.01 Ni 1-x mn x o 4-δ (PNNM) and preparation of PNNM-catalyzed LSCF cathode, where X=0.05.

[0042] The preparation method is the same as Example 1, except that the chemical formula Pr is different from Example 1 1.99 Nd 0.01 Ni 1-x mn x o 4-δ X is 0.05, the configuration of nitrate matches this chemical formula, and the impregnation volume of PNNM in step 4) is 1.8 μL / mm 2 , other steps and parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com