Three-dimensional graphene/ carbon nano tube based molybdenum disulfide/cobaltous sulfide composite material electrocatalyst as well as preparation method and application thereof

A carbon nanotube, molybdenum disulfide technology, applied in electrodes, electrolysis process, electrolysis components, etc., to achieve the effect of prolonging cycle life, simple preparation process, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

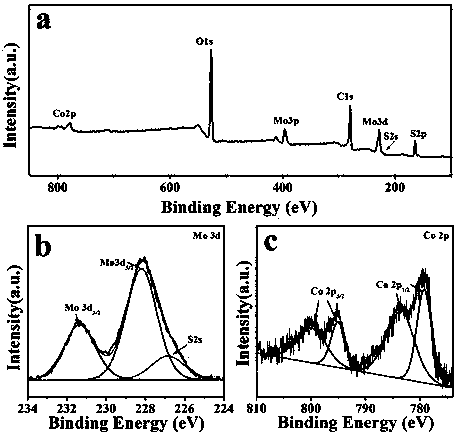

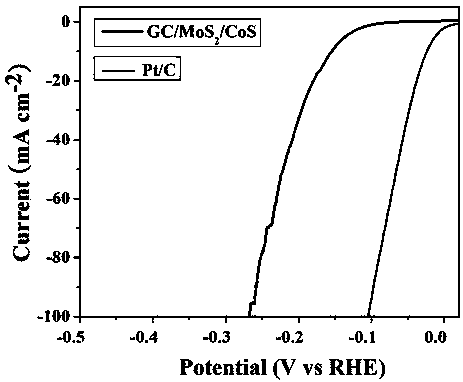

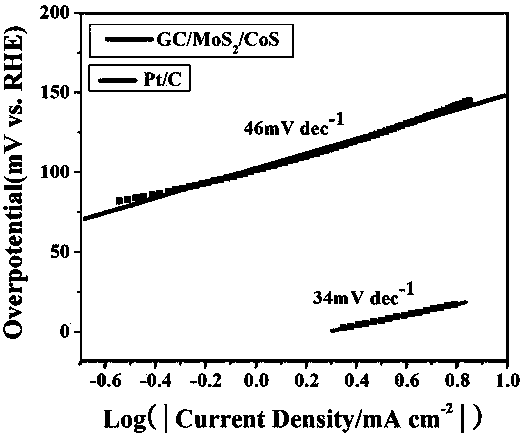

[0027] Sample preparation: Measure 20ml of graphene oxide (GO) solution with a concentration of 1mg / ml, add 4mg of hydroxylated multi-walled carbon nanotubes (CNTs-OH), after ultrasonication for two hours, add 80mg of ascorbic acid, 200 mg of Sodium molybdate water and 98 mg of cobalt chloride hexahydrate, the molar ratio of molybdenum source content to cobalt source content is 2:1, and finally 400 mg of thiourea is added sonicated until completely dissolved, and moved to a 100 ml reaction kettle. Put the reactor into an oven, set the temperature at 180 °C, and react for 24 h. After the reaction, cool down, filter the product in the reactor with suction, wash three times with distilled water to obtain a hydrogel-like solid substance, and freeze-dry to obtain a three-dimensional columnar structure of graphene / carbon nanotube-based molybdenum disulfide / cobalt sulfide composite Electrocatalysis (GC4 / MoS 2 / CoS).

[0028] Electrocatalytic application: 2 mg of sample is dispersed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com