Preparation method of size controllable rhotanium nano particles

A nanoparticle, gold-palladium alloy technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., to achieve the effect of simple operation, uniform dispersion and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

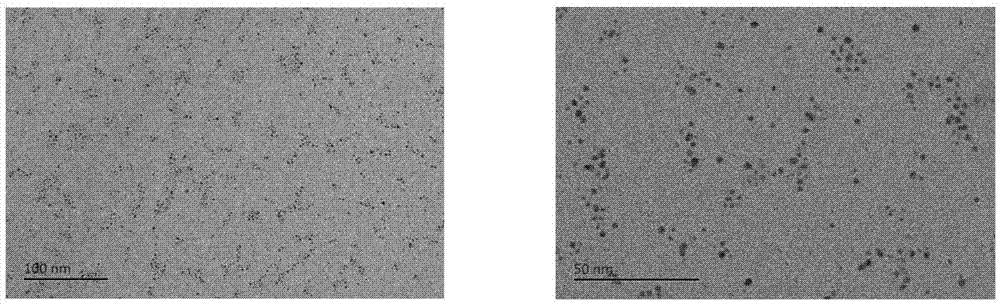

[0024] Synthesis of about 3nm gold-palladium alloy of embodiment 1

[0025] Dissolve the gold organic complex and palladium chloride in tetrahydrofuran, methanol or ethanol solvent, the molar ratio of the gold organic complex to palladium chloride is 1:1, the molar concentration of the gold organic complex in the organic solvent is 3mg / ml, stirred at room temperature for 30 minutes, then added phenethanethiol ligand and stirred for one hour until a large amount of orange precipitate was formed, the molar ratio of the sum of thiol ligand to gold organic complex and palladium chloride is 0.25:1. Finally, an aqueous sodium borohydride solution with a molar ratio of 15:1 to the sum of the gold organic complex and palladium chloride was added to the above reaction, and a black precipitate was formed immediately. After the reaction was carried out for 20 hours, the thiol ligand was washed 4 times with a large amount of methanol, the product was extracted 2 times with dichlorometha...

Embodiment 2

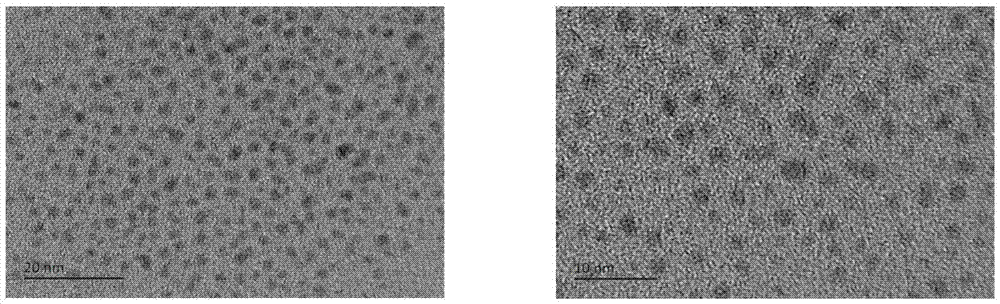

[0027] The synthesis of embodiment 2 2-2.5nm gold-palladium alloy

[0028] Dissolve the gold organic complex and palladium chloride in tetrahydrofuran, methanol or ethanol solvent, the molar ratio of the organic gold source to palladium chloride is 1:1, the molar concentration of the gold organic complex in the organic solvent is 3mg / ml , stirred at room temperature for 30 minutes, then added phenylethyl thiol ligand and stirred for one hour until a large amount of orange precipitate was formed, wherein the molar ratio of thiol ligand to metal source was 0.5:1. Finally, an aqueous sodium borohydride solution with a molar ratio of 15:1 to the sum of the gold organic complex and palladium chloride was added to the above reaction, and a black precipitate was formed immediately. After the reaction was carried out for 20 hours, the thiol ligand was washed 4 times with a large amount of methanol, the product was extracted 2 times with dichloromethane, and the product dissolved in di...

Embodiment 31

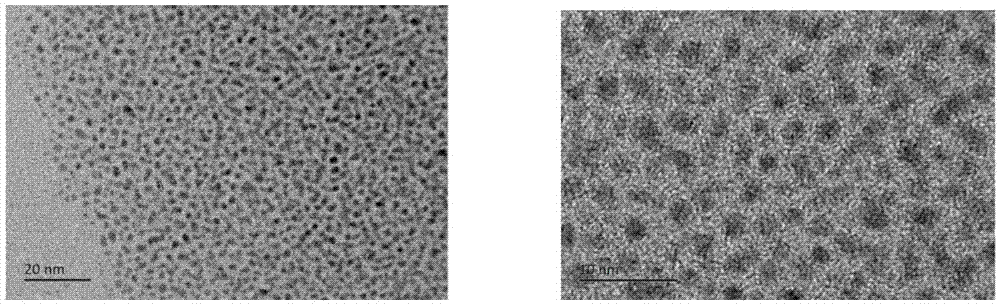

[0030] The synthesis of embodiment 3 1.7-2nm gold-palladium alloy

[0031] Dissolve the gold organic complex and palladium chloride in tetrahydrofuran, methanol or ethanol solvent, the molar ratio of the organic gold source to palladium chloride is 1:1, the molar concentration of the gold organic complex in the organic solvent is 3mg / ml , stirred at room temperature for 30 minutes, then added phenylethyl thiol ligand and stirred for one hour until a large amount of orange precipitate was formed, wherein the molar ratio of thiol ligand to metal source was 1:1. Finally, an aqueous sodium borohydride solution with a molar ratio of 15:1 to the sum of the gold organic complex and palladium chloride was added to the above reaction to immediately generate a black precipitate. After the reaction was carried out for 20 hours, the thiol ligand was washed 4 times with a large amount of methanol, the product was extracted 2 times with dichloromethane, and the product dissolved in dichloro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com