Modified polyaniline adsorbent and application of modified polyaniline adsorbent in wastewater treatment

A polyaniline and adsorbent technology, which is applied in the field of polyaniline adsorbent preparation, can solve the problems of difficult separation of resin and heavy metal ions, incomplete treatment of heavy metal ions, secondary pollution, etc., and achieves easy popularization, convenient implementation, and easy separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

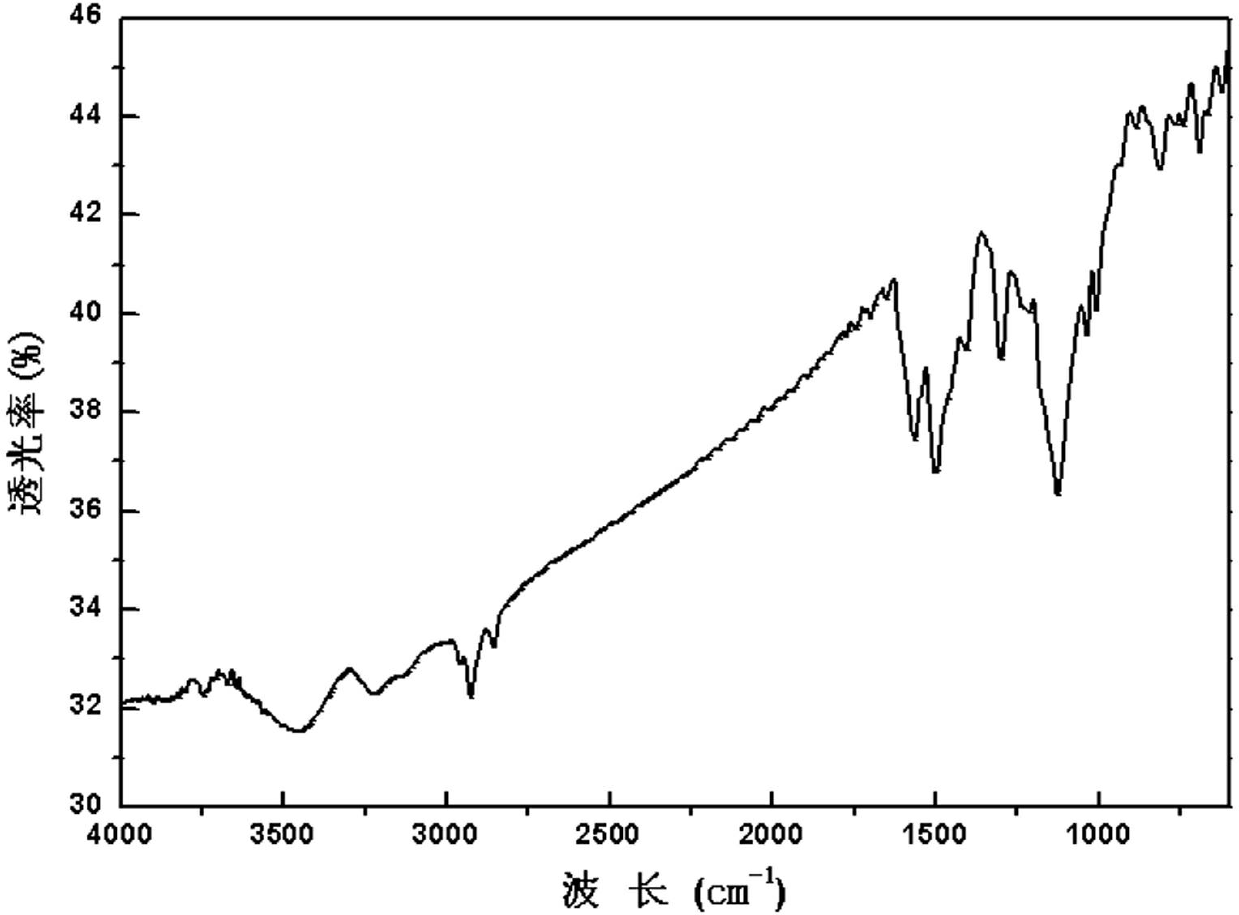

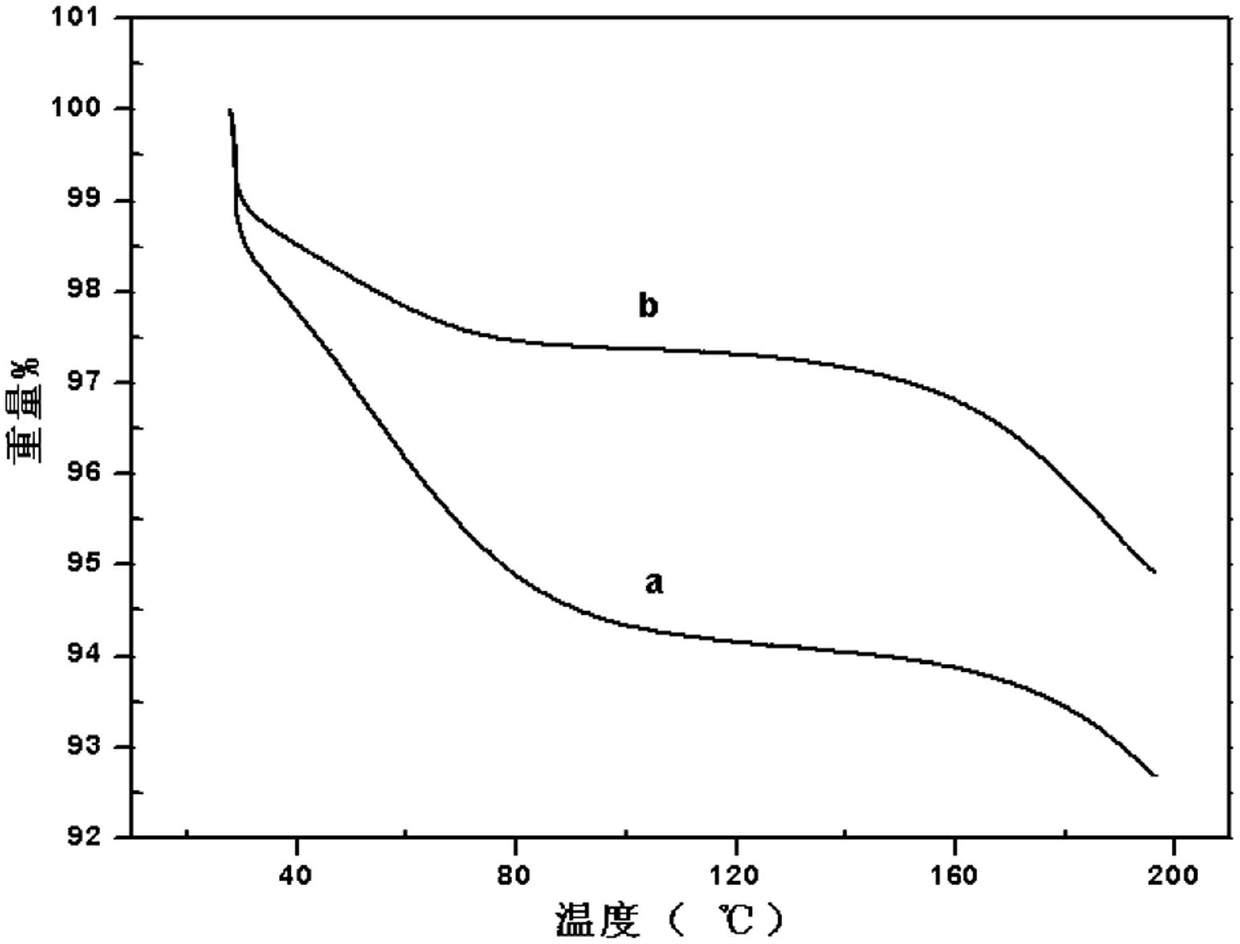

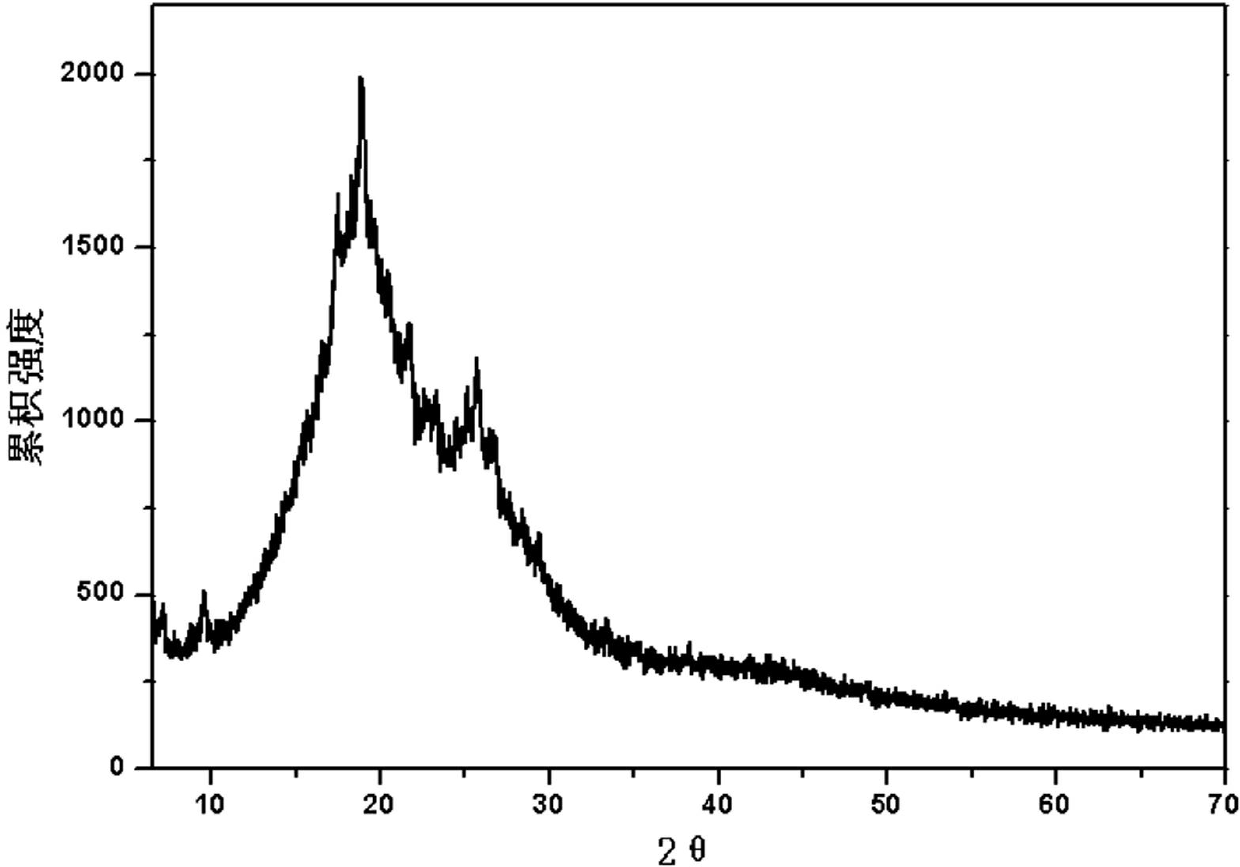

[0029] Example 1: Preparation of modified polyaniline adsorbent

[0030] Dissolve 10g of sodium dodecylbenzenesulfonate in 500ml of water and stir for 2-5 hours; add 2g of aniline (AN) and continue stirring for 2-5 hours; add 4.9g of ammonium persulfate, and adjust the pH of the mixed solution first. 2. Continue to stir for 24 hours; filter with suction to wash the solid precipitate; dry and grind into powder to obtain the modified polyaniline adsorbent (PANSDBS).

Embodiment 2

[0031] Embodiment two: the preparation of modified polyaniline adsorbent

[0032] Dissolve 10g of sodium hexadecylbenzenesulfonate in 500ml of water and stir for 2-5 hours; add 2-4g of aniline (AN) and continue stirring for 2-5 hours; add 8.2g of ammonium persulfate to adjust the mixing solution pH=3, continue to stir for 24 hours; filter with suction to wash the solid precipitate; dry and grind into powder to obtain the modified polyaniline adsorbent.

Embodiment 3

[0033] Embodiment three, the preparation of modified polyaniline adsorbent

[0034] Dissolve 10g sodium perfluorooctane sulfonate in 500ml water, stir for 2~5 hours; add 5g aniline (AN), continue stirring for 2~5 hours; add 12.3g ammonium persulfate, first adjust the pH of the mixed solution to 2.5 , continue to stir for 24 hours; filter with suction to wash the solid precipitate; dry and grind into powder to obtain the modified polyaniline adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com