Method for preparing nano-gamma-Fe2O3 hollow magnetic microsphere

A technology of magnetic microspheres and hollow spheres, applied in the direction of iron oxide/iron hydroxide, iron oxide, etc., can solve the problems of complex operation, difficult process control, less preparation, etc., and achieve high product purity, low raw materials, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Weigh 0.30g of DBS into 100ml of deionized water, stir thoroughly for 30min, add 0.27g of ferric chloride and 0.20g of ferric sulfate, stir for a while, add 1.5g of urea and continue stirring. Then it was transferred into a 250ml three-hole bottle and refluxed at 100°C for 3h. The obtained precipitate was centrifuged, water-settled, and alcohol-settled, then put into an oven, and dried at 100°C;

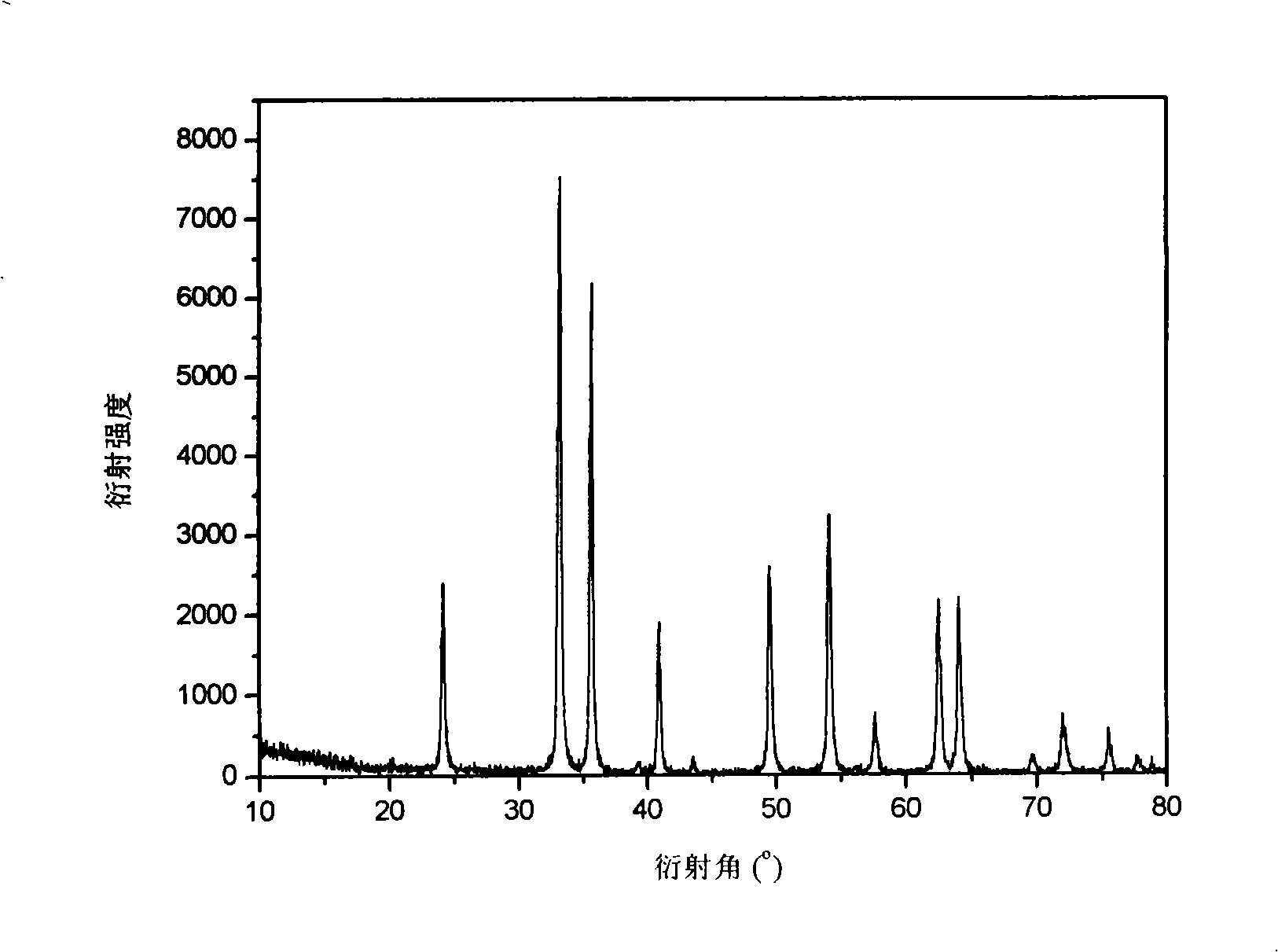

[0014] Put the above powder into a muffle furnace for heat treatment at 300°C for 2 hours, then put it into a quartz tube furnace at 350°C H 2 Heat treatment under atmosphere for 2h, then slowly drop to 200°C in O 2 The final product can be obtained by heat treatment under atmosphere for 2 hours. The product is a hollow spherical structure composed of short nanorods with good crystallinity. The crystal phase composition of the product is as figure 1 shown.

Embodiment 2

[0016] Weigh 0.50g of DBS into 100ml of deionized water, stir thoroughly for 30min, add 0.27g of ferric chloride and 0.25g of ferric sulfate, stir for a while, add 1.8g of urea and continue stirring. Then it was transferred to a 250ml three-hole bottle and refluxed at 100°C for 5h. The obtained precipitate was centrifuged, washed with water, and washed with alcohol, and then put into an oven and dried at 100°C;

[0017] Put the above powder into a muffle furnace for heat treatment at 300°C for 2 hours, then put it into a quartz tube furnace at 350°C H 2 Heat treatment under atmosphere for 2h, then slowly drop to 200°C in O 2 The final product can be obtained by heat treatment under atmosphere for 3 hours. The product is a hollow spherical structure composed of short nanorods with good crystallinity.

Embodiment 3

[0019] Weigh 0.40g of DBS into 100ml of deionized water, stir thoroughly for 30min, add 0.27g of ferric chloride and 0.18g of ferric sulfate, stir for a while, add 1.40g of urea and continue stirring. Then it was transferred into a 250ml three-hole bottle and refluxed at 100°C for 2h. The obtained precipitate was centrifuged, washed with water, and washed with alcohol, and then put into an oven and dried at 100°C;

[0020] Put the above powder into a muffle furnace for heat treatment at 350°C for 1h, then put it into a quartz tube furnace at 300°C H 2 Heat treatment under atmosphere for 3h, then slowly lower to 180°C in O 2 The final product can be obtained by heat treatment under atmosphere for 3 hours. The product is a hollow spherical structure composed of short nanorods with good crystallinity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com