Material for preparing degradable bionic fish bait

A bionic fishing bait and pigment technology, which is applied in the field of materials for manufacturing degradable bionic fishing baits, can solve the problems of increased production costs, destruction of the full biodegradation characteristics of polylactic acid, etc., and achieve the effects of improving quality, improving material performance, and improving brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

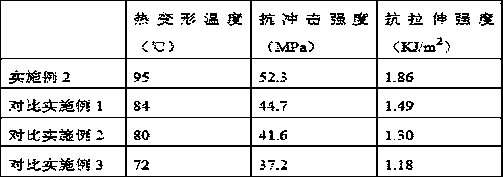

Examples

Embodiment 1

[0024] A material for making biodegradable bionic bait, made of the following substances by weight:

[0025] 100 parts of modified polylactic acid, 8 parts of toughening agent, 3 parts of nano-calcium carbonate, 0.5 part of attractant, 1 part of pigment, 0.2 part of antioxidant, 0.1 part of ultraviolet absorber, 0.5 part of lubricant.

[0026] Further, the toughening agent is methyl methacrylate-butadiene-styrene terpolymer.

[0027] Further, the particle size of the nano-calcium carbonate is 20-60nm.

[0028] Further, the food attractant is allicin.

[0029] Further, the antioxidant is antioxidant 1010.

[0030] Further, the ultraviolet absorber is ultraviolet absorber UV-531.

[0031] Further, the lubricant is polyethylene wax.

[0032] Further, the preparation method of described modified polylactic acid comprises the following steps:

[0033] (1) Mix terephthalic acid and ethylene glycol into the reaction kettle according to the molar ratio of 1:1.2, heat to keep the ...

Embodiment 2

[0037] A material for making biodegradable bionic bait, made of the following substances by weight:

[0038] 105 parts of modified polylactic acid, 10 parts of toughening agent, 4 parts of nano calcium carbonate, 1 part of food attractant, 1.5 parts of pigment, 0.3 part of antioxidant, 0.2 part of ultraviolet absorber, 0.7 part of lubricant.

[0039] Further, the toughening agent is methyl methacrylate-butadiene-styrene terpolymer.

[0040] Further, the particle size of the nano-calcium carbonate is 20-60nm.

[0041] Further, the food attractant is vanillin.

[0042] Further, the antioxidant is antioxidant 1010.

[0043] Further, the ultraviolet absorber is ultraviolet absorber UV-531.

[0044] Further, the lubricant is polyethylene wax.

[0045] Further, the preparation method of described modified polylactic acid comprises the following steps:

[0046] (1) Mix terephthalic acid and ethylene glycol into the reactor according to the molar ratio of 1:1.4, heat to keep the ...

Embodiment 3

[0050] A material for making biodegradable bionic bait, made of the following substances by weight:

[0051] 110 parts of modified polylactic acid, 12 parts of toughening agent, 5 parts of nano-calcium carbonate, 1.5 parts of food attractant, 2 parts of pigment, 0.4 part of antioxidant, 0.3 part of ultraviolet absorber, 0.8 part of lubricant.

[0052] Further, the toughening agent is methyl methacrylate-butadiene-styrene terpolymer.

[0053] Further, the particle size of the nano-calcium carbonate is 20-60nm.

[0054] Further, the food attractant is coumarin.

[0055] Further, the antioxidant is antioxidant 1010.

[0056] Further, the ultraviolet absorber is ultraviolet absorber UV-531.

[0057] Further, the lubricant is polyethylene wax.

[0058] Further, the preparation method of described modified polylactic acid comprises the following steps:

[0059] (1) Put terephthalic acid and ethylene glycol into the reaction kettle according to the molar ratio of 1:1.6, heat to ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com