Method for manufacturing polyphenylene sulfide composite film

A polyphenylene sulfide and composite film technology, applied in the field of composite film manufacturing, can solve the problem that the toughness and elongation at break of polyphenylene sulfide film have not been fundamentally solved, and the toughness and elongation at break of polyphenylene sulfide film have not been fundamentally solved. low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

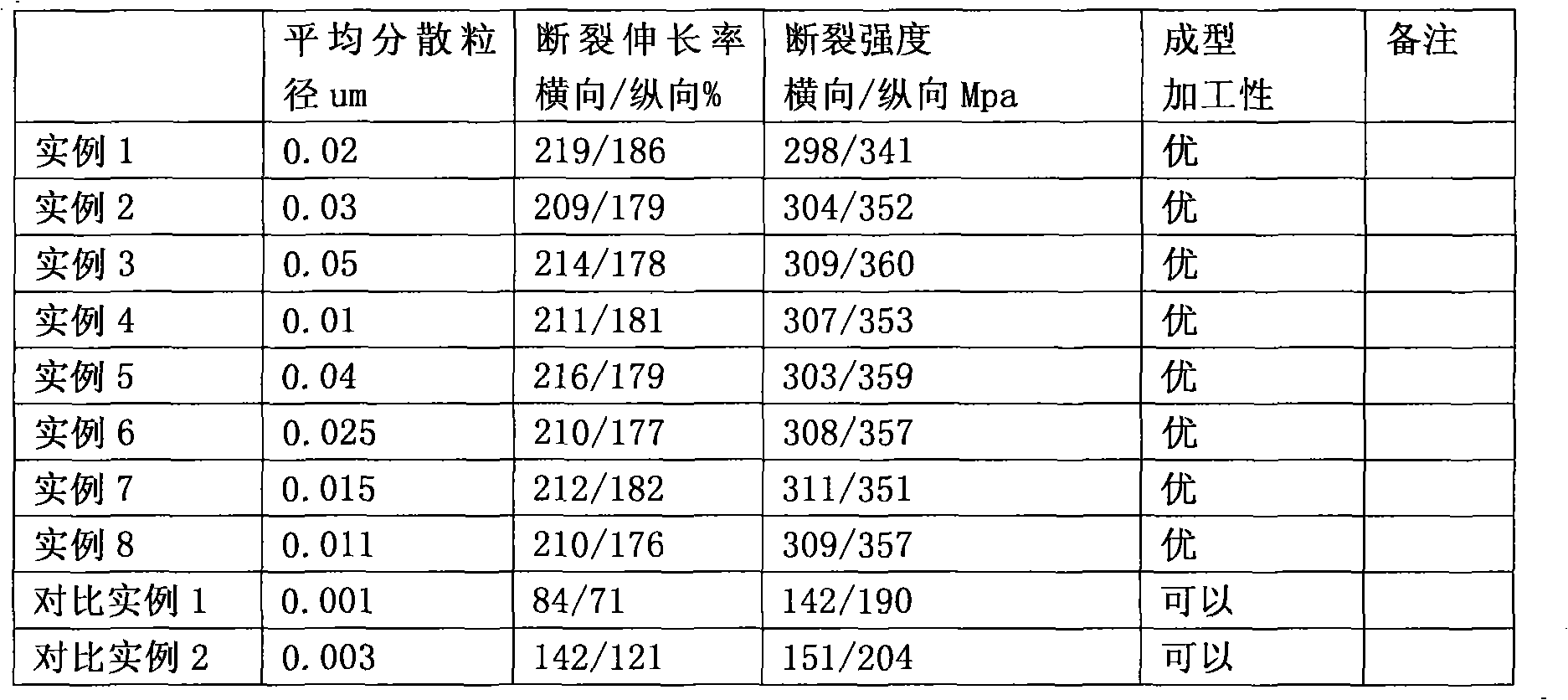

Examples

Embodiment 1

[0047] Using the above process conditions and procedures, the polyphenylene sulfide resin is pretreated, and then processed into a mixture using the following formula.

[0048] Polyphenylene sulfide resin 90%

[0049] Calcium zinc multifunctional composite heat stabilizer 1.5%

[0050] Polystyrene and ethylene copolymer elastomer 8.5%

[0051] The extrusion process and conditions of the above-mentioned extruder are used, that is, the extruder whose temperature is controlled between 290-340℃ is extruded, and it is conveyed to the film T-die nozzle incubator by the head gear pump, and is equipped on the incubator There is a metering pump. The polyphenylene sulfide melt is transported by the metering pump to a T-shaped mold with a width of 1mm and a length of 590mm. The melt is ejected from the T-shaped mold to form a sheet with a thickness of 1mm and a width of 590mm. In a belt channel with a heat preservation temperature of 120℃, it is transported from the channel to the two-way draft...

Embodiment 2

[0058] Using the above process conditions and procedures, the polyphenylene sulfide resin is pretreated, and then processed into a mixture using the following formula.

[0059] Polyphenylene sulfide resin 95%

[0060] Calcium zinc multifunctional composite heat stabilizer 0.9%

[0061] Polystyrene and ethylene copolymer elastomer 4.1%

[0062] The extrusion process and conditions of the above extruder are used, that is, the extruder whose temperature is controlled between 290-340℃ is extruded, and it is delivered to the film T-die nozzle incubator through the head gear pump, and is equipped on the incubator There is a metering pump. The polyphenylene sulfide melt is transported by the metering pump to a T-shaped mold with a width of 1.2mm and a length of 580mm. The melt is ejected from the T-shaped mold to form a sheet with a thickness of 1.2mm and a width of 580mm. The material is conveyed from the channel to the two-way drafting tunnel in a belt channel with a heat preservation tem...

Embodiment 3

[0069] The pretreated polyphenylene sulfide resin is processed using the above process conditions and processes, and then processed into a mixture using the following formula.

[0070] Polyphenylene sulfide resin 91%

[0071] Calcium zinc multifunctional composite heat stabilizer 1.0%

[0072] Polystyrene and ethylene copolymer elastomer 8.0%

[0073] Using the extrusion process and conditions of the above extruder, that is, extruded by an extruder whose temperature is controlled between 290-340℃, and transported to the film T-die nozzle incubator through the head gear pump, on the incubator Equipped with a metering pump. The polyphenylene sulfide melt is transported by the metering pump to a T-shaped mold with a width of 1.6mm and a length of 570mm. The melt is ejected from the T-shaped mold to form a sheet with a thickness of 1.6mm and a width of 570mm. , The sheet material is conveyed from the channel to the two-way drafting tunnel in a belt channel with a heat preservation temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com