Fire-retardant plastic and preparation method thereof

A technology of flame retardant plastics and flame retardants, which is applied in the field of flame retardant plastics and its preparation, can solve problems such as uneven dispersion of metal oxides and affect the flame retardant effect, and achieve good market prospects, good flame retardant effect, and good barrier sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

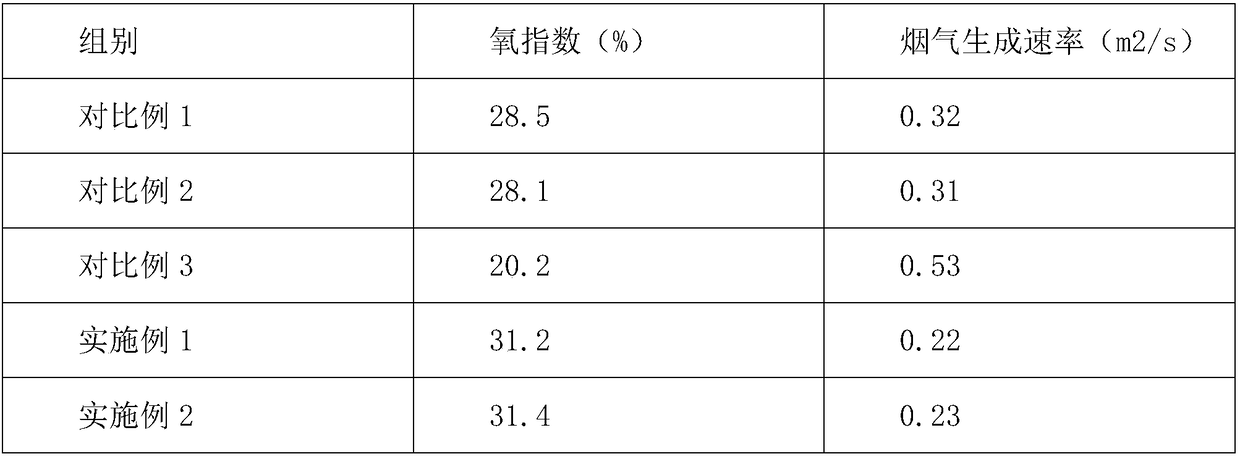

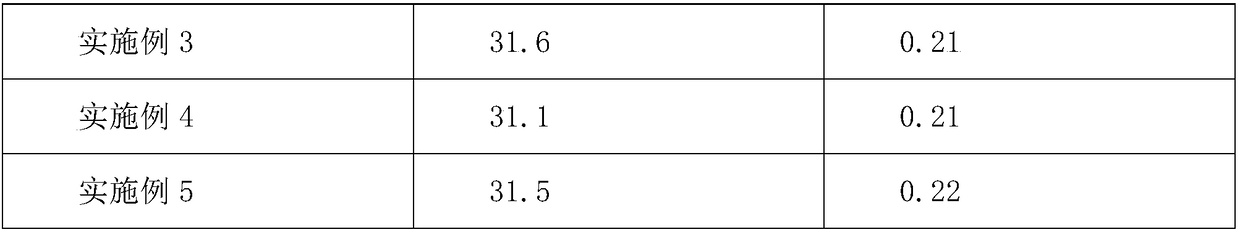

Examples

Embodiment 1

[0023] In the embodiment of the present invention, a flame-retardant plastic includes the following raw materials in parts by weight: 80 parts of polyethylene, 8 parts of polypropylene, 10 parts of polyphenylene sulfide, 6 parts of modified mica powder, and 10 parts of modified calcium carbonate , 12 parts of montmorillonite, 6 parts of diatomite, 0.2 part of coupling agent, 10 parts of toughening agent, 0.1 part of ultraviolet absorber, 2 parts of sodium phytate, and 0.5 part of flame retardant.

[0024] Wherein, the preparation method of the modified mica powder is as follows: the mica powder is roasted at a temperature of 400° C. for 2 hours, and the mica powder after roasting is mixed with γ-aminopropyltriethoxysilane according to a mass ratio of 20:1. , add 8 times of water and ultrasonically disperse for 20min, the ultrasonic frequency is 40KHz, and the ultrasonic power is 200W to obtain a mixed solution A, add its total mass of 0.1% zinc borate and 0.2% ammonium polyphos...

Embodiment 2

[0036] In the embodiment of the present invention, a flame-retardant plastic includes the following raw materials in parts by weight: 85 parts of polyethylene, 9 parts of polypropylene, 12 parts of polyphenylene sulfide, 7 parts of modified mica powder, and 11 parts of modified calcium carbonate , 13 parts of montmorillonite, 7 parts of diatomite, 0.4 part of coupling agent, 12 parts of toughening agent, 0.2 part of ultraviolet absorber, 3 parts of sodium phytate, and 1 part of flame retardant.

[0037] Wherein, the preparation method of the modified mica powder is as follows: the mica powder is roasted at a temperature of 450° C. for 3 hours, and the mica powder after roasting is mixed with γ-aminopropyltriethoxysilane according to a mass ratio of 20:1. , add 9 times of water and ultrasonically disperse for 20min, the ultrasonic frequency is 40KHz, and the ultrasonic power is 250W to obtain a mixed solution A, add its total mass of 0.1% zinc borate and 0.2% ammonium polyphosph...

Embodiment 3

[0049] In the embodiment of the present invention, a flame-retardant plastic includes the following raw materials in parts by weight: 90 parts of polyethylene, 10 parts of polypropylene, 15 parts of polyphenylene sulfide, 9 parts of modified mica powder, and 12 parts of modified calcium carbonate , 14 parts of montmorillonite, 8 parts of diatomite, 0.5 parts of coupling agent, 14 parts of toughening agent, 0.3 parts of ultraviolet absorber, 4 parts of sodium phytate, and 1.5 parts of flame retardant.

[0050] Wherein, the preparation method of the modified mica powder is as follows: the mica powder is roasted at a temperature of 450° C. for 4 hours, and the mica powder after roasting is mixed with γ-aminopropyltriethoxysilane according to a mass ratio of 20:1. , add 9 times of water and ultrasonically disperse for 25min, the ultrasonic frequency is 45KHz, and the ultrasonic power is 300W to obtain a mixed solution A, add its total mass of 0.2% zinc borate and 0.3% ammonium poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com