Pipe body flat clamp for spacing, limiting, fixing and clamping pipe body

A technology for limiting and fixing pipes, which is applied in the direction of pipes/pipe joints/fittings, pipe supports, mechanical equipment, etc., to achieve the effects of high mechanical strength, uniform force, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

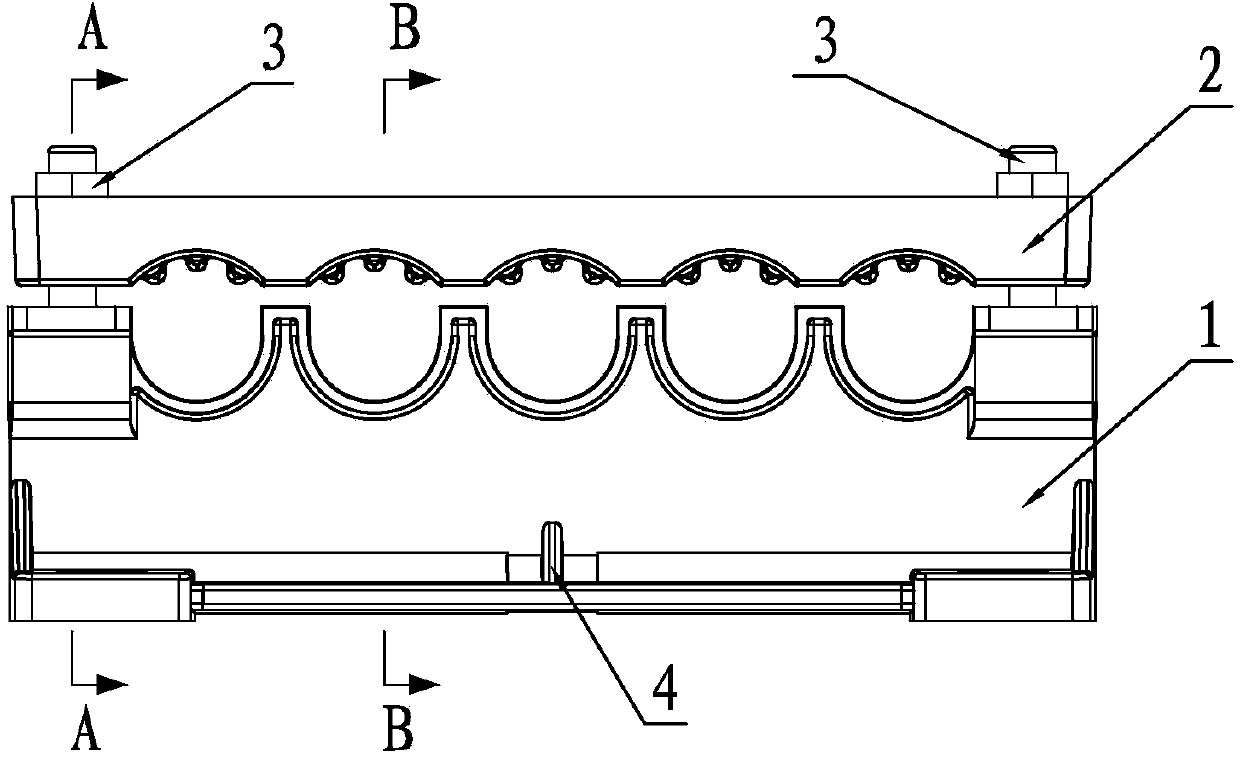

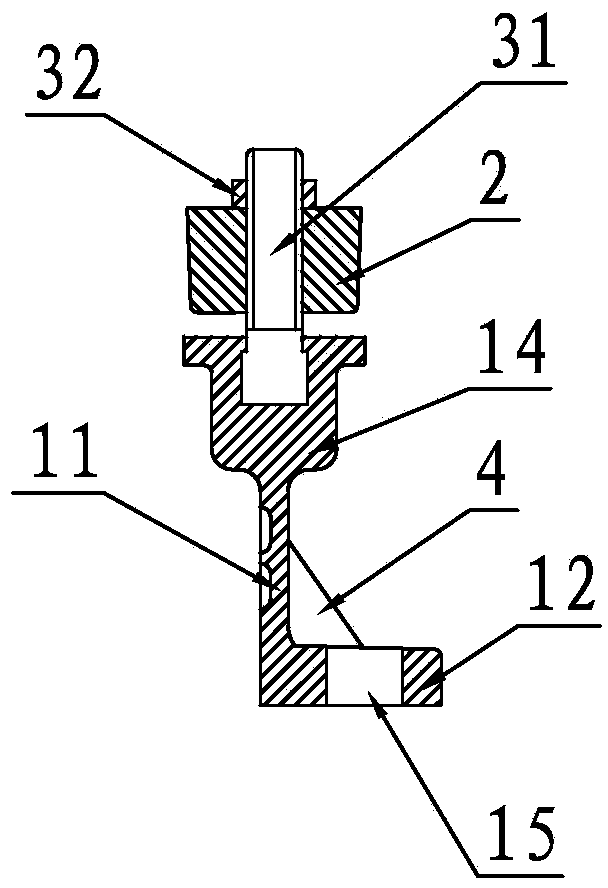

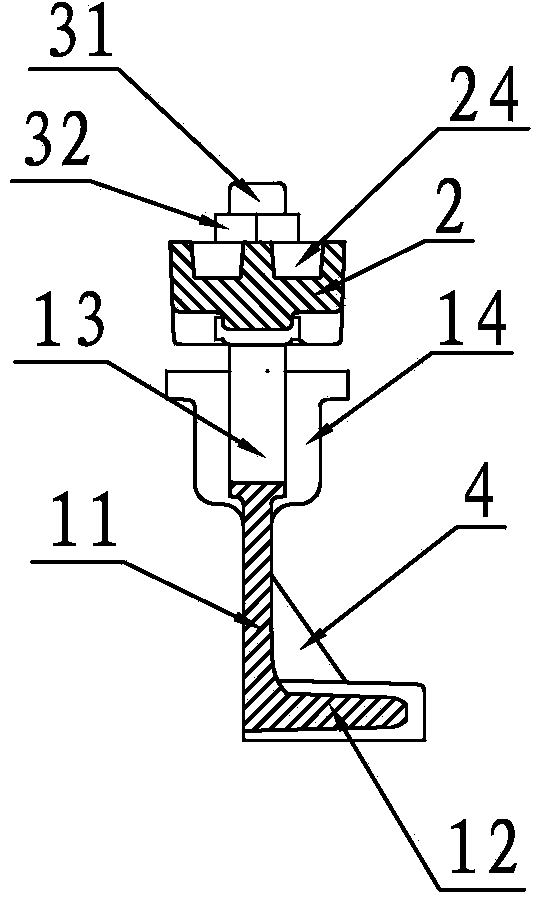

[0031] Embodiment 1: A kind of pipe body clamping that is fixedly clamped at intervals between pipe bodies, such as Figure 1 to Figure 5As shown, it includes a tube clip 1, a tube body pressure plate 2, a fixing screw 31 and a nut 32. The tube clip 1 is composed of a spacer web 11 and a fixed bottom plate 12, and is spaced along the length direction on the spacer web 11. There are five U-shaped limiting grooves 13 for accommodating gas pipes, and fixing seats 14 are provided at both ends of the spacer web 11, and fixed screws 31 are inlaid on the fixing seats 14, and the fixed bottom plate 12 is arranged on the spacer web. 11, the installation bottom surface of the fixed base plate 12 is parallel to the axis of the limit groove 13, the angle between the spacer web plate 11 and the fixed base plate 12 is 90°, and there are fixed holes 15 at both ends of the fixed base plate 12. In order to fix the tube holder 1 on the wall, there is a water outlet hole 16 in the middle of the ...

Embodiment 2

[0032] Embodiment 2: A pipe body clamping arrangement for fixed clamping of the pipe body at intervals, including a pipe clamp seat 1, a pipe body pressure plate 2, a fixing screw 31 and a nut 32, and the tube clamp seat 1 is composed of a tube spacer web 11 Composed of a fixed bottom plate 12, ten U-shaped limiting grooves 13 for accommodating gas pipes are arranged at intervals along the length direction on the spacer web 11, and at both ends of the spacer web 11 and the fifth and sixth limit slots There is a fixed seat 14 between the grooves 13, and a fixed screw 31 is inlaid on the fixed seat 14. The angle between the spacer web 11 and the fixed bottom plate 12 is 90°. On the fixed bottom plate 12, three Fixing holes 15, one at each end and one in the middle, are used to fix the tube holder 1 on the wall, and there are three water outlet holes 16 at equal intervals at the junction of the spacer panel 11 and the fixed bottom plate 12, for timely drainage. Rainwater; ten arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com