Antibacterial antistatic enhanced polycarbonate (PC) material and preparation method thereof

A polycarbonate and reinforced technology, which is applied in the field of antibacterial and antistatic reinforced polycarbonate materials and their preparation, can solve the antibacterial problems of less polycarbonate materials, and achieve the advantages of reduced usage, excellent physical properties, and excellent physical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

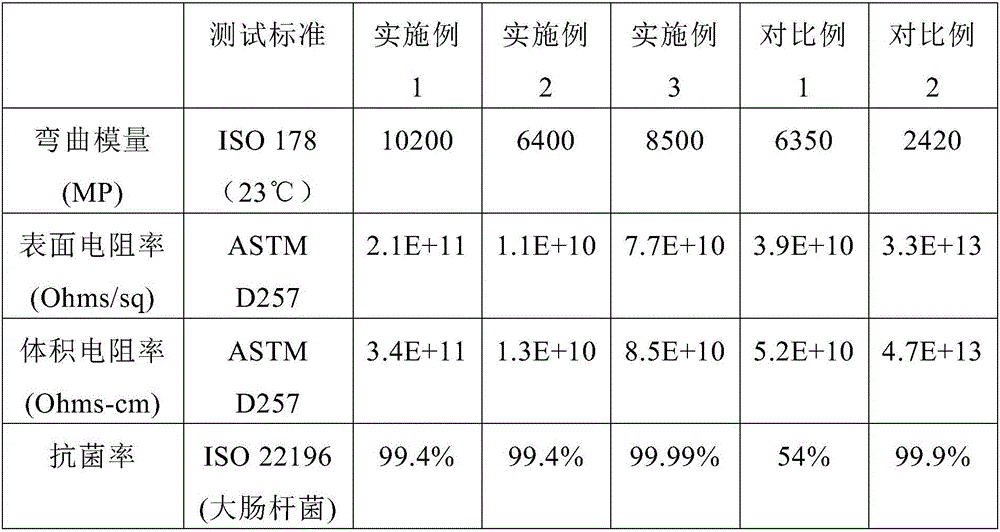

Examples

Embodiment 4

[0032] The raw materials used are,

[0033] PC resin: Asahi Kasei's L-1250Y, with a relative molecular weight of 15,000 and a glass transition temperature of 140°C, 70kg;

[0034] Carbon fiber: 4mm chopped carbon fiber sheet with a bulk density of 400g / L, 5kg;

[0035] Antibacterial agent: zeolite-based antibacterial agent containing silver ions; 5kg;

[0036] Flame retardant: decabromodiphenyl ether, 0.5kg;

[0037] Also added a small amount of lubricants, antioxidants, anti-ultraviolet aging agents and fillers;

[0038] The specific preparation method is to prepare materials according to the formula, add PC resin, antibacterial agent, flame retardant, lubricant, antioxidant, anti-ultraviolet aging agent and filler to a mixing mixer for mixing, and pass the obtained mixture through a twin-screw extruder Add the carbon fiber from the side feeding port of the twin-screw extruder, blend and melt, extrude and granulate to obtain the product. The barrel temperature of the twin-...

Embodiment 5

[0040] The raw materials used are,

[0041] PC resin: relative molecular weight is 30000, glass transition temperature is 150℃, 90kg;

[0042] Carbon fiber: 12mm chopped carbon fiber sheet, bulk density 600g / L, 20kg;

[0043] Antibacterial agent: zeolite-based antibacterial agent containing silver ions, 10kg;

[0044] Flame retardant: brominated styrene, 1kg;

[0045] The specific preparation method is to prepare materials according to the formula, add PC resin, antibacterial agent and flame retardant to the mixing mixer for mixing; add the obtained mixture through the main feeding port of the twin-screw extruder, and extrude the carbon fiber from the twin-screw extruder The side feed port of the extruder is added, blended and melted, extruded and granulated to obtain the product. The barrel temperature of the twin-screw extruder is 280° C., the screw speed is 600 rpm, and the pressure is 2.5 MPa.

Embodiment 6

[0047] The raw materials used are,

[0048] PC resin: relative molecular weight is 20000, glass transition temperature is 145℃, 80kg;

[0049] Carbon fiber: 8mm chopped carbon fiber sheet with a bulk density of 500g / L, 10kg;

[0050] Antibacterial agent: TiO 2 Photocatalytic antibacterial agent, 7kg;

[0051] Flame retardant: brominated epoxy, 0.8kg;

[0052] The specific preparation method is to prepare materials according to the formula, add PC resin, antibacterial agent and flame retardant to the mixing mixer for mixing; add the obtained mixture through the main feeding port of the twin-screw extruder, and extrude the carbon fiber from the twin-screw extruder The side feed port of the extruder is added, blended and melted, extruded and granulated to obtain the product. The temperature of the barrel of the twin-screw extruder is 260 ° C, the screw speed is 400 rpm, and the pressure is 2 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com