Preparation method of anti-ultraviolet antistatic anti-pilling polyester chip

A technology of polyester chips and anti-ultraviolet, which is applied in the direction of single-component polyester artificial filaments, etc., can solve the problems of anti-ultraviolet effect to be improved, poor anti-ultraviolet performance, easy pilling, etc., to achieve improved anti-ultraviolet performance, excellent Antistatic properties, effect of reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

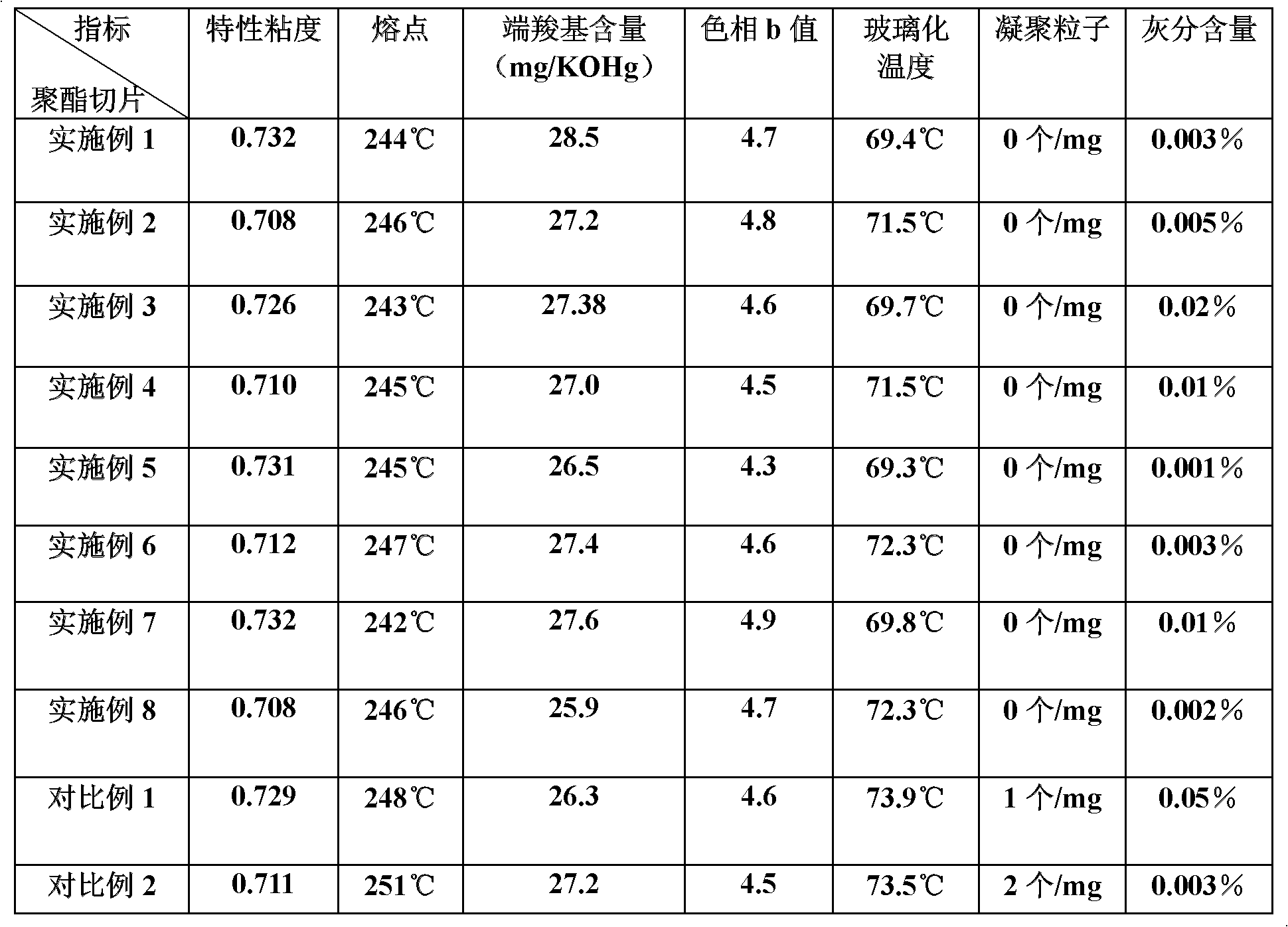

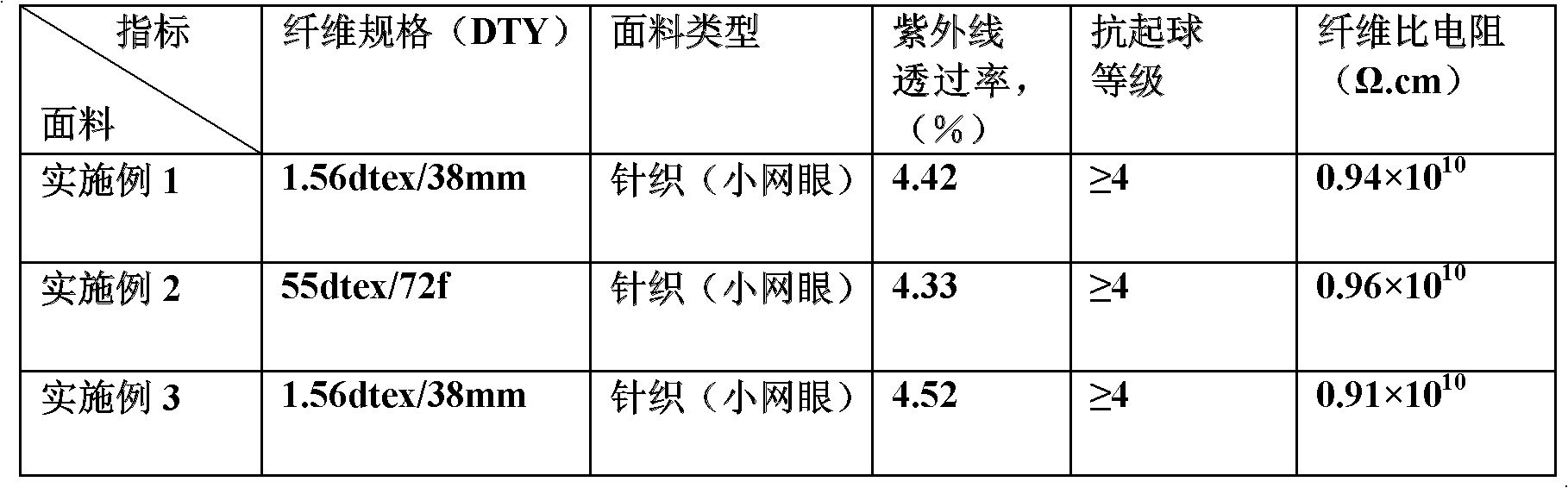

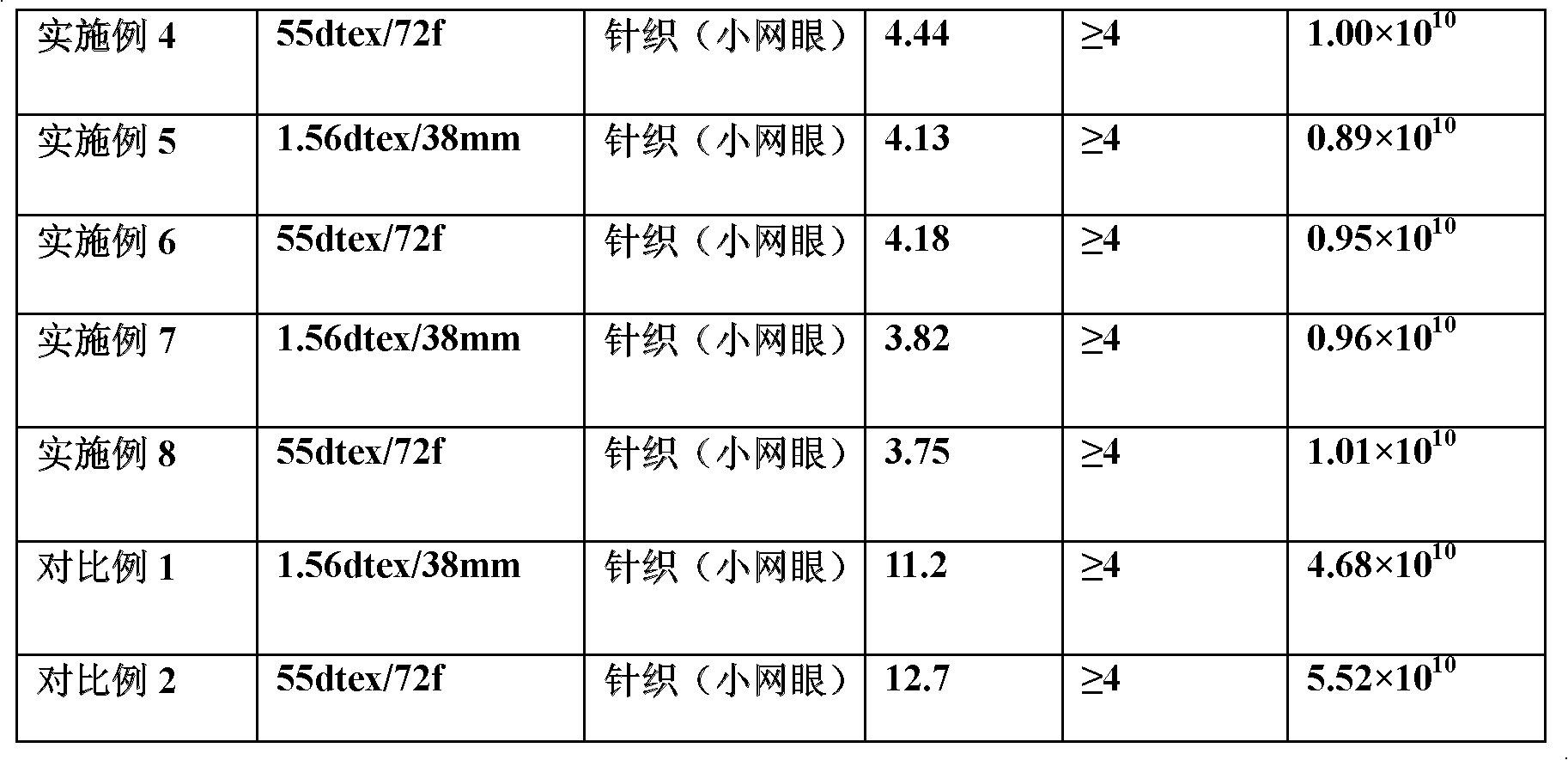

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing an anti-ultraviolet, anti-static, anti-pilling polyester chip, which includes the following steps:

[0035] (1), primary esterification reaction section: take 18kg of purified terephthalic acid (PTA), 7.5kg of ethylene glycol (EG) and add 70 liters of polyester experimental equipment, after stirring evenly, start to heat up and pressurize to 0.3Mpa, Esterification is carried out, and the esterification temperature is controlled at 250-265°C. After the esterification is completed, the water is discharged, and the normal pressure is returned to complete the reaction.

[0036] (2) Secondary esterification reaction section: After the primary esterification is completed, ethylene glycol is first added to lower the temperature of the reactor to 230-235°C, and then 450g of polyethylene glycol with a number average molecular weight of 2500 that has been heated and melted is added The diol was added into the reactor under the prote...

Embodiment 2

[0039] This embodiment provides a method for preparing an anti-ultraviolet, anti-static, anti-pilling polyester chip, which includes the following steps:

[0040](1), primary esterification reaction section: take 18kg of purified terephthalic acid (PTA), 7.5kg of ethylene glycol (EG) and add 70 liters of polyester experimental equipment, after stirring evenly, start to heat up and pressurize to 0.3Mpa, Esterification is carried out, and the esterification temperature is controlled at 250-265°C. After the esterification is completed, the water is discharged, and the normal pressure is returned to complete the reaction.

[0041] (2) Secondary esterification reaction section: After the primary esterification is completed, ethylene glycol is first added to lower the temperature of the reactor to 230-235°C, and then 450g of polyethylene glycol with a number average molecular weight of 2500 that has been heated and melted The diol was added into the reactor under the protection of n...

Embodiment 3

[0044] This embodiment provides a method for preparing an anti-ultraviolet, anti-static, anti-pilling polyester chip, which includes the following steps:

[0045] (1), primary esterification reaction section: take 18kg of purified terephthalic acid (PTA), 7.5kg of ethylene glycol (EG) and add 70 liters of polyester experimental equipment, after stirring evenly, start to heat up and pressurize to 0.3Mpa, Esterification is carried out, and the esterification temperature is controlled at 250-265°C. After the esterification is completed, the water is discharged, and the normal pressure is returned to complete the reaction.

[0046] (2) Secondary esterification reaction section: After the primary esterification is completed, ethylene glycol is first added to lower the temperature of the reactor to 230-235°C, and then 450g of polyethylene glycol with a number average molecular weight of 3000 that has been heated and melted is added The diol was added into the reactor under the prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com