GaN-based light emitting diode epitaxial structure

A technology of light-emitting diodes and epitaxial structures, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the conduction band step, increasing hole injection blocking, weakening electron blocking, etc., to improve radiation recombination efficiency, The effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

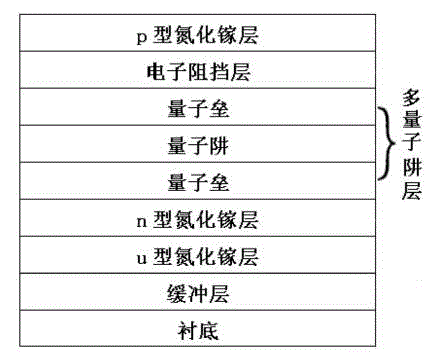

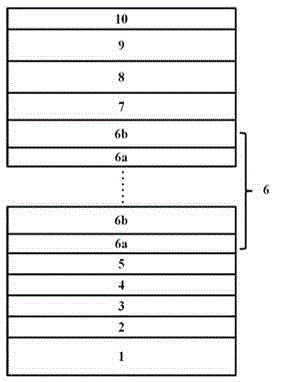

[0026] Schematic diagram of the epitaxial structure of the GaN-based LED in this embodiment, as shown in figure 2 As shown, including silicon substrate 1; AlN / Al 0.5 Ga 0.5 N / Al 0.2 Ga 0.8 N / Al 0.05 Ga 0.95 Stress control layer 2 of N four-layer structure; n-type GaN layer 3, wherein n-type GaN layer 3 includes a layer of 500nm unintentionally doped GaN layer and a layer of 3mm silicon-doped n-GaN layer, n- The doping concentration of GaN is 8×10 18 cm -3 ; n-type doped Al 0.1 Ga 0.9 N current spreading layer 4, wherein the thickness of the current spreading layer 4 is 60nm, and the doping concentration is 5×10 18 cm -3 ; Silicon doping concentration is 2×10 17 cm -3 , a thickness of 50 nm of In 0.02 Ga 0.98 N stress buffer layer 5; multi-quantum well active layer 6, whose alternating period is 6 narrow bandgap In 0.15 Ga 0.85GaN quantum barrier 6b of N quantum well 6a and wide bandgap, the thickness of quantum well / barrier is respectively 3nm / 12nm; Spacer la...

Embodiment 2

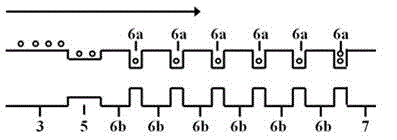

[0031] Schematic diagram of the epitaxial structure of the GaN-based LED in this embodiment, as shown in figure 2 As shown, it includes a sapphire substrate 1; the stress control layer 2 is an undoped GaN layer; the thickness of the n-type GaN layer 3 is 3um, and the doping concentration is 2×10 19 cm -3 ; The current spreading layer 4 is an alternately deposited AlGaN / InGaN superlattice structure, and an Al with a thickness of 10 nm is deposited at intervals on the n-type GaN layer 3 0.05 Ga 0.95 N layer 4b and In with a thickness of 5 nm 0.05 Ga 0.95 N layer 4a, such as Figure 5 shown, where Al 0.05 Ga 0.95 N doping concentration is 1×10 19 cm -3 , In 0.05 Ga 0.95 No doping in N; the stress buffer layer 5 is an alternately grown undoped InGaN / GaN (2nm / 5nm) superlattice, where the In composition in InGaN is 10%; the multi-quantum well active layer 6 is alternately grown 15 pairs of narrow bandgap In 0.15 Ga 0.85 GaN quantum barrier 6b of N quantum well 6a and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com