Nitride light-emitting diode

A technology of light-emitting diodes and nitrides, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of high operating voltage of light-emitting diodes, large contact resistance between the P-type contact layer and the current spreading layer, and low activation efficiency of P-type impurities , to achieve the effect of improving horizontal expansion capability, reducing operating voltage, and improving antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

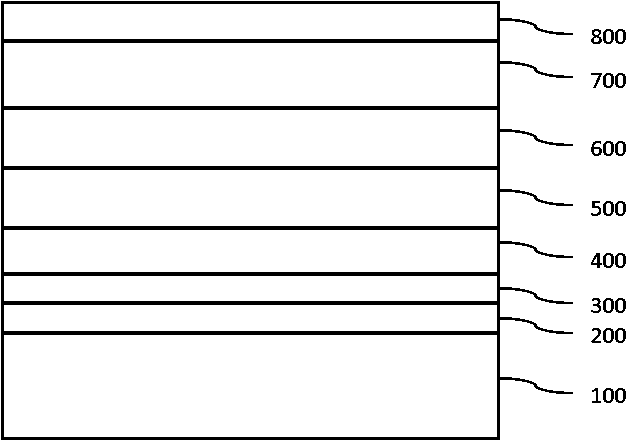

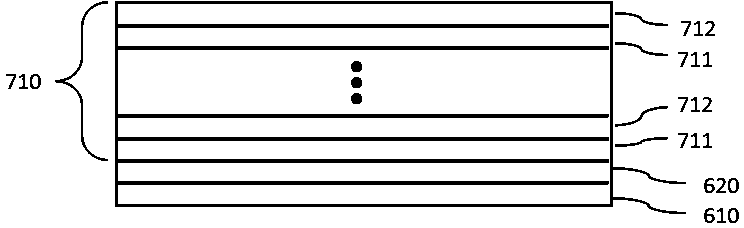

[0023] See attached figure 1 , the present invention discloses a nitride light-emitting diode, including a substrate 100, and a nucleation layer 200, a buffer layer 300, an n-type layer 400, a light-emitting layer 500, a P-type layer 600, and an N-type layer sequentially located on the substrate 100. The contact layer 700 and the current spreading layer 800 .

[0024] Traditional LEDs use Mg-doped GaN layer as the P contact layer, but the contact layer formed by the combination of Mg-doped GaN layer and current spreading layer (such as ITO) is a non-ohmic contact, and its current spreading effect is poor, making the operation of the LED High voltage, poor antistatic ability.

[0025] In the present invention, the N-type contact layer 700 is used to replace the traditional P-type contact layer. The contact layer formed in combination with the current spreading layer is an ohmic contact, and its current spreading effect is better, which reduces the risk of device breakdown due ...

Embodiment 2

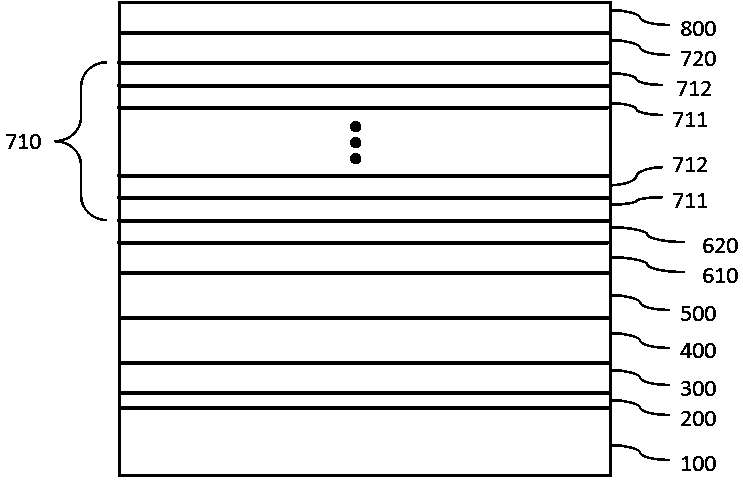

[0035] See attached image 3 , The difference between this embodiment and Embodiment 1 is that in order to further improve the contact resistance between the N-type contact layer 700 and the current spreading layer 800 on it, and the ability to expand the injection current, the u-GaN / n-GaN superlattice structure An n+ GaN layer 720 is added on the surface of the layer 710, and the n-type impurity concentration of the n+ GaN layer 720 is not less than the n-type impurity concentration in the u-GaN / n-GaN superlattice structure layer 710, and the n-type impurity concentration in the n+GaN layer 720 1×10 19 ~5×10 19 / cm 3 , the thickness of the n+ GaN layer 720 is 10Ř250Å.

[0036] Therefore, the nitride light-emitting diode proposed in this embodiment includes a substrate 100, a nucleation layer 200, a buffer layer 300, an n-type layer 400, a light-emitting layer 500, a low-temperature p-type GaN layer 610, and a substrate 100 sequentially located on the substrate 100. The p...

Embodiment 3

[0038] See attached Figure 4 , the difference between this embodiment and Embodiment 1 or 2 is: etching part of the current spreading layer 800, the N-type contact layer 700, the P-type layer 600 and the light-emitting layer 500 to the n-type layer 400 to form an n-type platform, and connect with the n-type An N electrode 410 is arranged on the platform, and a P electrode 810 is arranged on the current spreading layer 800 . When a current is injected, the electrons provided by the n-type layer 400 and the holes provided by the p-type layer 600 recombine in the light-emitting layer to emit light of a certain wavelength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com