Adhesive composition

A technology of pressure-sensitive adhesives and compositions, applied in the direction of adhesive types, ester copolymer adhesives, grafted polymer adhesives, etc., which can solve problems such as pollution, reduced strength, and difficulty in suppressing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

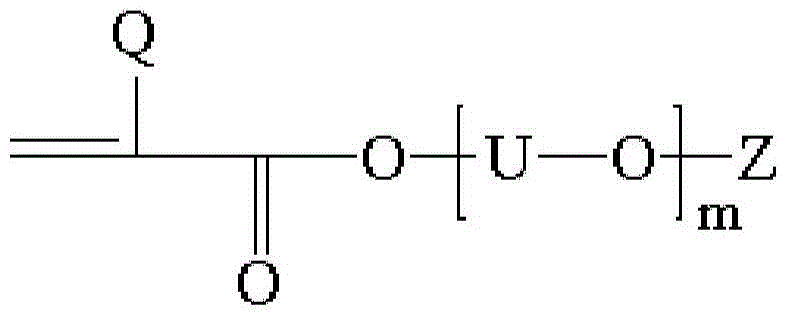

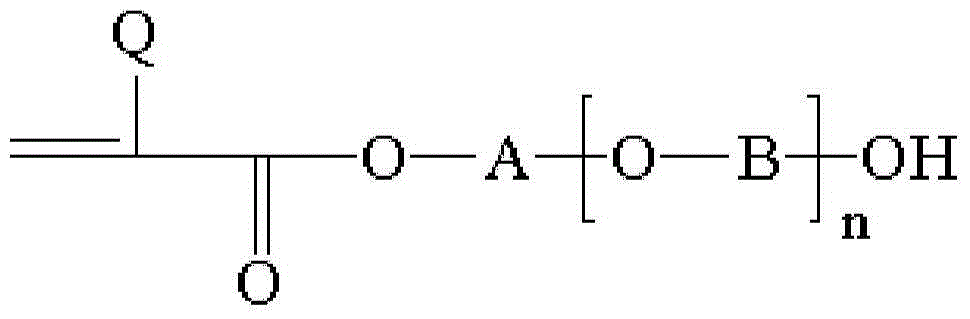

[0158] Preparation Example 1: Preparation of Acrylic (Ester) Polymer (A)

[0159] 85 parts by weight of 2-ethylhexyl acrylate (2-EHA), 2 parts by weight of 4-hydroxybutyl acrylate (4-HBA), 5 parts by weight of 2-hydroxyethyl acrylate (2-HEA), 3 parts by weight of dimethylacrylamide and 5 parts by weight of polyethylene glycol monomethyl ether methacrylate (the number of moles added to the ethylene oxide unit: 9 mol) were added to a machine equipped with nitrogen reflux and easy to control temperature. The 1 L reactor of the apparatus was cooled, and then 100 parts by weight of ethyl acetate was added as a solvent. Subsequently, nitrogen was purged for 1 hour to remove oxygen, a reaction initiator (AIBN: azobisisobutyronitrile) was added to react for about 8 hours, and the reaction product was diluted with ethyl acetate. Thereby, an acrylic (ester) type polymer (A) was prepared.

preparation example 2 to 12

[0160] Preparation Examples 2 to 12: Preparation of Acrylic (Ester) Polymers B to L

[0161] An acrylic (ester) polymer was prepared in the same manner as described in Preparation Example 1, except that the proportion of monomers used to prepare the polymer was changed as shown in Table 1 and Table 2.

[0162] [Table 1]

[0163]

[0164] [Table 2]

[0165]

Embodiment 1

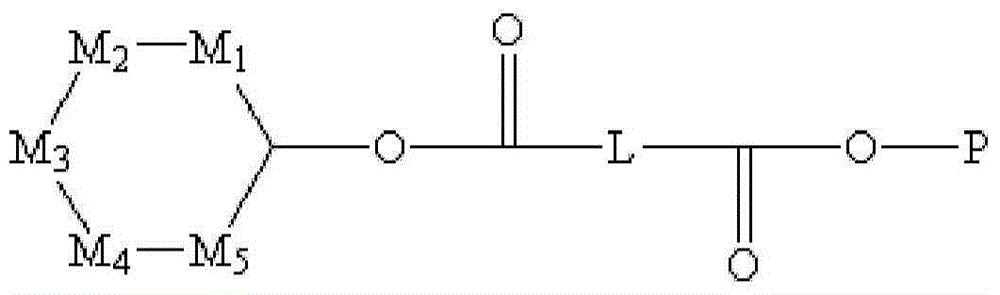

[0167] Preparation of pressure sensitive adhesive composition

[0168] A pressure-sensitive adhesive composition is prepared by uniformly mixing 5.0 parts by weight of isophorone diisocyanate-based A mixture of crosslinking agent and hexamethylene diisocyanate-based crosslinking agent (MHG-80B, Asahi Chemical Company (AKCC)) and 0.5 parts by weight of lithium bis(trifluoromethanesulfonyl)imide (LiTFSi ), and dilute the resulting mixture to an appropriate concentration in consideration of the coating properties.

[0169] Preparation of pressure sensitive adhesive sheets

[0170] By coating the prepared pressure-sensitive adhesive composition on one surface of a poly(ethylene terephthalate) (PET) film (thickness: 38 μm) and drying, a uniform coating was formed to have a thickness of about 20 μm. . Subsequently, the coating was kept at about 90° C. for 3 minutes to initiate a crosslinking reaction, thereby preparing a pressure-sensitive adhesive sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com