Liquid crystal display device

A liquid crystal display device and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as panel defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

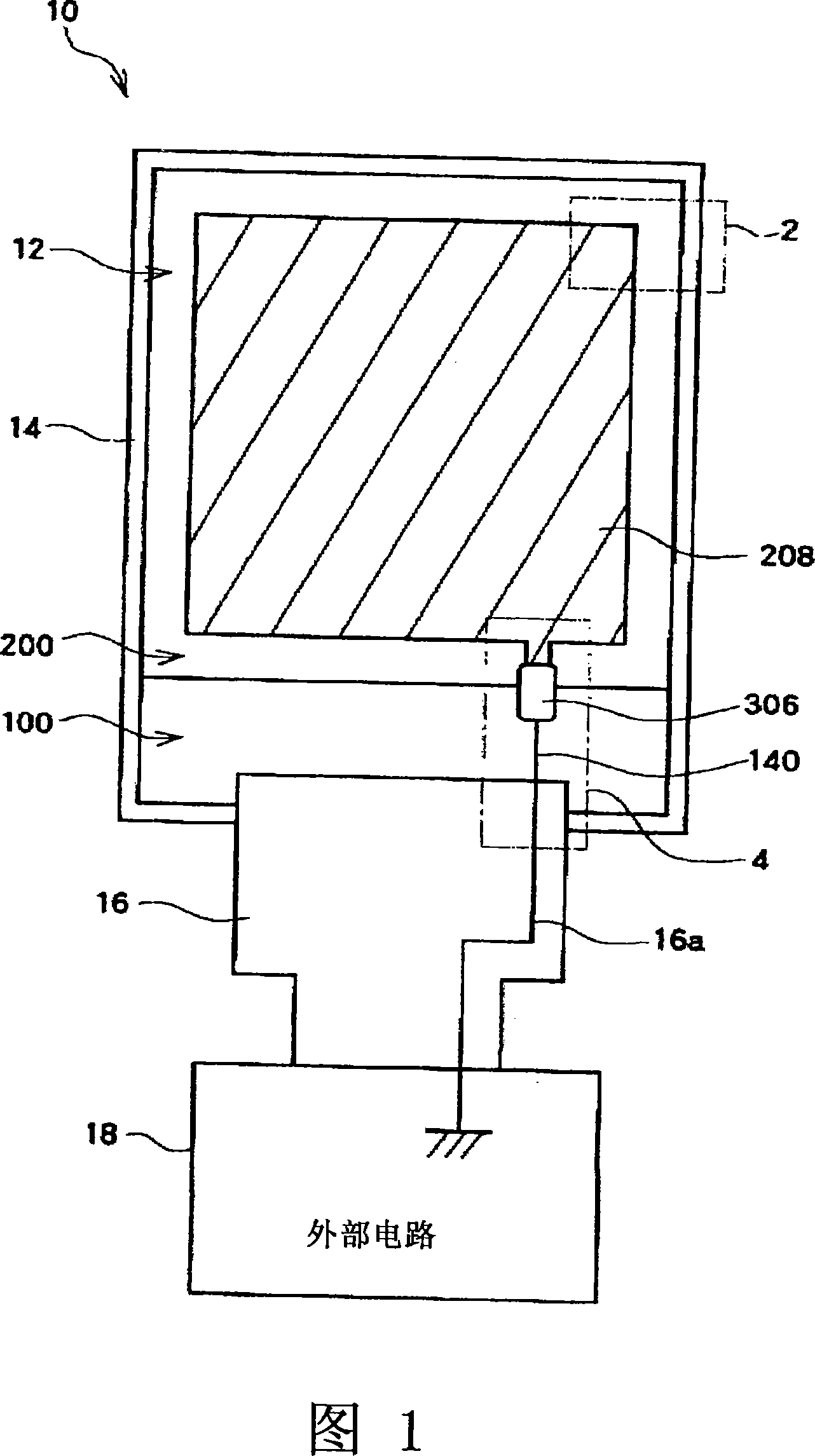

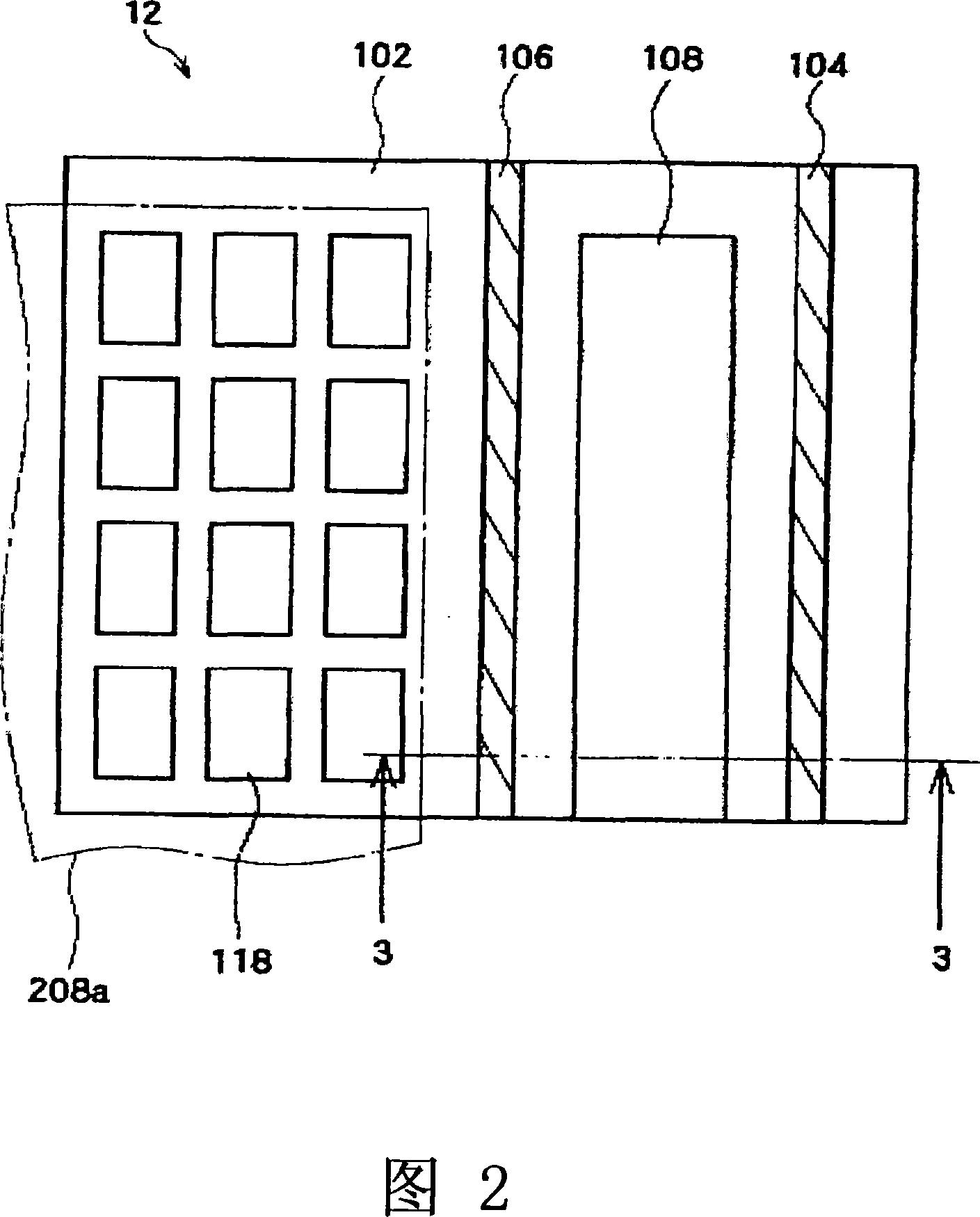

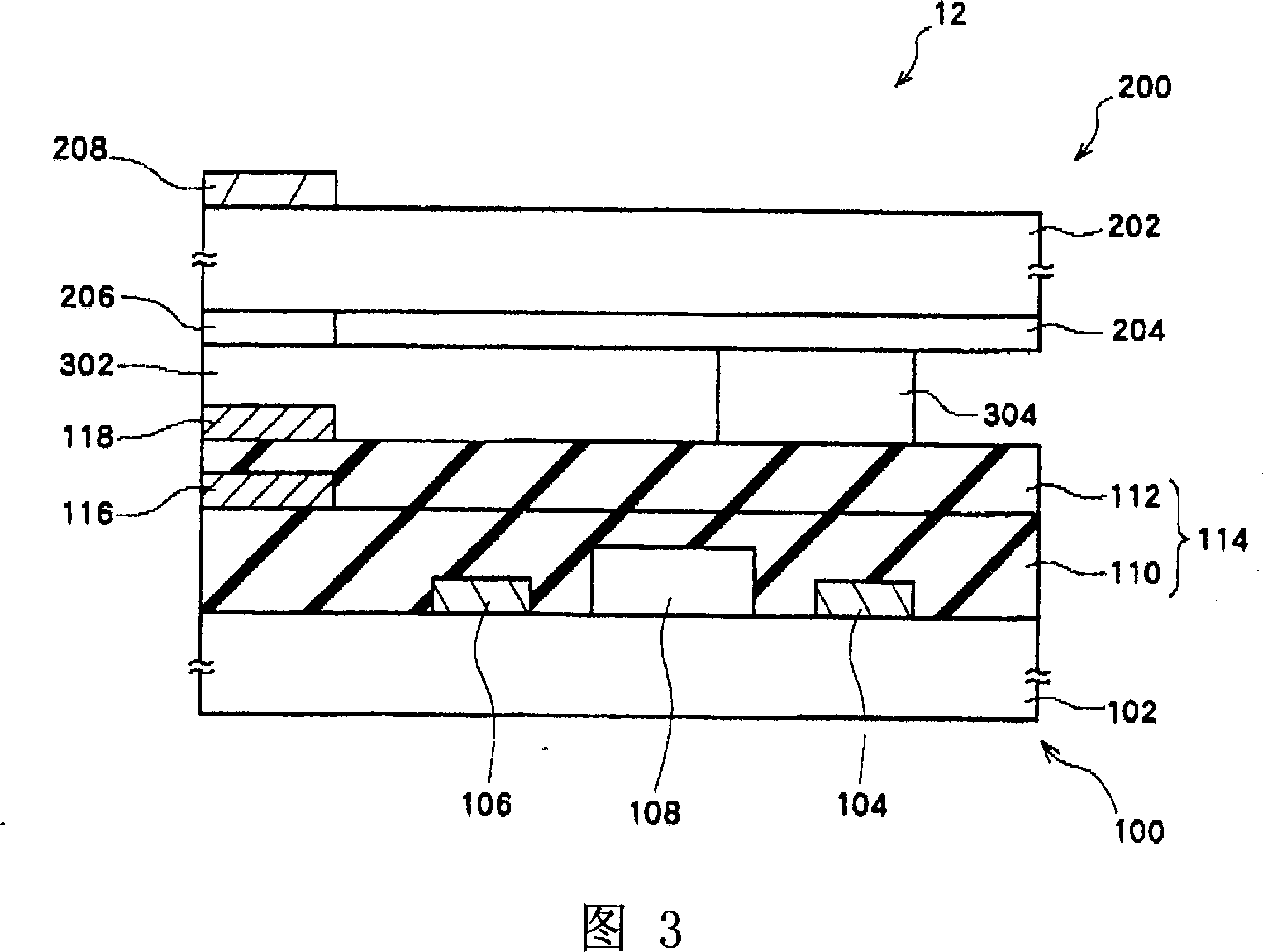

[0046] Before describing the embodiments of the present invention, various evaluations of the electrostatic withstand voltage characteristics have been considered. Therefore, for the antistatic characteristics considered, refer to the cross-sections near the peripheral portion of the liquid crystal display device shown in FIGS. 11 and 12. Figure to illustrate.

[0047] As shown in FIG. 11 and FIG. 12 , in the conventional liquid crystal display device 10Z in the FFS mode, the first substrate 100Z and the second substrate 200Z are bonded by a sealant 304Z, and these substrates 100Z, A liquid crystal 302Z is sandwiched between 200Z. A circuit wiring group 104Z is arranged on a support substrate 102Z of the first substrate 100Z, and an insulating film 114Z is arranged to cover the circuit wiring group 104Z. In addition, in drawing, the circuit wiring group 104Z is shown schematically. On the outer surface of the supporting substrate 202Z of the second substrate 200Z, a light-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com