Microcellular foam film-coated packaging paper material and preparation method thereof

A packaging paper and micro-foaming technology, applied in the field of materials, can solve the problems of poor gas barrier properties, poor heat resistance, poor oil resistance, etc., and achieve good foaming effect, excellent barrier properties, and good convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

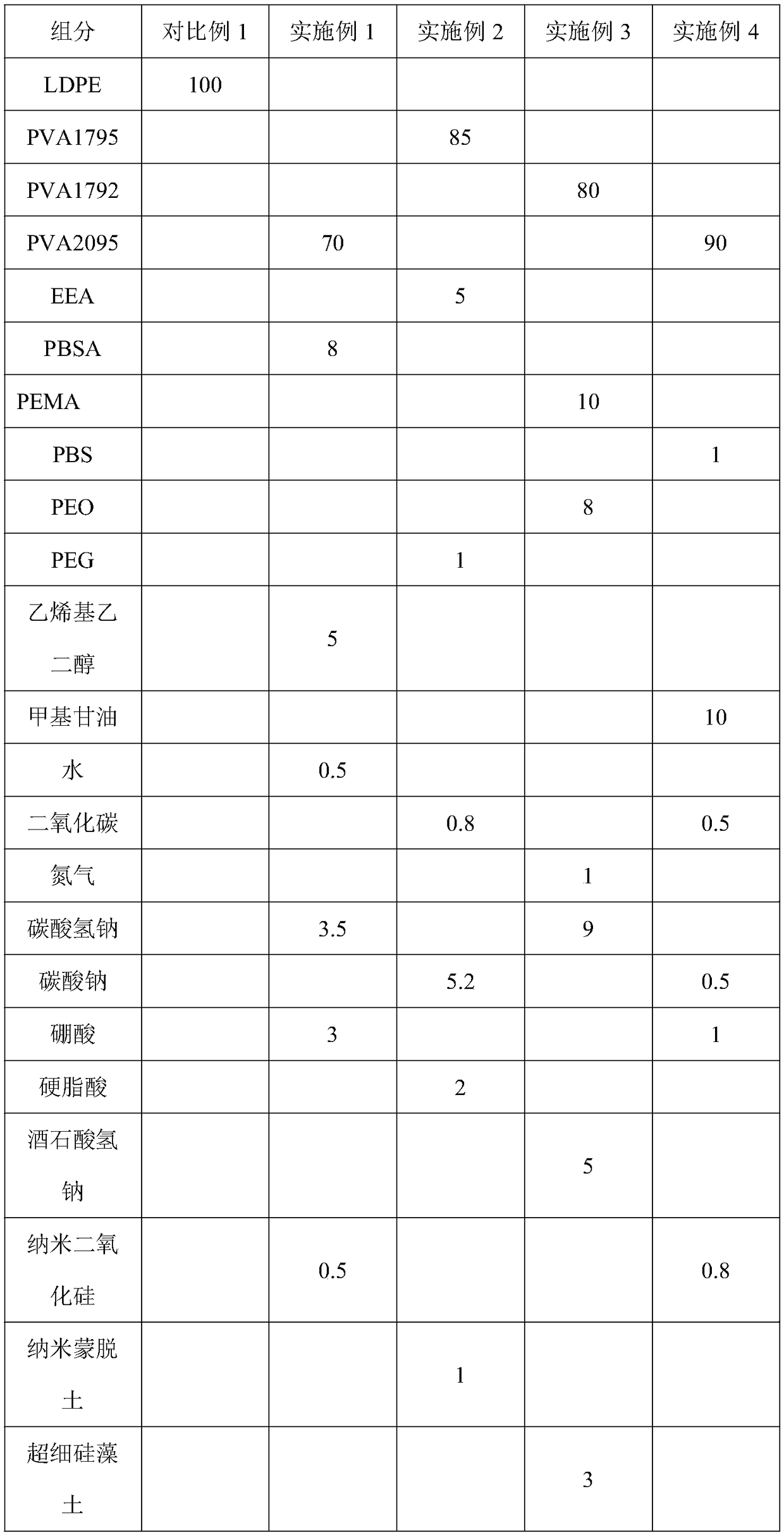

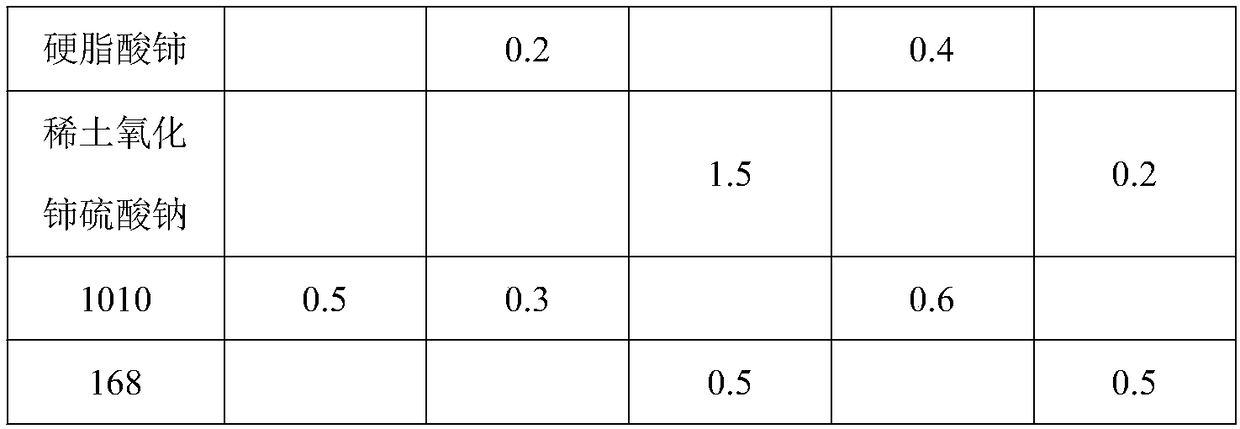

Embodiment 1

[0031] Step 1: Pre-mix 85 parts of polyvinyl alcohol PVA2095 and 8 parts of flow modifier PBSA in a high-speed mixer according to the parts by weight, and then put the mixture in the reactor and let it stand for 0.5 hours. Then, with 5 parts of melt reinforcing agent vinyl glycol, 0.5 part of anti-blocking agent nano-silica, 3.5 parts of endothermic chemical foaming agent sodium bicarbonate, 3 parts of foaming aid boric acid, 0.2 parts of other additives cerium stearate and 0.3 parts of antioxidant 1010 were mixed in a medium-speed mixer according to parts by weight for 2 minutes to obtain a mixture;

[0032] Step 2: Add the mixture obtained from the mixer in Step 1 into the single-screw film extruder through the hopper, and add 0.5 parts of physical foaming agent water into the extruder through the air inlet at the top of the barrel according to the number of parts by weight. At a temperature of 130-200°C, extrusion casting is carried out to form a foamed polyvinyl alcohol fi...

Embodiment 2

[0036] Step 1: Pre-mix 85 parts of polyvinyl alcohol PVA1795 and 8 parts of flow modifier EEA in a high-speed mixer according to the parts by weight, and then put the mixture in the reactor for 1 hour. Then, mix the above mixture with 5 parts of melt reinforcing agent PEG, 1 part of anti-blocking agent nano-montmorillonite, 5.2 parts of endothermic chemical foaming agent sodium carbonate, 2 parts of foaming aid stearic acid, and other additives 1.5 parts of stabilizer rare earth cerium oxide sodium sulfate and 0.5 parts of antioxidant 168 were mixed in a medium-speed mixer for 4 minutes according to parts by weight to obtain a mixture;

[0037] Step 2: Add the mixture obtained from the mixer in Step 1 into the single-screw film extruder through the hopper, and add 0.8 parts of physical foaming agent carbon dioxide into the extruder through the air inlet on the top of the barrel according to the number of parts by weight. At a temperature of 130-200°C, extrusion casting is carr...

Embodiment 3

[0041] Step 1: 80 parts of polyvinyl alcohol PVA1792 and 10 parts of flow modifier PEMA were pre-mixed in a high-speed mixer for 1.5 minutes according to parts by weight, and then the mixture was placed in a reactor and left to stand for 0.8 hours. Then, mix the above mixture with 8 parts of melt reinforcing agent PEO, 3 parts of anti-blocking agent superfine diatomite, 9 parts of endothermic chemical foaming agent sodium bicarbonate, 5 parts of foaming aid sodium hydrogen tartrate, and other additives. 0.4 part of stabilizer cerium stearate and 0.6 part of antioxidant 1010 were mixed in a medium-speed mixer for 3 minutes according to parts by weight to obtain a mixture;

[0042] Step 2: Add the mixture obtained from the mixer in Step 1 into the single-screw film extruder through the hopper, and add 1 part of the physical foaming agent nitrogen into the extruder through the air inlet at the top of the barrel according to the weight parts. At a temperature of 130-200°C, extrusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com