Packing box for transporting glass base plate

A technology of glass substrates and packaging boxes, applied in the direction of transportation and packaging, packaging of vulnerable items, types of packaging items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

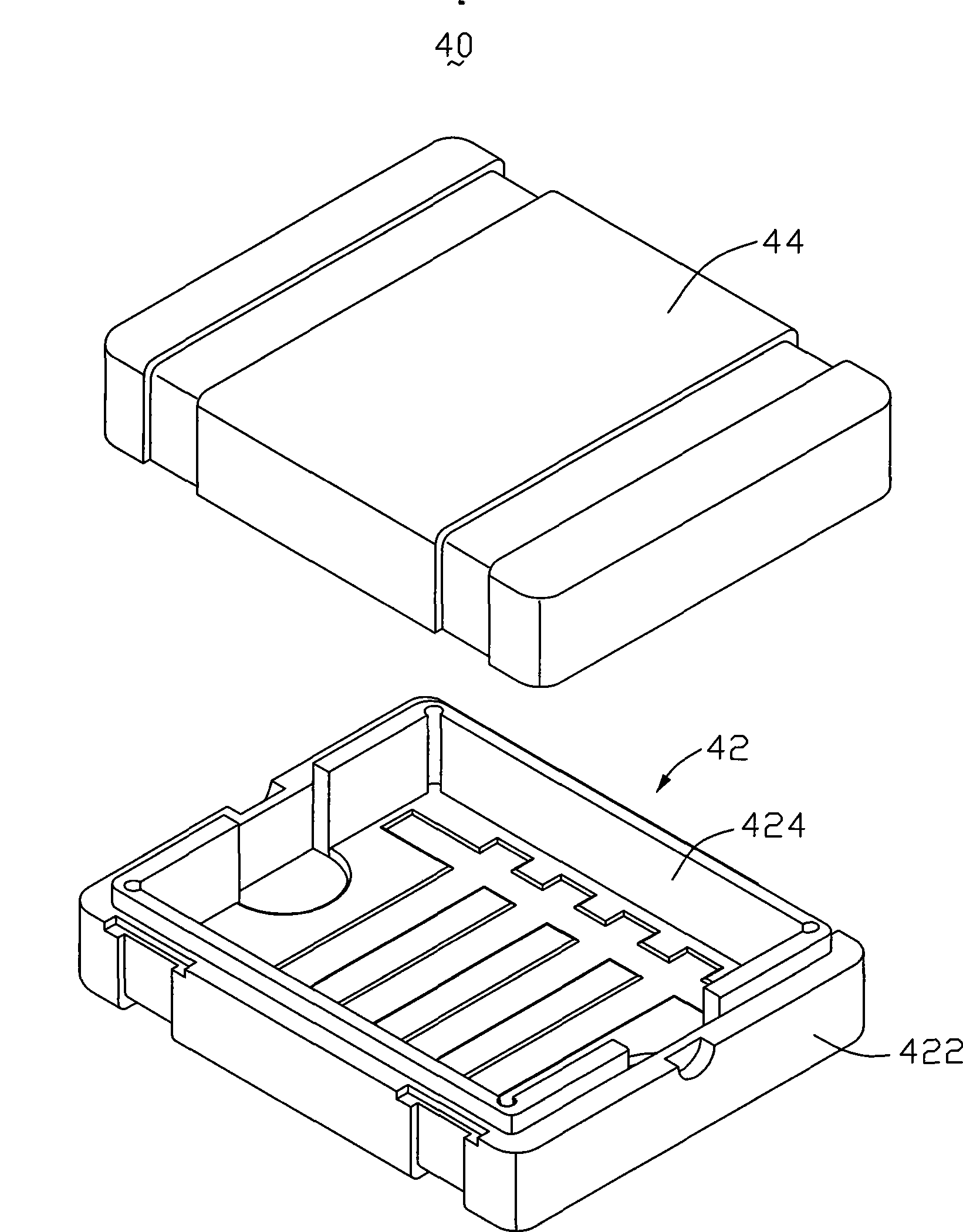

[0027] see image 3 , is a three-dimensional exploded schematic view of a preferred embodiment of the packaging box for transporting glass substrates of the present invention. The packaging box 40 includes a box body 42 and a cover body 44 , and the box body 42 and the cover body 44 are nested together to form a receiving space (not shown), and the receiving space is used for receiving glass substrates to be transported.

[0028] The box body 42 includes an outer buffer material 422 and an inner buffer material 424 . The outer buffer material 422 is located on the outside of the box body 42, the inner layer buffer material 424 is located on the inner side of the box body 42, and the outer layer buffer material 422 and the inner layer buffer material 424 are connected by four first positions. The side walls are matched with a bottom wall, the inner buffer material 424 is higher than the outer buffer material 422, and the inner buffer material 424 also encloses a rectangular st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com