Antistatic color aluminum plate and production process thereof

A production process and anti-static technology, applied in the field of aluminum plates, can solve the problems of poor anti-static, anti-scratch and wear-resistant properties, and achieve the effects of good anti-static and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

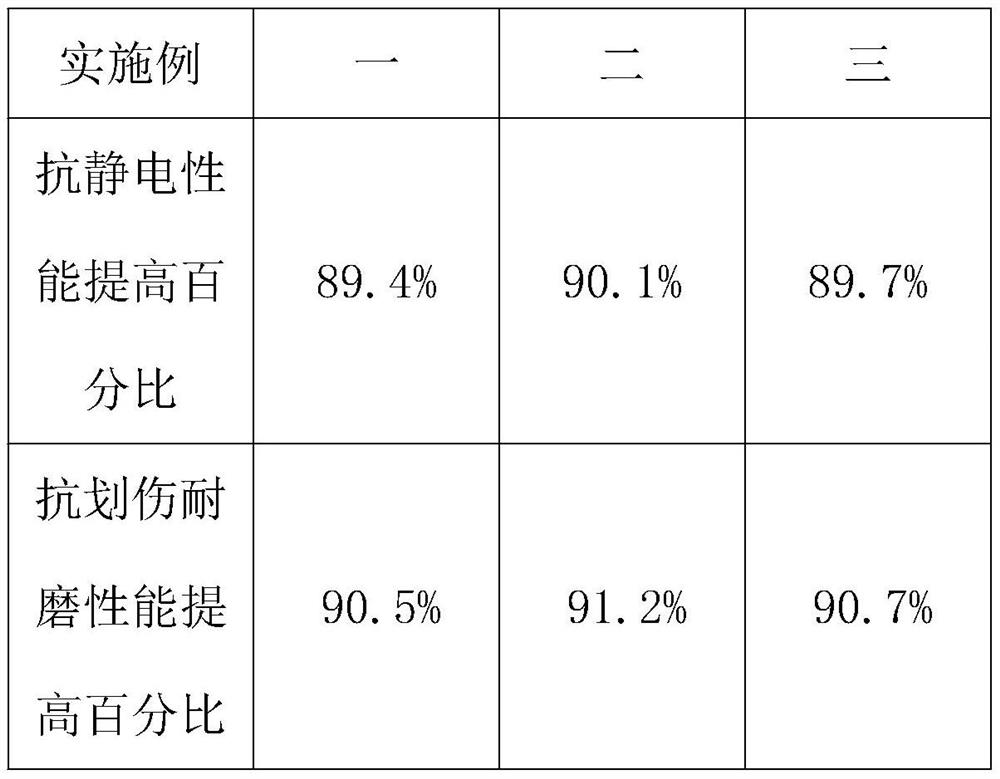

Examples

Embodiment 1

[0023] The present invention proposes an antistatic color aluminum plate and its production process, including the following raw materials in parts by weight: 30 parts of polyurethane resin, 15 parts of acrylic resin, 5 parts of titanium dioxide, 10 parts of polyvinyl acetate, ethoxylated alkanes 1 part of amino acid amine, 2 parts of polyether ester amide, 1 part of dithiocarbamate, 3 parts of hydroxyethyl fatty amine, 5 parts of polypropylene wax, 1 part of modified silicone oil, 1 part of palm wax, calcium stearate 2 parts, 1 part of nano-alumina, 1 part of pigment, 5 parts of graphene, 1 part of color retention agent;

[0024] Its preparation method comprises the following steps:

[0025] S1: Stir and mix polyurethane resin, acrylic resin, titanium dioxide, polyvinyl acetate, ethoxylated alkyl acid amine, polyether ester amide, dithiocarbamic acid, and hydroxyethyl fatty amine to obtain For antistatic raw materials, the stirring time is 1h, the stirring speed is 500r / min,...

Embodiment 2

[0030] The invention proposes an antistatic color aluminum plate and its production process, including the following raw materials in parts by weight: 40 parts of polyurethane resin, 17 parts of acrylic resin, 7 parts of titanium dioxide, 12 parts of polyvinyl acetate, ethoxylated alkanes 3 parts of amino acid amine, 4 parts of polyether ester amide, 3 parts of dithiocarbamate, 5 parts of hydroxyethyl fatty amine, 7 parts of polypropylene wax, 3 parts of modified silicone oil, 3 parts of palm wax, calcium stearate 4 parts, 3 parts of nano-alumina, 3 parts of pigment, 7 parts of graphene, 3 parts of color retention agent;

[0031] Its preparation method comprises the following steps:

[0032] S1: Stir and mix polyurethane resin, acrylic resin, titanium dioxide, polyvinyl acetate, ethoxylated alkyl acid amine, polyether ester amide, dithiocarbamic acid, and hydroxyethyl fatty amine to obtain For antistatic raw materials, the stirring time is 1.5h, the stirring speed is 550r / min...

Embodiment 3

[0037] The present invention proposes an antistatic color aluminum plate and its production process, including the following raw materials in parts by weight: 50 parts of polyurethane resin, 20 parts of acrylic resin, 10 parts of titanium dioxide, 15 parts of polyvinyl acetate, ethoxylated alkanes 5 parts of amino acid amine, 6 parts of polyether ester amide, 5 parts of dithiocarbamate, 7 parts of hydroxyethyl fatty amine, 10 parts of polypropylene wax, 5 parts of modified silicone oil, 5 parts of palm wax, calcium stearate 6 parts, 5 parts of nano-alumina, 5 parts of pigment, 10 parts of graphene, 5 parts of color retention agent;

[0038] Its preparation method comprises the following steps:

[0039] S1: Stir and mix polyurethane resin, acrylic resin, titanium dioxide, polyvinyl acetate, ethoxylated alkyl acid amine, polyether ester amide, dithiocarbamic acid, and hydroxyethyl fatty amine to obtain For antistatic raw materials, the stirring time is 2h, the stirring speed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com