Antiflaming optical diffusion polycarbonate resin composition

A technology of polycarbonate resin and resin composition, which is applied in the field of flame-retardant light-diffusing polycarbonate resin composition, and can solve problems such as undisclosed technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0183] Hereinafter, the present invention will be described in detail through examples. In addition, evaluation was performed by the following method.

[0184] The resin compositions described in Table 1 were produced by the following methods. The components in the proportions in Table 1 were weighed and uniformly mixed using a tumbler, and then the mixture was charged into an extruder to prepare a resin composition. As the extruder, a vented twin-screw extruder (KTX-30, manufactured by Kobe Steel Works, Ltd.) with a diameter of 30 mmφ was used. The strands are extruded under the condition that the cylinder temperature and the mold temperature are both 280°C and the vacuum degree of the exhaust part: 3000Pa, and then, after cooling in a water bath, the strands are cut with a granulator to obtain pellets. Use a hot air circulation dryer to dry the obtained granules at 120°C for 6 hours, then pass through an injection molding machine (IS150EN-5Y, manufactured by Toshiba Machin...

Embodiment 1~16 and comparative example 1~8

[0189] The content of each component represented by the symbol in Table 1 is as follows.

[0190] (A component)

[0191] PC-1: linear aromatic polycarbonate resin powder (Panlite L-1225WP (trade name) synthesized from bisphenol A, p-tert-butylphenol as a terminal stopper, and phosgene by interfacial polycondensation The average molecular weight is 22400, manufactured by Teijin Chemicals Co., Ltd.)

[0192] PC-2: Linear aromatic polycarbonate resin powder (L-1225WX (trade name), viscosity-average molecular weight For 19700, manufactured by Teijin Chemicals Co., Ltd.)

[0193] (B component)

[0194] B-1: bead-shaped cross-linked silicon (TOSUPAR 120 (trade name), average particle diameter 2 μm, manufactured by Toshiba Silicone Co., Ltd.)

[0195] B-2: Bead-shaped cross-linked acrylic particles (MBX-5 (trade name), average particle diameter 5 μm, manufactured by Sekisui Chemical Industry Co., Ltd.)

[0196] (C component)

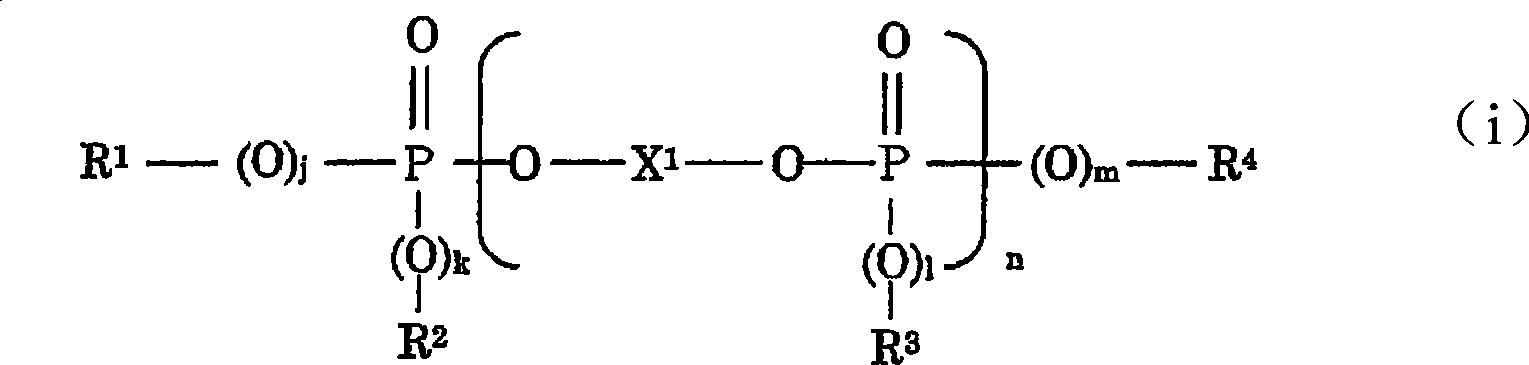

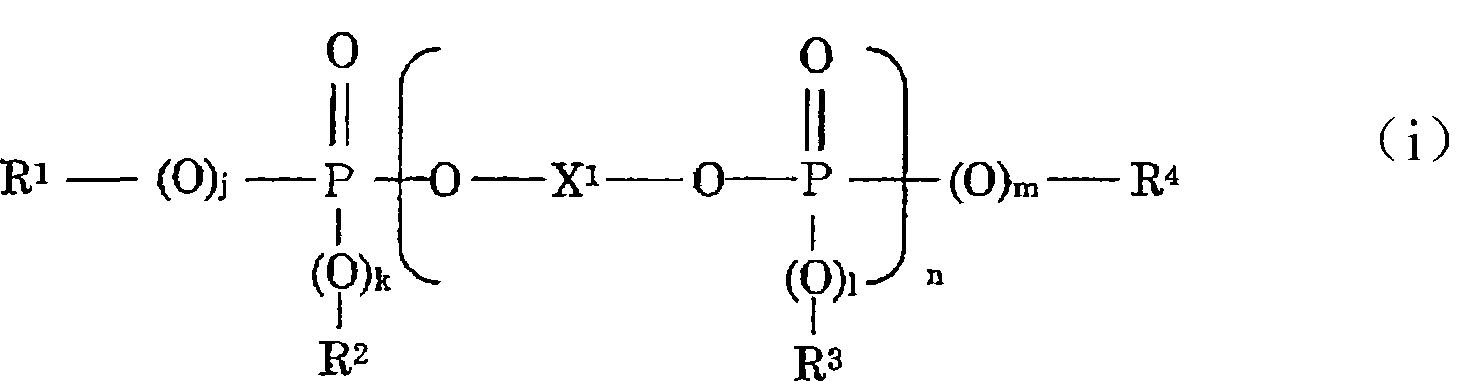

[0197] C-1: Phosphate ester mainly composed of reso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com