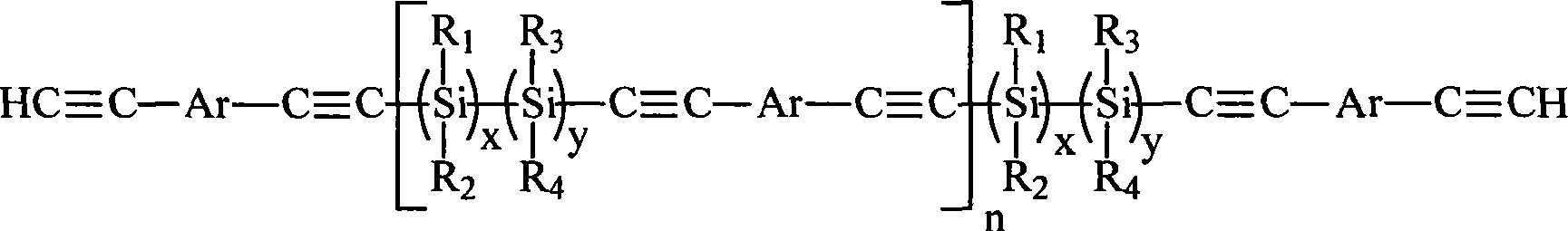

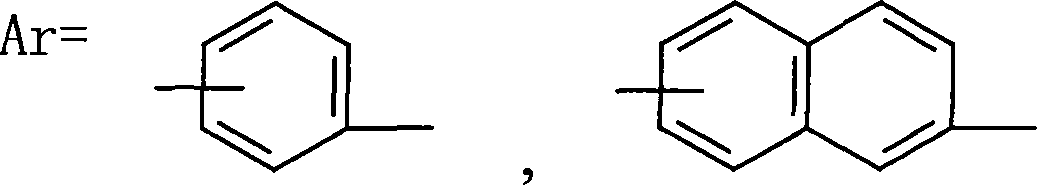

Aryne resin containing polysilicone and preparation method thereof

An arylacetylene resin and polysilane technology, applied in the field of polysilane-containing arylacetylene resin and its preparation, can solve the problems of inability to achieve thermal protection effect, high pyrolysis carbon residue rate, low shrinkage rate, etc., and achieve excellent physical and mechanical properties. Performance and heat resistance, low viscosity, good resin processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] (1) Preparation of 1,2-dichlorotetramethyldisilane (III)

[0088] Add anhydrous aluminum trichloride (54g, 410mmol) and dichloromethane (120mL) into a 500mL four-necked flask equipped with a stirring device, a constant pressure funnel, a thermometer and a condenser tube, and then add acetyl chloride (28.7g , 410mmol), about 30min to finish dripping, and stir until a yellow homogeneous solution is formed after the dropwise addition;

[0089] Then the resulting yellow homogeneous solution was added dropwise to a solution of hexamethyldisilane (29.3g, 200mmol) in dichloromethane (80mL) under ice-bath and stirring conditions. In a 500mL four-necked flask with a condenser tube, reflux at 40°C for 12 hours after the dropwise addition;

[0090] Most of the dichloromethane was removed by distillation, and the resulting product was extracted three times with n-hexane. After distillation, 56.53 g of colorless and transparent 1,2-dichlorotetramethyldisilane liquid (III) was obtai...

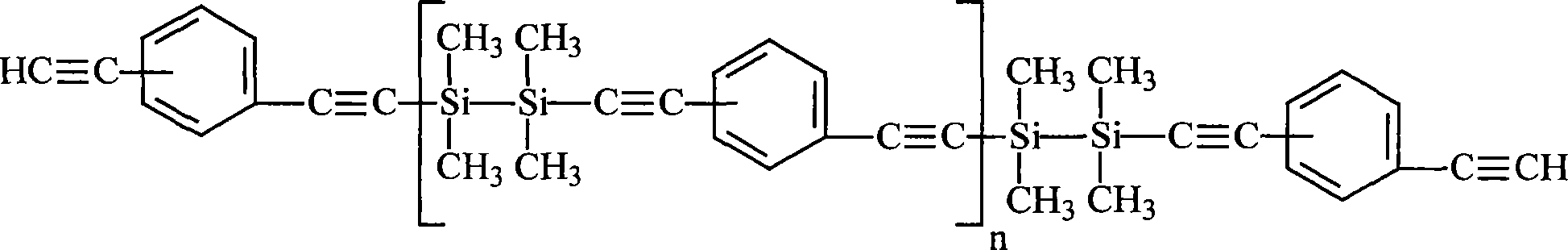

Embodiment 2

[0102] Preparation of polysilane-containing aryne resin (PSIII-AR-2)

[0103] Add treated magnesium powder (4.36g, 182mmol) and THF (50mL) into a 500mL four-necked flask equipped with a stirring device, a constant pressure funnel, a thermometer, and a condenser, protect it with nitrogen, and slowly add bromine dropwise through a constant pressure funnel. The mixed solution of ethane (18.00g, 165mmol) and THF (50mL) was added dropwise for 1.5h, and then refluxed for 1.5h to obtain a gray-black ethyl Grignard reagent;

[0104] A mixed solution of diethynylbenzene (9.47g, 75mmol) and THF (50mL) was added dropwise under cooling in an ice-water bath, the reaction mixture gradually changed from grayish black to white, the addition was completed within 1h, and then refluxed for 2h;

[0105] Under cooling in a water bath, slowly add a mixed solution of 1,2-dichlorotetramethyldisilane (III) (10.86 g, 60 mmol) and THF (50 mL) through a constant-pressure funnel for about 1 h;

[0106] A...

Embodiment 3

[0113] Preparation of polysilane aryne resin (PSIII-AR-3)

[0114] Add treated magnesium powder (4.36g, 182mmol) and THF (50mL) into a 500mL four-necked flask equipped with a stirring device, a constant pressure funnel, a thermometer, and a condenser, protect it with nitrogen, and slowly add bromine dropwise through a constant pressure funnel. The mixed solution of ethane (18.00g, 165mmol) and THF (50mL) was added dropwise for 1.5h, and then refluxed for 1.5h to obtain a gray-black ethyl Grignard reagent;

[0115] A mixed solution of diethynylbenzene (9.47g, 75mmol) and THF (50mL) was added dropwise under cooling in an ice-water bath, the reaction mixture gradually changed from grayish black to white, the addition was completed within 1h, and then refluxed for 2h;

[0116] Under cooling in a water bath, a mixed solution of 1,2-dichlorotetramethyldisilane (III) (12.22 g, 67.5 mmol) and THF (50 mL) was slowly added through a constant pressure funnel for about 1 h. After the dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com