Fiber-reinforced pure inorganic flame retardant foam composite and preparation method thereof

An inorganic flame-retardant and fiber-reinforced technology, which is applied in ceramic products, other household appliances, applications, etc., can solve the problems that the designability of composite materials cannot be fully utilized, the uniformity of dispersion is not easy to be guaranteed, and the use range of foam boards is limited. , to achieve the effect of strong designability, low cost, and orderly arrangement of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

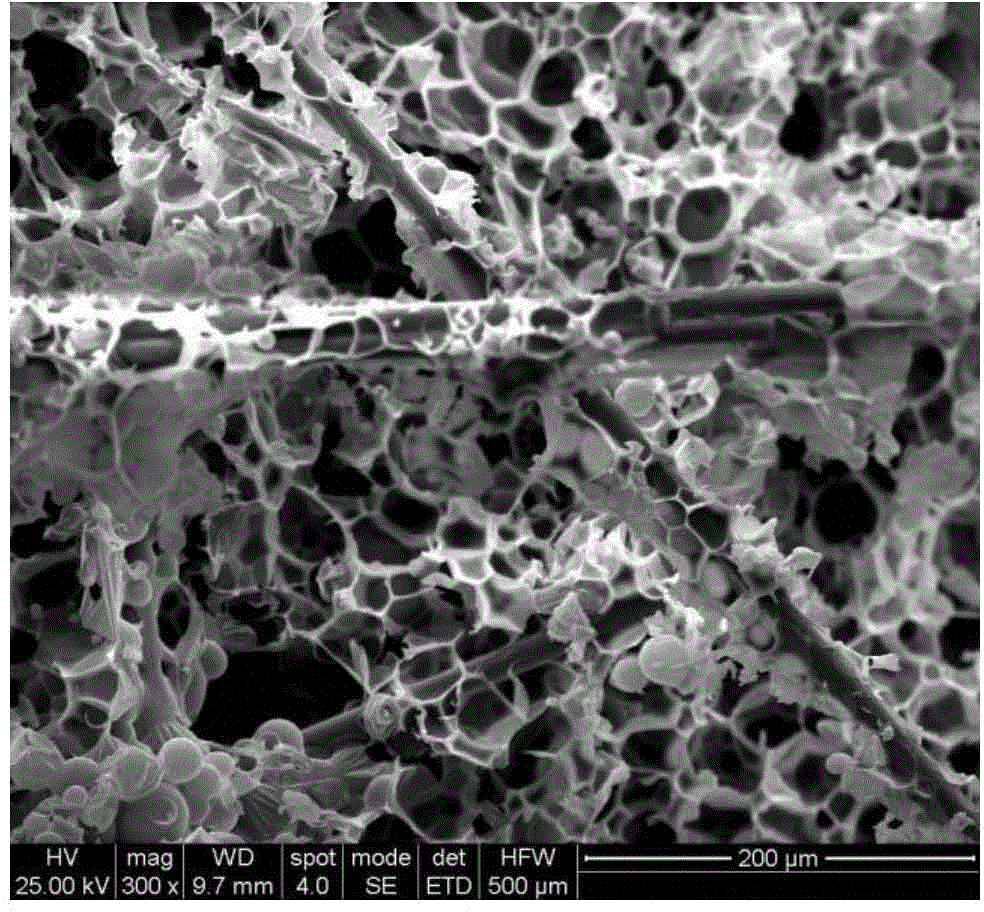

Image

Examples

Embodiment 1

[0032] Adopt 8mm thick glass fiber needle-punched felt as reinforcement phase, cut into 150mm * 200mm rectangle; Take 20g microcapsule foaming agent with starting temperature at 120 ℃, add 200g solid phase mass content to be 40% water glass solution, Mix the two evenly to form a suspension and put the impregnating agent in a rectangular container; place the above-mentioned glass fiber needle felt in the suspension and take it out after fully infiltrating, and use a double-roller extrusion device to drain the excess resin on the fiber felt to obtain the density. The fiber mat-impregnating agent homogeneous body that does not change; hang the glass fiber needle felt-impregnating agent composite vertically in a high-temperature blast drying oven at 140°C for 30 minutes for foaming expansion and dehydration curing, and then dry at 700 ℃ high-temperature furnace treatment for 1 h to obtain a quartz glass fiber reinforced quartz-based foam composite material plate. The thickness of ...

Embodiment 2

[0034]Use 8mm thick basalt fiber needle felt as the reinforcing phase, cut into 200mm×200mm square; weigh 25g of microcapsule foaming agent with an initiation temperature of 140°C, add 250g of aluminum dihydrogen phosphate solution with a solid phase mass content of 40% , mix the two evenly to form a suspension impregnating agent and place it in a rectangular container; put the above-mentioned basalt fiber needle felt in the suspension and fully infiltrate it, then take it out, use twin-roll extrusion equipment to drain the excess resin on the fiber felt, Obtain a fiber mat-impregnating agent homogeneous body with no change in density; hang the basalt fiber needle felt-impregnating agent composite vertically in a high-temperature blast drying oven at 160°C for 30 minutes, perform foaming expansion and dehydration curing, and then Treat it in a high-temperature furnace at 600°C for 1 hour to obtain a basalt fiber-reinforced aluminum phosphate-based foam composite sheet. The thi...

Embodiment 3

[0036] Adopt 5mm thick alumina fiber felt as reinforcement phase, cut into 200mm×200mm rectangle; Weigh 25g microcapsule foaming agent with starting temperature at 120°C, add 250g of silica sol with solid phase mass content of 40%, mix the two Mix evenly to form a suspension impregnating agent and place it in a rectangular container; place the above-mentioned alumina fiber felt in the microcapsule-silica sol suspension and fully infiltrate it, then take it out, and use a double-roller extrusion device to drain the excess resin on the fiber felt. Obtain a fiber mat-impregnating agent homogeneous body with no change in density; hang the aluminum oxide fiber mat-impregnating agent composite vertically in a high-temperature blast drying oven at 140°C for 30 minutes for foaming expansion and dehydration curing, and then After being treated in a high-temperature furnace at 700°C for 1 hour, a quartz glass fiber reinforced quartz-based foam composite material plate is obtained. The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com