Modified chloroprene rubber V band and method for preparing same

A chloroprene rubber and modification technology is applied in the field of carbon nanotube composite additive modified chloroprene rubber V-belt and its preparation field. Good heat resistance, antistatic and flame retardant properties improve, reduce the effect of fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

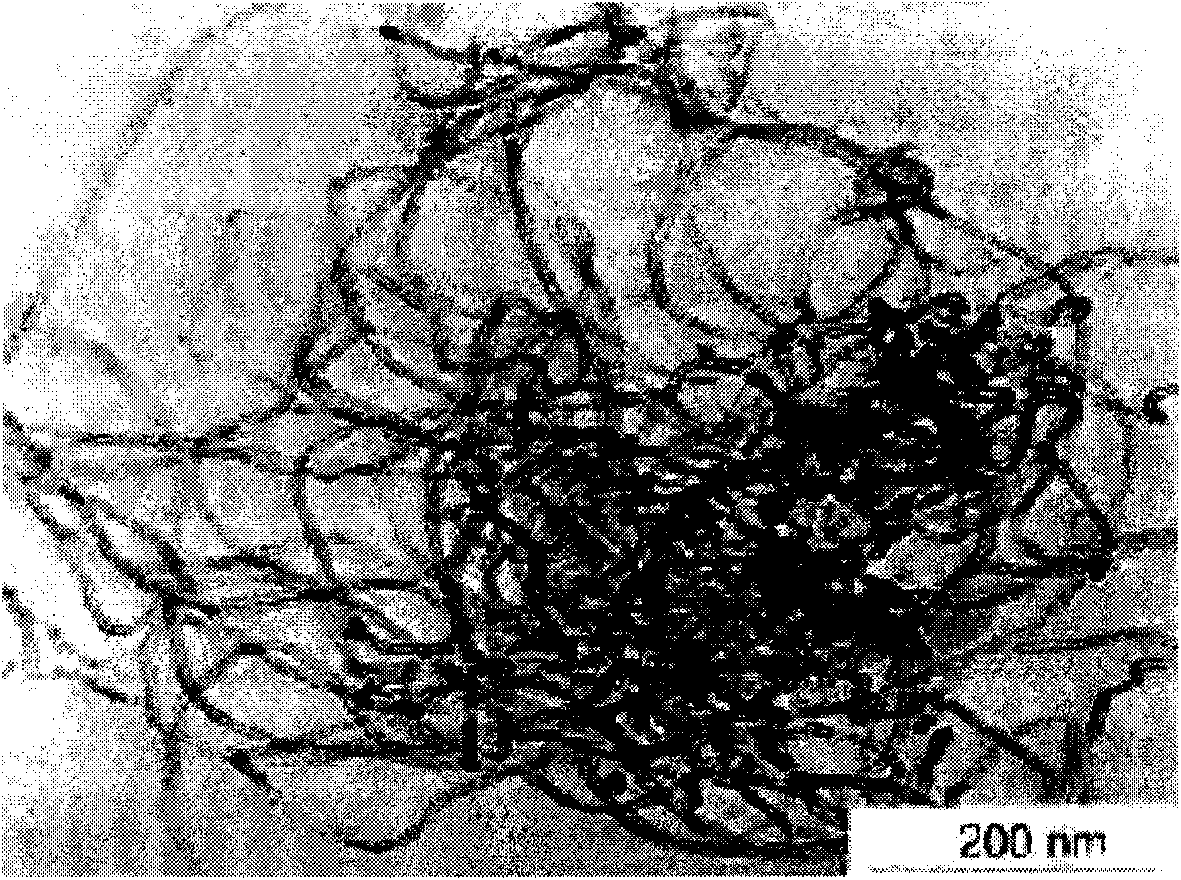

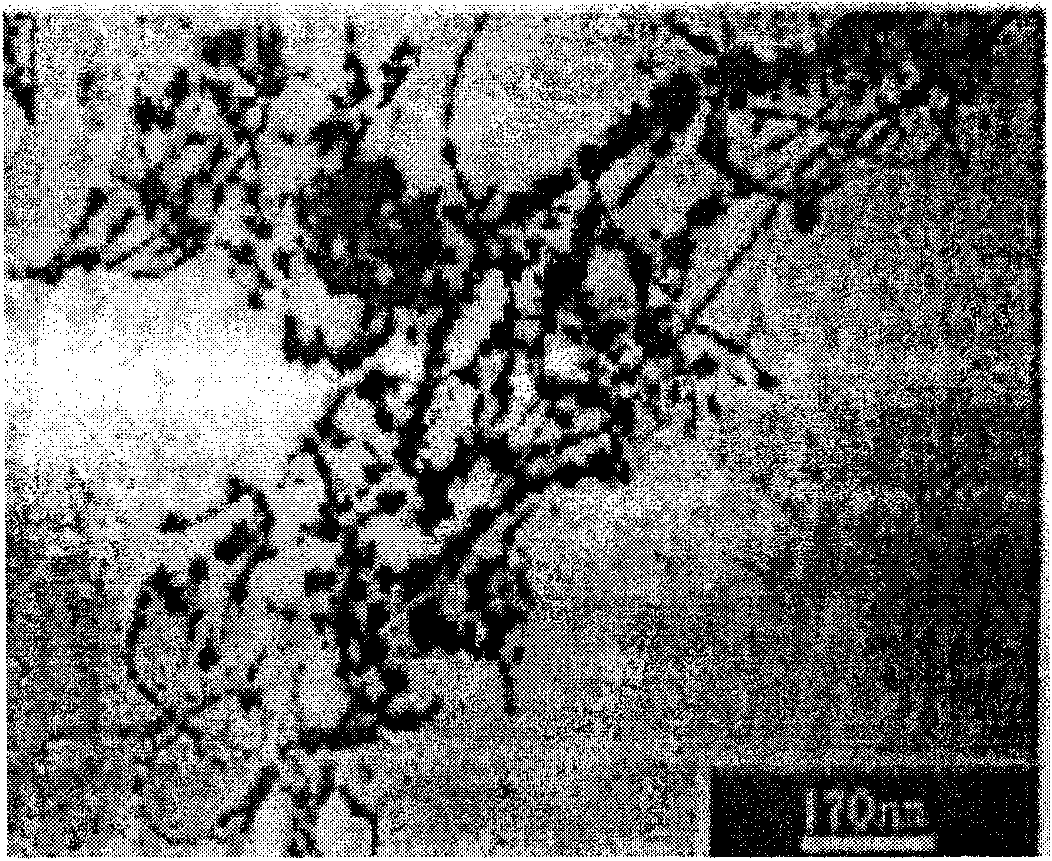

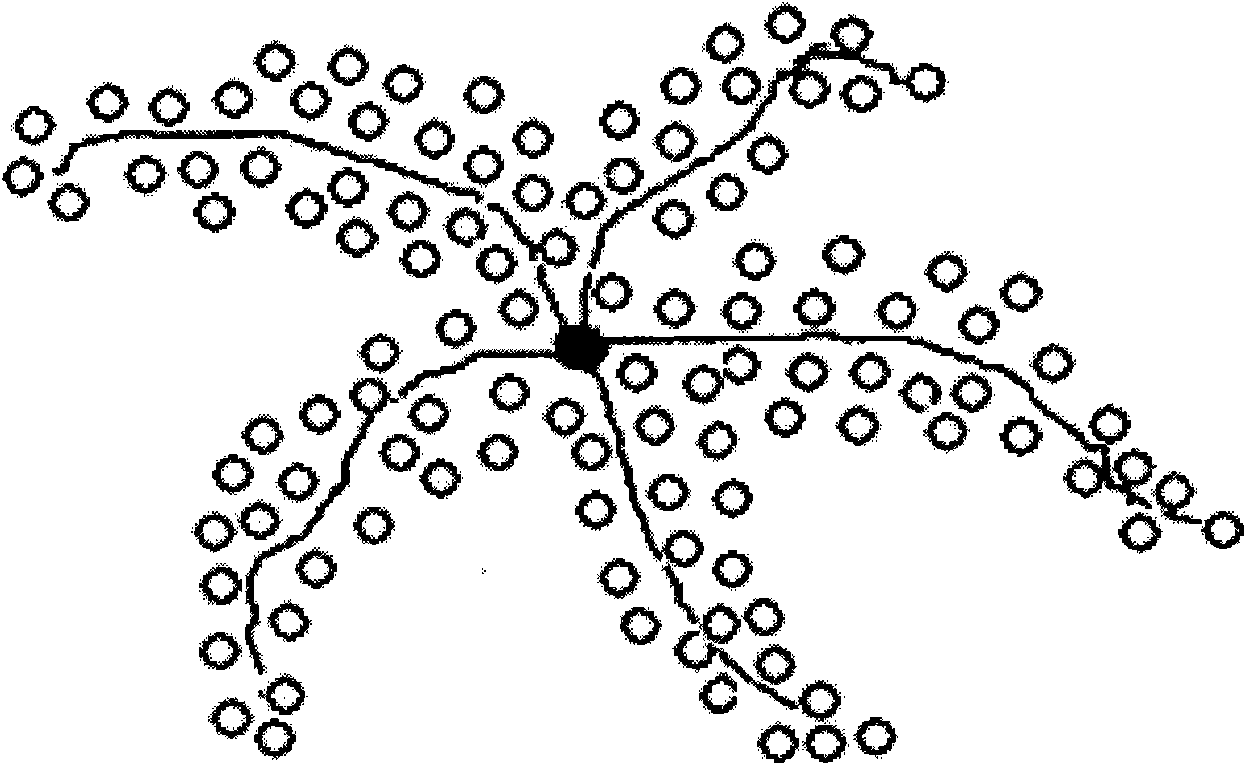

[0044] The carbon nanotubes are refluxed and purified with nitric acid with a concentration of 98% by mass, and are combined with ultrasonic vibration to prepare the nitric acid-modified carbon nanotubes.

[0045] Take the above 20 parts by weight of nitric acid modified carbon nanotubes, 10 parts by weight of carbon black obtained by soaking in hydrochloric acid with a concentration of 5% by mass and then vacuum drying at 10°C, and 2 parts by weight of phosphorus trioxide and compound them by wet method Composite additives are prepared.

[0046] Put 100 parts by weight of chloroprene rubber in a double-roller plastic mixer, the temperature of the rollers is 45°C, the temperature difference between the front and rear rollers is 10°C, the distance between the rollers is 1mm, the speed ratio of the front and rear rollers is 1:1.27, and after 10min of mastication, let it stand in the air. After cooling, add 15 parts by weight of sulfur and the above-mentioned composite additives,...

Embodiment 2

[0048] The carbon nanotubes are refluxed and purified with nitric acid with a concentration of 98% by mass, and are combined with ultrasonic vibration to prepare the nitric acid-modified carbon nanotubes.

[0049] Take the above 50 parts by weight of nitric acid modified carbon nanotubes, 10 parts by weight of carbon black obtained by soaking in hydrochloric acid with a mass percent concentration of 20% and then vacuum drying at 20 ° C, and 5 parts by weight of phosphorus trioxide. Composite additives are prepared.

[0050] Put 100 parts by weight of chloroprene rubber in a double-roller masticator, the roller temperature is 50°C, the temperature difference between the front and rear rollers is 11°C, the roller distance is 0.9mm, and the front and rear roller speed ratio is 1:1.27. After 15 minutes of mastication, let it stand in the air After cooling, add 12 parts by weight of sulfur and the above-mentioned composite additives, pre-mix for a few minutes in a two-roller mill w...

Embodiment 3

[0052] The carbon nanotubes are refluxed and purified with nitric acid with a concentration of 98% by mass, and are combined with ultrasonic vibration to prepare the nitric acid-modified carbon nanotubes.

[0053] Take the above 35 parts by weight of nitric acid-modified carbon nanotubes, 20 parts by weight of the carbon black obtained by vacuum drying at 55° C. and 2 parts by weight of phosphorus pentoxide by dry method Composite to make composite additives.

[0054] Put 100 parts by weight of chloroprene rubber in a double-roller plastic mixer, the temperature of the rollers is 55°C, the temperature difference between the front and rear rollers is 12°C, the distance between the rollers is 1.2mm, the speed ratio of the front and rear rollers is 1:1.27, and it is masticated for 15 minutes and left to stand in the air After cooling, add 18 parts by weight of sulfur and the above-mentioned composite additives, and pre-mix for several minutes in a two-roller masticator with a rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com