Active carbon fiber composite material and preparation method thereof

A technology of activated carbon fiber and activated carbon fiber cloth, which is applied in the field of activated carbon fiber composite materials and its preparation, can solve the problems of cumbersome multi-functional fabrics, many layers of fabrics, and heavy finished products, and achieve simple and feasible preparation methods, good flexibility, The effect of small weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

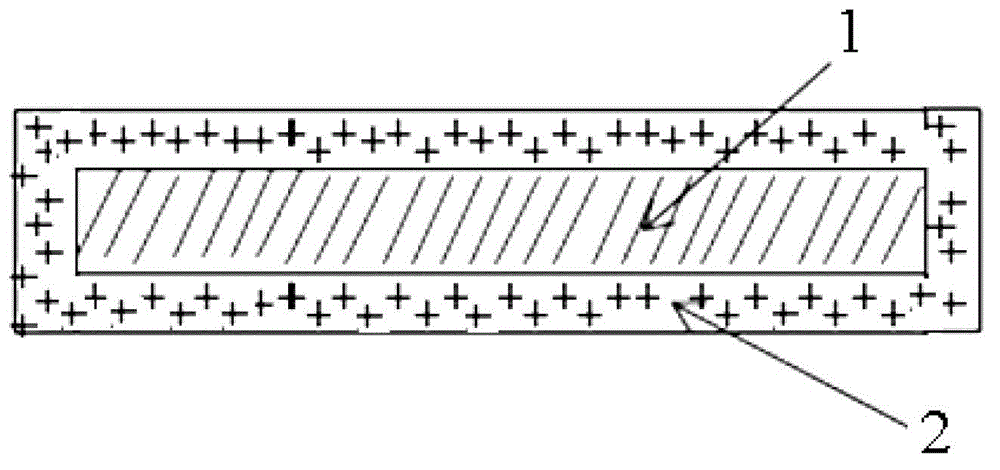

Image

Examples

Embodiment 1

[0047] Mix 156g (0.75mol) ethyl orthosilicate, 204g (4.43mol) absolute ethanol and 40g (2.22mol) deionized water, stir at 25°C for 40min to make it evenly mixed; the mass fraction of 0.1mL is 37% hydrochloric acid (1.20×10 -3 mol) was added to 20g (1.11mol) deionized water, mixed evenly and quickly added dropwise to the above precursor solution, stirred evenly and aged for 6h to obtain SiO 2 Acidic sol; Ammonia water with a mass fraction of 28% was added dropwise to the acidic sol until the pH value was 7.4 to obtain SiO 2 Alkaline sol; the thickness is 0.3mm, the specific surface area is 1500m 2 / g of PAN-based activated carbon fiber plain cloth was immersed in the above-mentioned alkaline sol, stood for 10 h, and dried at 70 ° C for 30 h to obtain a single-layer activated carbon fiber composite fabric. SiO in the composite fabric 2 The content is 16wt%, and the specific surface area of the composite fabric is 1253m 2 / g, the gram weight is 96g / m 2 , The warp breaking ...

Embodiment 2

[0049] Mix 122g (0.80mol) of methyl orthosilicate, 190g (4.13mol) of absolute ethanol and 33g (1.83mol) of deionized water, stir at 30°C for 30min to make it evenly mixed, and the mass fraction of 0.025mL is 98% of sulfuric acid (4.60×10 -4 mol) was added to 16.5g (0.915mol) deionized water, mixed evenly and quickly added dropwise to the above precursor solution, stirred evenly and aged for 6h to obtain SiO 2 Acidic sol; the mass fraction of 30% NaOH solution was added dropwise to the acidic sol until the pH value was 7.8 to obtain SiO 2 Alkaline sol; the thickness is 0.5mm, the specific surface area is 1650m 2 / g of PAN-based activated carbon fiber twill cloth was immersed in the above-mentioned alkaline sol, left to stand for 10 h, and dried at 60 ° C for 30 h to obtain a single-layer activated carbon fiber composite fabric. SiO in the composite fabric 2 The content is 21wt%, and the specific surface area of the composite fabric is 1163m 2 / g. Gram weight is 122g / m 2...

Embodiment 3

[0051] Mix 90g (0.50mol) of methyltriethoxysilane, 210g (6.55mol) of anhydrous methanol and 36g (2.00mol) of deionized water, stir at 30°C for 30min to make it evenly mixed,

[0052] Dissolve 0.18g (0.02mol) of oxalic acid in 18g (1.00mol) of deionized water and quickly add it dropwise to the above precursor solution, stir evenly and age for 10h to obtain SiO 2 Acidic sol; Ammonia water with a mass fraction of 28% was added dropwise to the acidic sol until the pH value was 7.8 to obtain SiO 2 Alkaline sol; the thickness is 0.3mm, the specific surface area is 1500m 2 / g of PAN-based activated carbon fiber plain weave cloth was immersed in the above-mentioned alkaline sol, stood for 10 h, and dried at 60 ° C for 30 h to obtain a single-layer activated carbon fiber composite fabric. SiO in the composite fabric 2 The content is 19wt%, and the specific surface area of the composite fabric is 1012m 2 / g, the gram weight is 105g / m 2 , The warp breaking strength is 241N, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com