Polyolefin composite material for butterfly optical cable sheath and preparation method thereof

A butterfly-shaped optical cable and composite material technology, which is used in cables, insulated cables, plastic/resin/wax insulators, etc. to achieve good wrapping force, improved flame retardant properties, and smooth appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

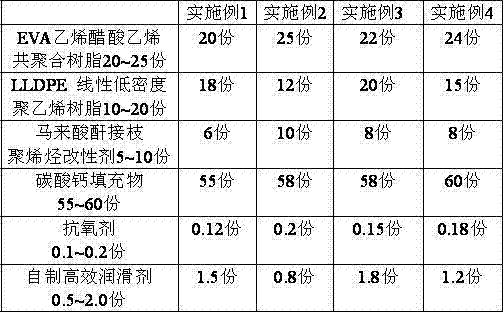

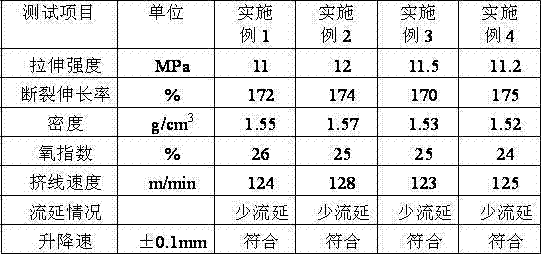

[0031] Embodiment: a polyolefin composite material for a butterfly cable sheath, said polyolefin composite material for a butterfly cable sheath is composed of the following components in parts by weight, as shown in Table 1:

[0032] Table 1

[0033]

[0034] The above EVA ethylene vinyl acetate copolymer resin requires VA content of 25~30%, MI value of 6~10g / 10min;

[0035] The above-mentioned LLDPE linear low density polyethylene resin has a density of 0.912g / cm 3 , MI value 1~3.5g / 10min, preferably MI value 2g / 10min;

[0036] The grafted resin substrate of the above-mentioned maleic anhydride grafted polyolefin modifier is PE or PE / POE, and the grafting rate is 0.2~0.8%;

[0037] Described calcium carbonate filler, embodiment 1 is light calcium carbonate, embodiment 2 is 2500 order heavy calcium carbonate, embodiment 3 is light calcium carbonate, embodiment 4 is 2500 order heavy calcium carbonate;

[0038] The self-made high-efficiency lubricant is composed of high m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com