Processing method for producing anti-static sheet through continuous process

A process method and anti-static technology, which is applied in the field of anti-static sheet production, can solve the problems of reduced productivity, high-power extension and other physical energy reduction, and achieve the effect of high extensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

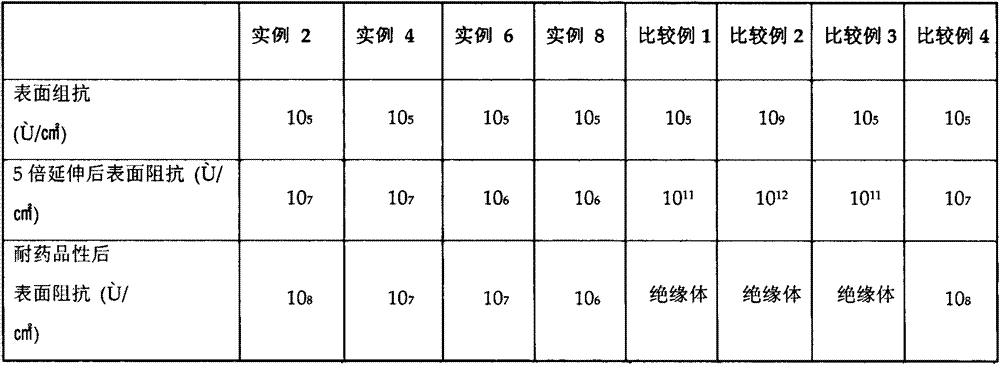

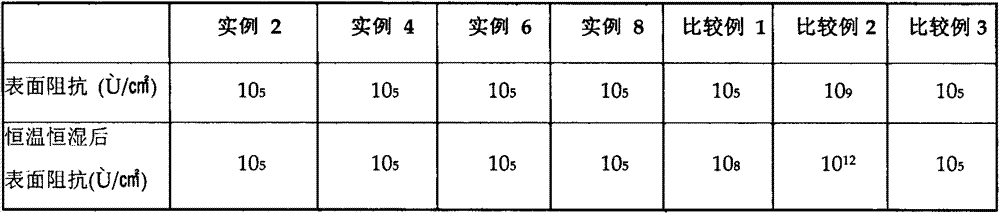

Examples

example 1

[0048] 1-1. Carbon nanotube (length 30 μm, width 10nm multi-wall) 2% by weight, acrylic polymer binder (Carboset CR780, BFGoodrich Co.) 15% by weight, isopropanol 50% by weight, interest rate cellulose 31 % by weight, dispersant (polymer anion, HPA-328, Yeungsan Co.) 1% by weight, fluidity improver (HPA-538, Yeungsan Co.) 1% by weight, antistatic liquid is produced according to the above proportioning ratio.

[0049] 1-2. After the polyethylene terephthalate (PET) resin is extruded through the T-steel die extrusion process (the temperature of the extruder is 150-170 ° C), it will be produced by passing through a single rod and a cooling roll. A PET sheet with a thickness of 1 mm is coated on one side with the above-mentioned antistatic kiss roll coating liquid to form a coating with a thickness of 0.1 μm (coating thickness after drying), and thermally cured at a temperature of 60-80 ° C . After kiss roll coating on one side, roll coating is used to coat the other side of the ...

example 2

[0051] The antistatic sheet produced in the above example 1 was vacuum formed at a temperature of 150-180° C., and stretched 5 times to produce an antistatic tray.

example 3

[0053] Example 1-1 excludes the addition of 1% by weight of aziridine as a crosslinking agent, and then prepares an antistatic liquid in the same manner, and then produces an antistatic sheet in the same manner as in Example 1-2. The surface impedance is measured according to the method of ASTM D257.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com