Interstage cable connection method for high overload electronic equipment

A technology of electronic equipment and connection method, which is applied in the direction of connection, connection, and attack equipment where permanent deformation works. The effect of improving the anti-overload performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

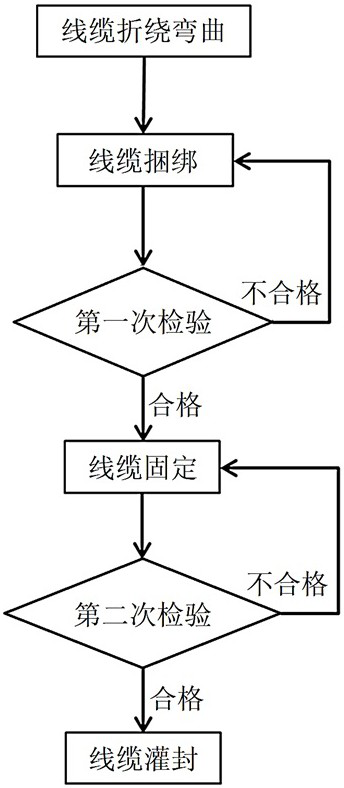

[0029] like figure 1 As shown, the inter-stage cable connection method for high-overload electronic equipment in this embodiment includes the following steps:

[0030] S10. The cable is folded and bent;

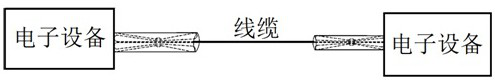

[0031] like figure 2 As shown in the figure, the cable is bent twice at the connection outlet, and the bending radius of different types of cables is determined according to the specifications of the type of cable;

[0032] S20. Cable bundle;

[0033] After all the cables are folded and bent, at the middle of the folded cable, use a thin wire to bind the entire folded cable to obtain a binding structure;

[0034] S30. The first inspection;

[0035] Check the bundling structure and tear it manually. When the thin wire does not slide up and down, and the cable at the bundling does not move left and right or up and down, the inspection is qualified; otherwise, return to step S20 until the inspection is qualified;

[0036] S40. Cable fixing;

[0037] Measure the total leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com