Production technology of anti-static fabric

An anti-static fabric and production process technology, applied in the treatment of textile materials, biochemical fiber treatment, fabric surface trimming, etc., can solve the problems of difficult anti-static performance, anti-static properties of difficult fabrics, and singleness, and improve anti-static properties. and anti-static durability, preventing the cotton fiber from being too soft, and improving anti-static properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a kind of production technology of antistatic fabric, comprises the following steps:

[0030] S1. Twisting conductive yarns and polyester-cotton yarns together to obtain conductive yarns, using polyester-cotton yarns as warp and weft yarns, weaving conductive yarns at intervals during the weaving process to obtain antistatic gray fabrics; conductive yarns are nylon-based conductive fiber filaments, and twisted The twist of the obtained conductive yarn is 30-50 twists / 10cm. The distance between the conductive yarns in the antistatic gray fabric is 0.5-0.8cm in the warp direction, and the distance between the conductive yarns in the weft direction is 0.8-1.5cm. .

[0031] S2, singeing, setting; the speed of the singeing is 110m / min, the flame temperature is 1020°C; the setting temperature is 156°C.

[0032] S3, dissolving the dye in water, stirring evenly to obtain a dye solution with a concentration of 60g / L, adjusting the pH of the solu...

Embodiment 2

[0036] The present embodiment provides a kind of production technology of antistatic fabric, comprises the following steps:

[0037] S1. Conductive yarns are twisted together with polyester-cotton yarns to obtain conductive yarns. Polyester-cotton yarns are used as warp and weft yarns. During the weaving process, conductive yarns are woven at intervals to obtain antistatic gray fabrics; the conductive yarns are polyester-based conductive fiber filaments and twisted. The twist of the obtained conductive yarn is 30-50 twists / 10cm. The distance between the conductive yarns in the antistatic gray fabric is 0.5-0.8cm in the warp direction, and the distance between the conductive yarns in the weft direction is 0.8-1.5cm. .

[0038] S2. Singeing and setting; the speed of the vehicle during singeing is 115m / min, the flame temperature is 1040°C; the setting temperature is 157°C.

[0039] S3, dissolving the dye in water, stirring evenly to obtain a dye solution with a concentration of...

Embodiment 3

[0043] The present embodiment provides a kind of production technology of antistatic fabric, comprises the following steps:

[0044] S1. Twisting conductive yarns and polyester-cotton yarns together to obtain conductive yarns, using polyester-cotton yarns as warp and weft yarns, weaving conductive yarns at intervals during the weaving process to obtain antistatic gray fabrics; black carbon fiber conductive filaments of conductive yarns, obtained by twisting The twist of the conductive yarn is 30-50 twists / 10cm. The distance between the conductive yarns in the antistatic gray fabric is 0.5-0.8cm in the warp direction, and the distance between the conductive yarns in the weft direction is 0.8-1.5cm. .

[0045] S2, singeing, setting; the speed of the singeing is 120m / min, the flame temperature is 1050°C; the setting temperature is 160°C.

[0046] S3, dissolving the dye in water, stirring evenly to obtain a dye solution with a concentration of 70g / L, adjusting the pH of the solu...

PUM

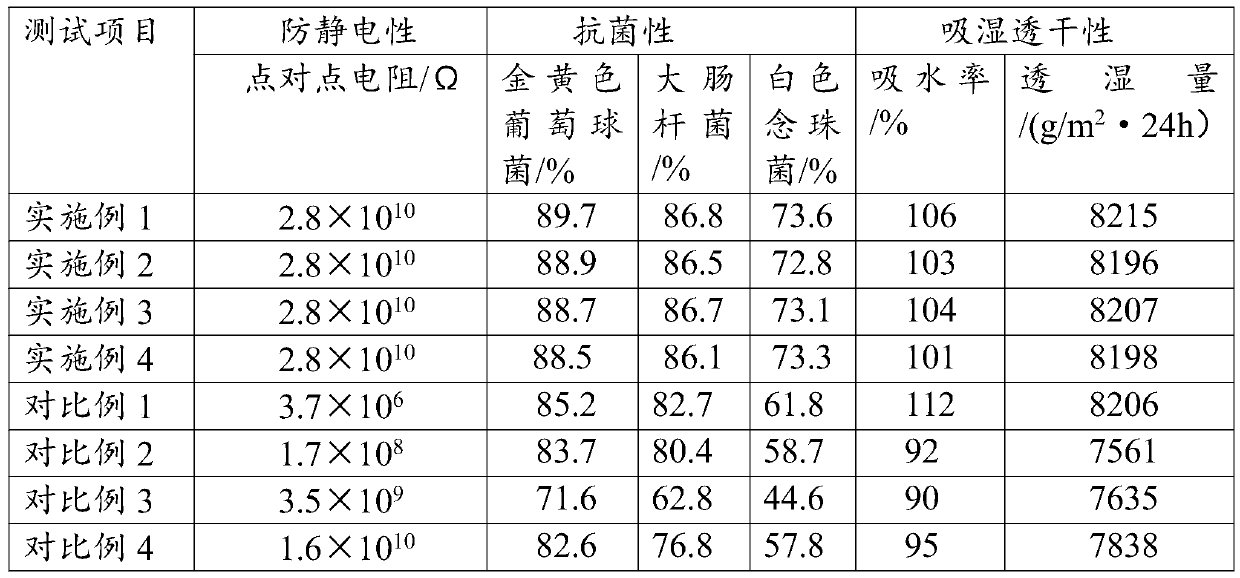

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com