High performance antistatic self-leveling epoxy floor level coating compound

A flat epoxy floor, anti-static technology, applied in epoxy resin coatings, conductive coatings, coatings and other directions, can solve the problems of affecting conductive properties, large thixotropy, and the color of carbon nanotubes is not suitable for light-colored systems. The effect of improving overall performance and improving toughness

Active Publication Date: 2019-02-01

MIANYANG HUILI EPOXY ENG

View PDF7 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These materials have their own advantages and disadvantages. For example, conductive powder is generally used for surface treatment of fillers, but it will affect the conductivity after a long time or wear; ordinary antistatic agents are easy to migrate to the surface and then consumed by friction; The darker color of carbon nanotubes is not suitable for light-colored systems, and for self-leveling systems, its thixotropy will affect the fluidity of the top coat, and the self-leveling effect cannot be achieved; while carbon fibers are easy to float on the surface due to their lighter specific gravity. Topcoating Surfaces Affects Connectivity and Appearance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0029]

[0030]

Embodiment 2

[0032]

Embodiment 3

[0034]

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

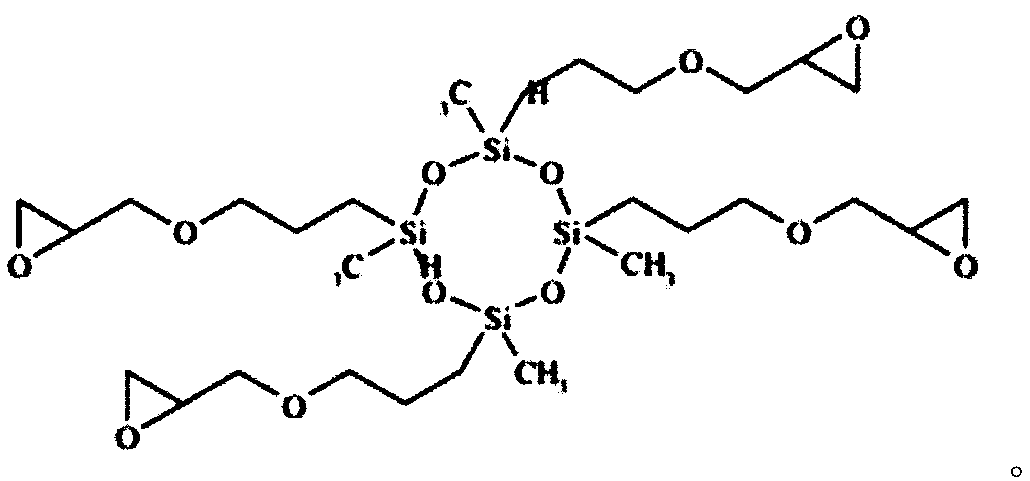

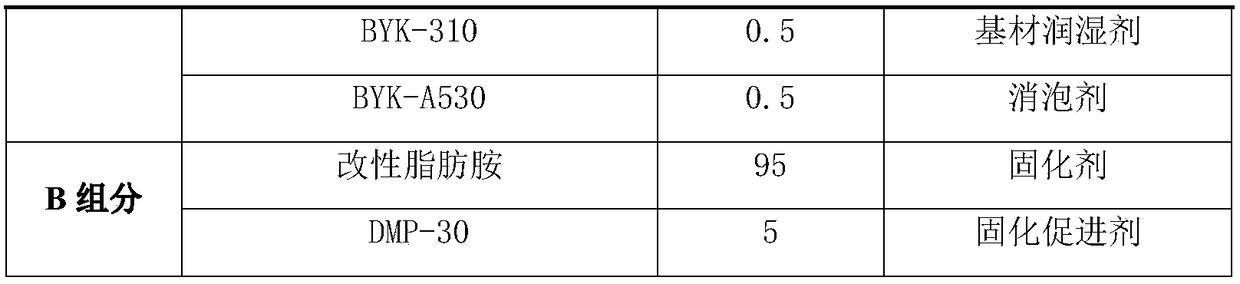

The invention discloses a high performance antistatic solvent-free self-leveling epoxy floor level coating compound. The compound comprises a component A and a component B. The component A comprises,by mass, 20 to 60 parts of epoxy resin, 0 to 20 parts of a reactive diluent, 2 to 10 parts of composite metal fiber slurry, 0.1 to 3 parts of an antistatic agent, 0.1 to 5 parts of a polyfunctional silicone modified epoxy compound, 30 to 60 parts of a filler, 2 to 10 parts of color paste and 0.1 to 3 parts of an aid. The component B comprises, by mass, 80 to 100 parts of a curing agent and 0 to 20parts of an accelerator. Through metal fibers and the long-acting antistatic agent, the problem of the conductive blind spot caused by the difficulty of overlapping the fibers due to the filter thickness increasing is solved and the uniform distribution of the resistance values is realized. The polyfunctional silicone modified epoxy compound can improve toughness, a drawing force, abrasion resistance, water resistance, pressure resistance and antistatic property.

Description

technical field [0001] The invention relates to an epoxy primer, in particular to a high-performance antistatic self-leveling epoxy floor surface coating compound. Background technique [0002] With the innovation of technology, the chip size is getting smaller and smaller, and the imaging definition of mobile display devices is getting higher and higher. The 100,000-level and 10,000-level have been raised to the 1000-level, 100-level or even higher. As far as the cleanliness of the production area is concerned, such as the floor, wall, and return air passageway all have this requirement. Therefore, in order to meet the needs of anti-vibration, air circulation and dust particle adhesion prevention in the clean area, waffle holes will be used in the design. Or the lattice beam is the main body to improve the cleanliness of the factory building, and these designs have higher requirements for the functionality of the epoxy floor. For these requirements, in addition to the tra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D163/00C09D5/24C08G59/38

CPCC09D163/00C08G59/38C09D5/24C08K7/06C08K5/41

Inventor 周鸿飞陆南平

Owner MIANYANG HUILI EPOXY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com